Electrothernal tube and its forming method

A molding method and electric heating tube technology, applied in the direction of the shape of the heating element, can solve the problems of affecting assembly, expansion and contraction damage, and difficulty in controlling the shape and size of the electrical connection end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

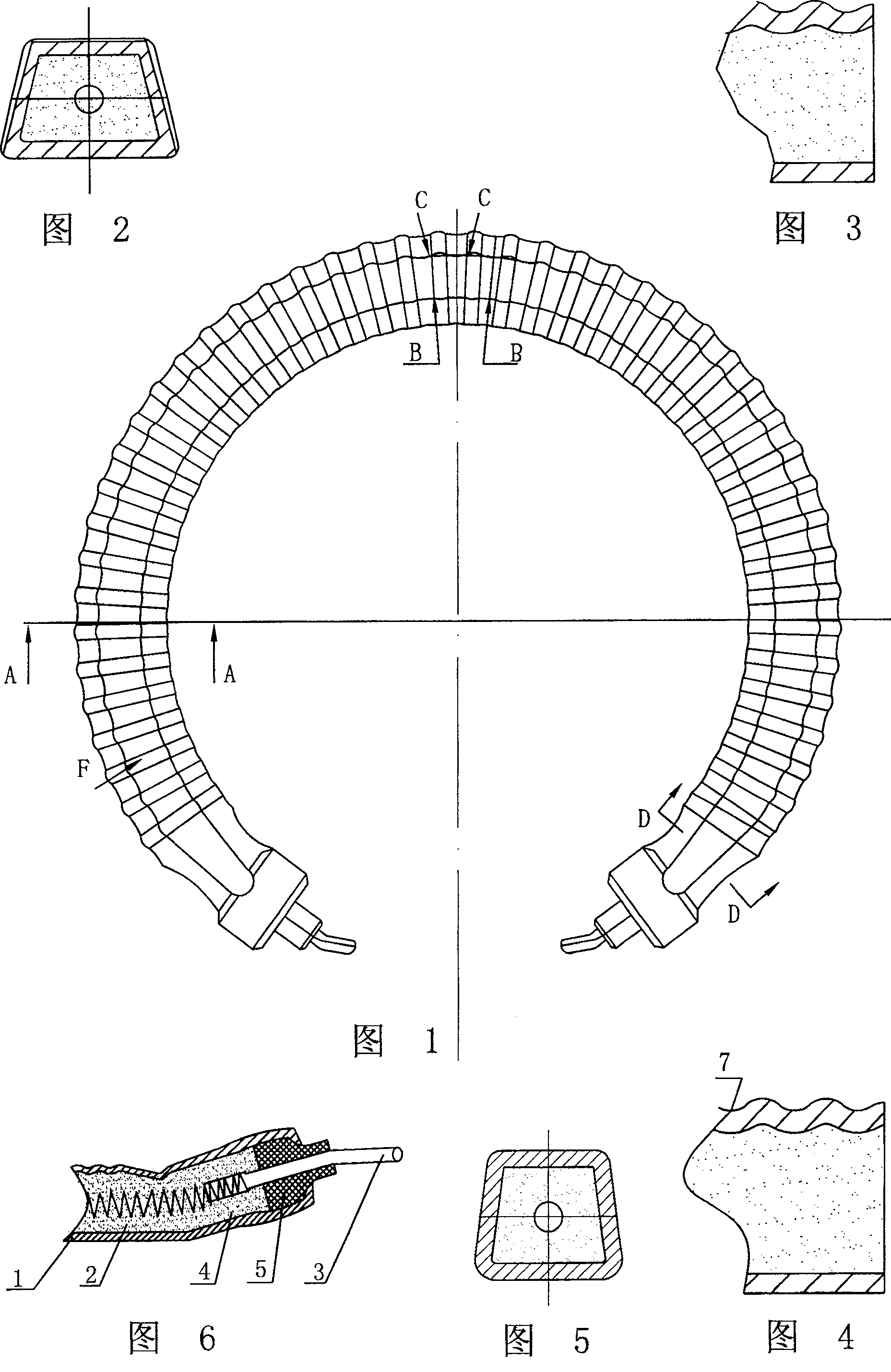

[0016] Below in conjunction with the accompanying drawings, the specific implementation of the forming method of the electric heating tube of the present invention is further described in detail:

[0017] The electric heating tube of the present invention includes a metal tube 1 , insulating powder 2 , resistance wire 4 , insulating piece 5 and metal rod 3 . The metal tube 1 is an aluminum tube, the insulating powder 2 is magnesium oxide powder, the insulating part 5 is a porcelain post, and the metal rod 3 is a steel lead post.

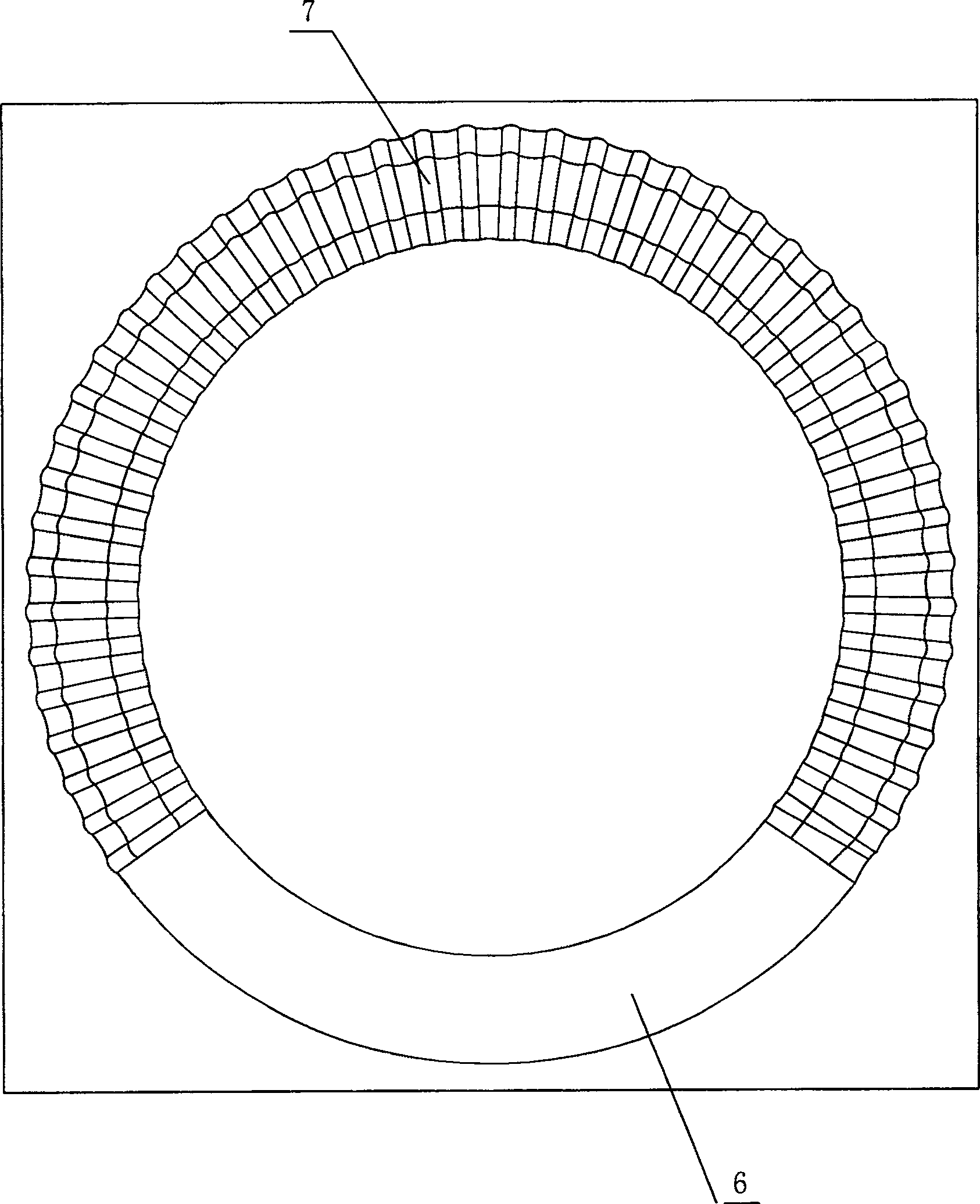

[0018] As shown in Figures 1-6, the electric heating tube is bent into a C-shape from a circular metal tube 1 with a cross-section, and then stamped to have a concave-convex structure on the surface and at least one surface is a planar structure. The advantage is that the circular metal tube 1 is easy to bend, and the distance between the internal resistance wire 4 and the tube wall of the metal tube 1 is uniform. The metal rod 3 is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com