Anti-fatigue all-hydrogel composite material as well as preparation method and application thereof

A composite material and hydrogel technology, applied in the fields of additive processing, medical science, prosthesis, etc., can solve the problems of complex simulation shape, and achieve the effect of easy industrial production and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

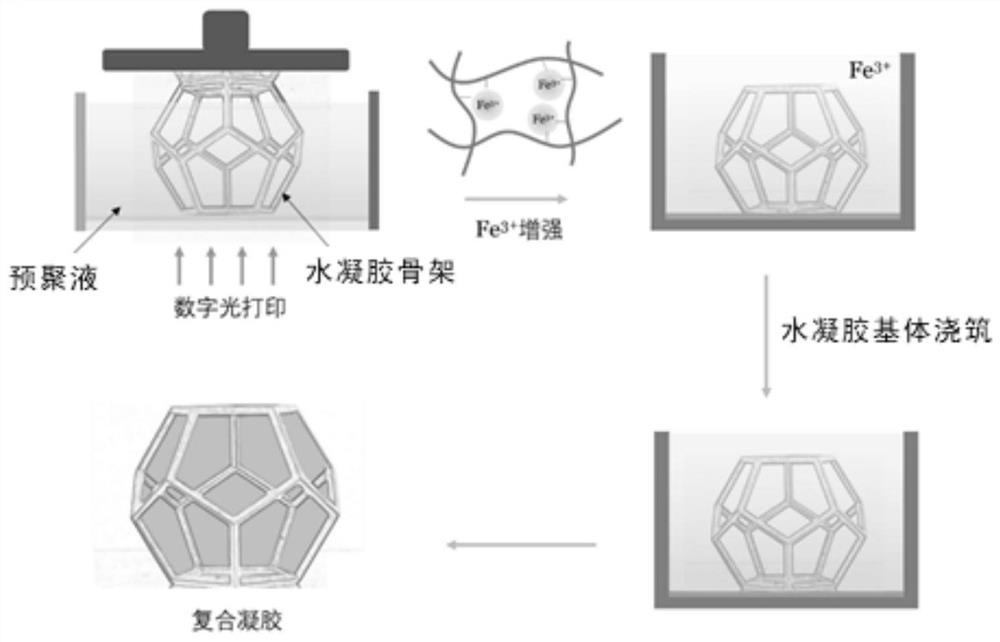

[0076] This embodiment provides a kind of anti-fatigue all-hydrogel artificial heart valve, and its preparation method is as follows:

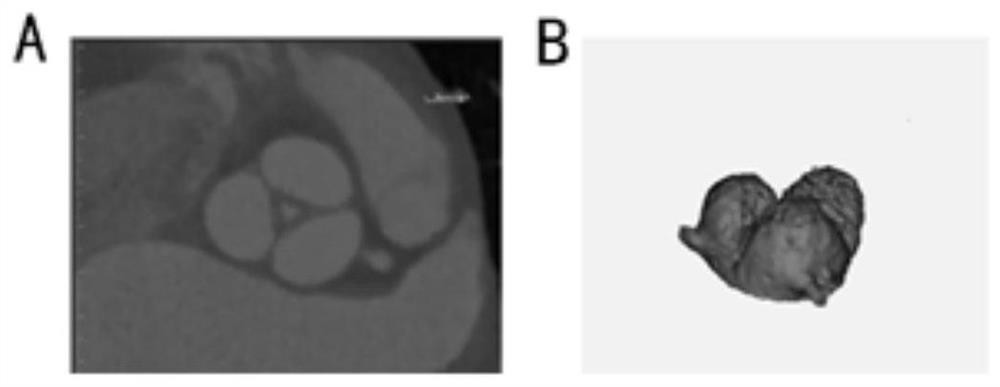

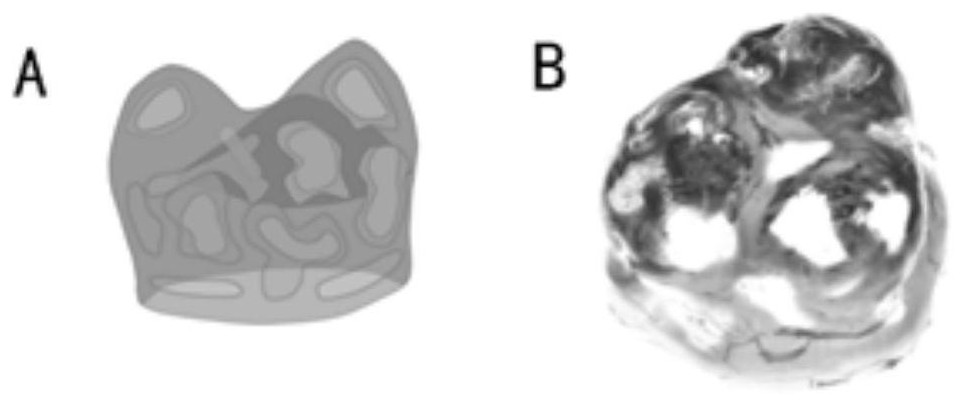

[0077] (1) The CT images of heart valves obtained in actual cases (such as figure 1 shown in A) and convert it into a fully editable 3D model (such as figure 1 shown in B); further extract features to form a frame model with a fiber structure.

[0078] (2) Use deionized water to prepare the hydrogel skeleton pre-polymerization solution, the proportion is acrylamide (AAm) 29wt%, acrylic acid (AA) 3.1wt%, lithium chloride (LiCl) 4wt%, N,N'- Methylbisacrylamide (MBAA) 0.116wt%, TPO modified photoinitiator 0.1wt% and tartrazine photoinhibitor 0.78×10 -4 g / mL.

[0079] (3) The above-mentioned pre-polymerization solution was mixed at a speed of 2000 rpm using a planetary mixer, and after removing air bubbles for 2 minutes, it was poured into a light-curing 3D printer. Here, we use an ENCA printer with a UV light intensity of 3.51mW / cm2. Import ...

Embodiment 2

[0086] This embodiment provides a kind of anti-fatigue all-hydrogel artificial heart valve, and its preparation method is as follows:

[0087] (1) Same as embodiment 1.

[0088] (2) Use deionized water to prepare the hydrogel skeleton pre-polymerization solution, the proportion is polyethylene glycol diacrylate (M-PEG, molecular weight 10000) 30wt%, acrylic acid (AA) 3.1wt%, polyethylene glycol diacrylate Acrylate (PEGDA, molecular weight 1000) 0.15 wt%, α-ketoglutaric acid 0.5 wt%.

[0089] (3) The above-mentioned pre-polymerization solution was mixed at a speed of 1000 rpm using a planetary mixer and debubbled for 4 minutes, and then poured into a light-curing 3D printer. Here, we use ENCA printer, the UV light intensity is 3.51mW / cm 2 . Import the model file to be printed obtained in step (1) into a 3D printer for slicing, with a layer thickness of 50 μm. Using the pre-polymerization solution in step (2) as a printing material, a hydrogel skeleton with this shape is obt...

Embodiment 3

[0095] This embodiment provides a kind of anti-fatigue all-hydrogel artificial heart valve, and its preparation method is as follows:

[0096] (1) Same as embodiment 1.

[0097] (2) Use deionized water to prepare the hydrogel skeleton pre-polymerization liquid, the proportion is 24wt% of acrylamide (AAm), 2.8wt% of acrylic acid (AA), 0.1 of N,N'-methylenebisacrylamide (MBAA) wt%, modified TPO photoinitiator 0.1wt% and curcumin photoinhibitor 0.6×10 -4 g / mL.

[0098] (3) The above-mentioned pre-polymerization solution was mixed at a speed of 3000rpm using a planetary mixer, and after removing air bubbles for 1min, it was poured into a light-curing 3D printer. Here, we use ENCA printer, the UV light intensity is 3.51mW / cm 2 . Import the model file to be printed obtained in step (1) into a 3D printer for slicing, with a layer thickness of 50 μm. Using the pre-polymerization solution in step (2) as a printing material, a hydrogel skeleton with this shape is obtained.

[0099...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com