Mass concrete circulating cooling system

A circulating cooling system and mass concrete technology, applied in the field of concrete pouring, can solve the problems of not considering temperature distribution, concrete damage, low boundary temperature, etc., so as to prevent and limit crack propagation, prevent concrete cracks, and reduce temperature stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

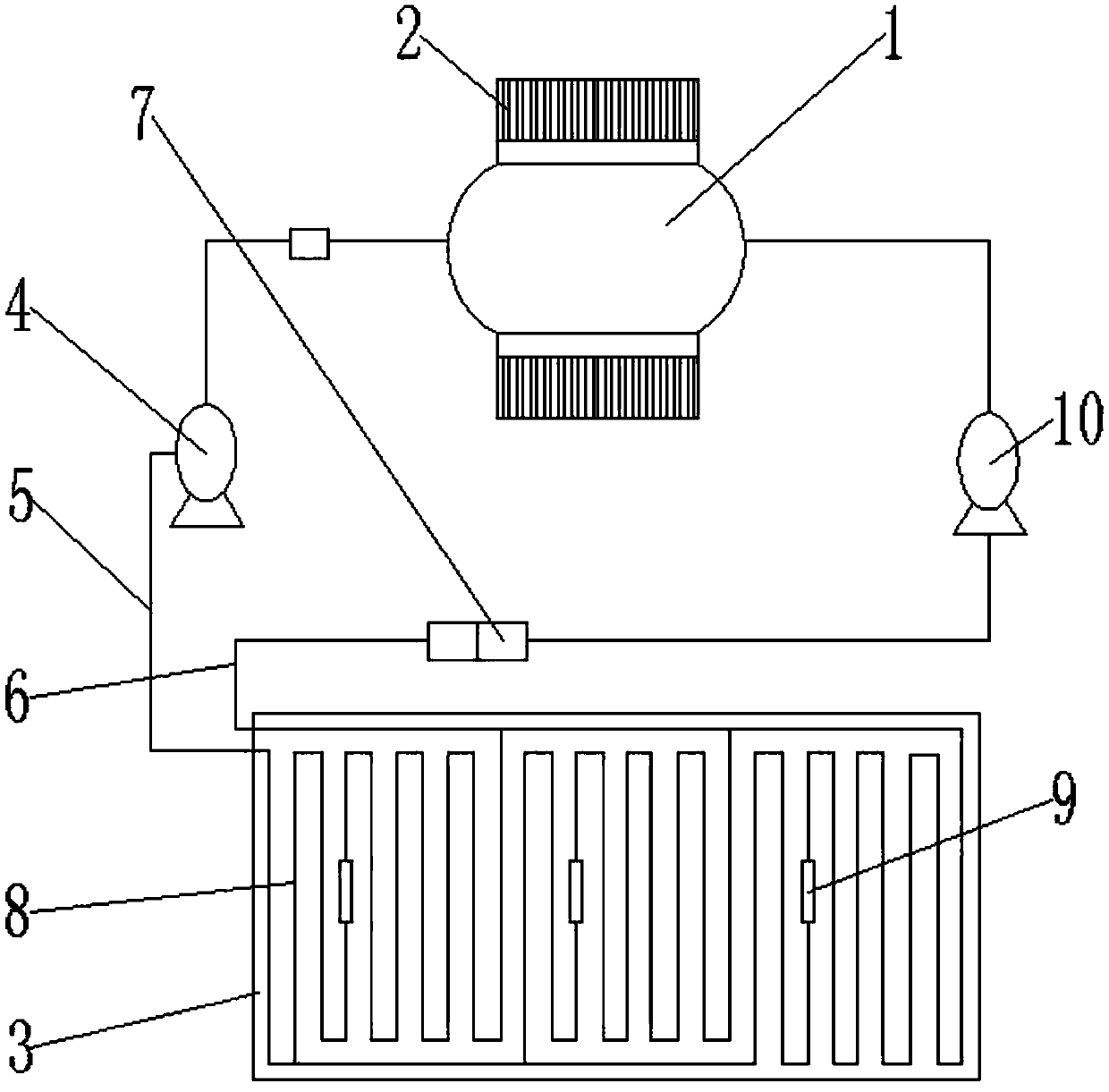

[0020] Such as figure 1 As shown, the large-volume concrete circulating cooling system includes a water storage tank 1, a cooling device 2 and a plurality of cooling water networks 3. The water storage tank 1 is connected to the water inlet end of the water inlet pump 4 through a pipeline, and the drain end of the water inlet pump 4 is connected to the water supply pipeline. 5 connected, the water inlet of each cooling water network 3 is connected with the water supply pipe 5, and the outlet of each cooling water network 3 is connected with the return water pipe 6, and the return water pipe 6 is equipped with a flow limiting valve 7, and the return water pipe 6 It communicates with the water inlet end of the return water pump 10, and the discharge end of the return water pump 10 communicates with the water storage tank 1 through a pipeline. The cooling water in the storage tank 1 is sent into the cooling water network 3 through the water inlet pump 4, and the cooling water net...

Embodiment 2

[0030] Compared with Embodiment 1, this embodiment differs in the temperature and flow rate of the cooling water in the water supply pipe, specifically: the temperature difference between the water temperature in the water supply pipe 5 and the pouring concrete is controlled within 15°C, and the cooling water in the cooling water network 3 The flow rate is controlled at 1m / s, the time from entering the cooling water network 3 to leaving the cooling water network 3 is controlled at 150s, and the difference between the water temperature at the water inlet of the cooling water network 3 and the water temperature at the outlet of the cooling water network 3 Controlled at 3°C. By controlling the temperature and flow rate of the water in the cooling water network 3, the cooling effect of the cooling water network 3 on the poured concrete can be adjusted to avoid cracking of the concrete and ensure the quality of the concrete after solidification.

Embodiment 3

[0032]Compared with Embodiment 1, this embodiment differs in the temperature and flow rate of the cooling water in the water supply pipe, specifically: the temperature difference between the water temperature in the water supply pipe 5 and the pouring concrete is controlled within 20°C, and the cooling water in the cooling water network 3 The flow velocity is controlled at 0.85m / s, the time from entering the cooling water network 3 to leaving the cooling water network 3 is controlled at 180s, and the difference between the water temperature at the water inlet of the cooling water network 3 and the water temperature at the outlet of the cooling water network 3 The value is controlled at 5°C. By controlling the temperature and flow velocity of the water in the cooling water network 3, the cooling effect of the cooling water network 3 on poured concrete can be adjusted to avoid cracking of the concrete and ensure the quality of the concrete after solidification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com