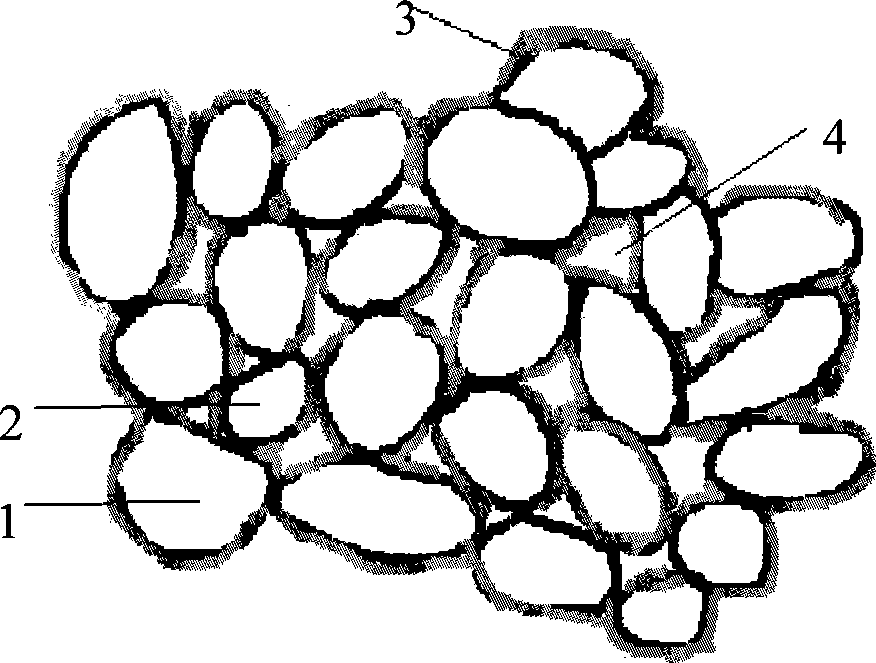

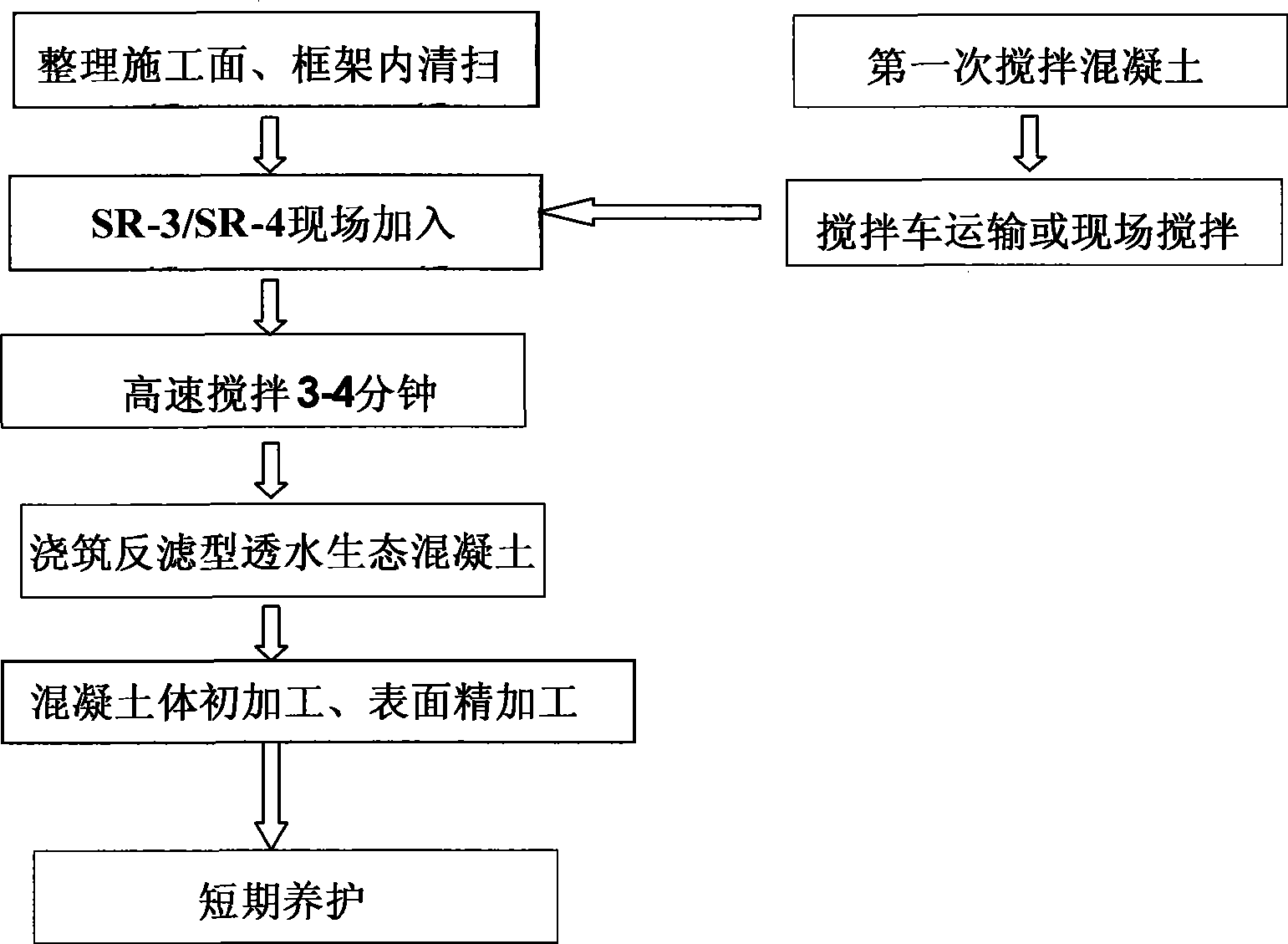

Cast-in-situ invert filter type pervious ecological concrete and method for constructing slope protection thereof

An ecological concrete and cast-in-place technology, applied in the field of ecological concrete, can solve the problems of difficult control of porosity, poor slope protection planting function, low concrete strength, etc., and achieve the effects of improving compressive strength, simplifying construction technology, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Reverse filter type permeable ecological concrete for slope protection

[0051] The particle size distribution of the selected coarse and fine aggregates in Example 1 (reverse filter type permeable ecological concrete for slope protection) is shown in Table 3. The coarse aggregate used is GB / T14685-2001 Class I coarse aggregate, its nominal particle size ranges from 5 to 10mm, the minimum particle size is 2.36mm, and the maximum particle size is 16.0mm.

[0052] Table 3 Particle size distribution of selected coarse and fine aggregates

[0053]

[0054] According to the reverse filter type permeable ecological concrete of the present invention, the standard formula table of each component of embodiment 1 is as shown in table 4.

[0055] Table 4 Standard formulation of filter-type permeable ecological concrete for slope protection

[0056]

[0057] According to the above table, the performance index (measured value) of the reverse filter type permeable e...

Embodiment 2

[0060] Example 2 Reverse filter type permeable ecological concrete for slope protection

[0061] The particle size distribution of the coarse and fine aggregates selected in Example 2 (reverse filter type permeable ecological concrete for slope protection) is shown in Table 6. The coarse aggregate used is the second type of coarse aggregate in GB / T14685-2001, that is, the nominal particle size ranges from 5 to 16.5mm, the minimum particle size is 2.36mm, and the maximum particle size is 19.0mm.

[0062] Table 6 Particle size distribution of selected coarse and fine aggregates

[0063]

[0064]

[0065] According to the anti-filtration type permeable ecological concrete of the present invention, the standard formula of the slope protection anti-filtration type permeable ecological concrete prepared by using the coarse and fine aggregates in the above table is shown in Table 7.

[0066] Table 7 Standard formula table of reverse filter permeable ecological concrete for slo...

Embodiment 3

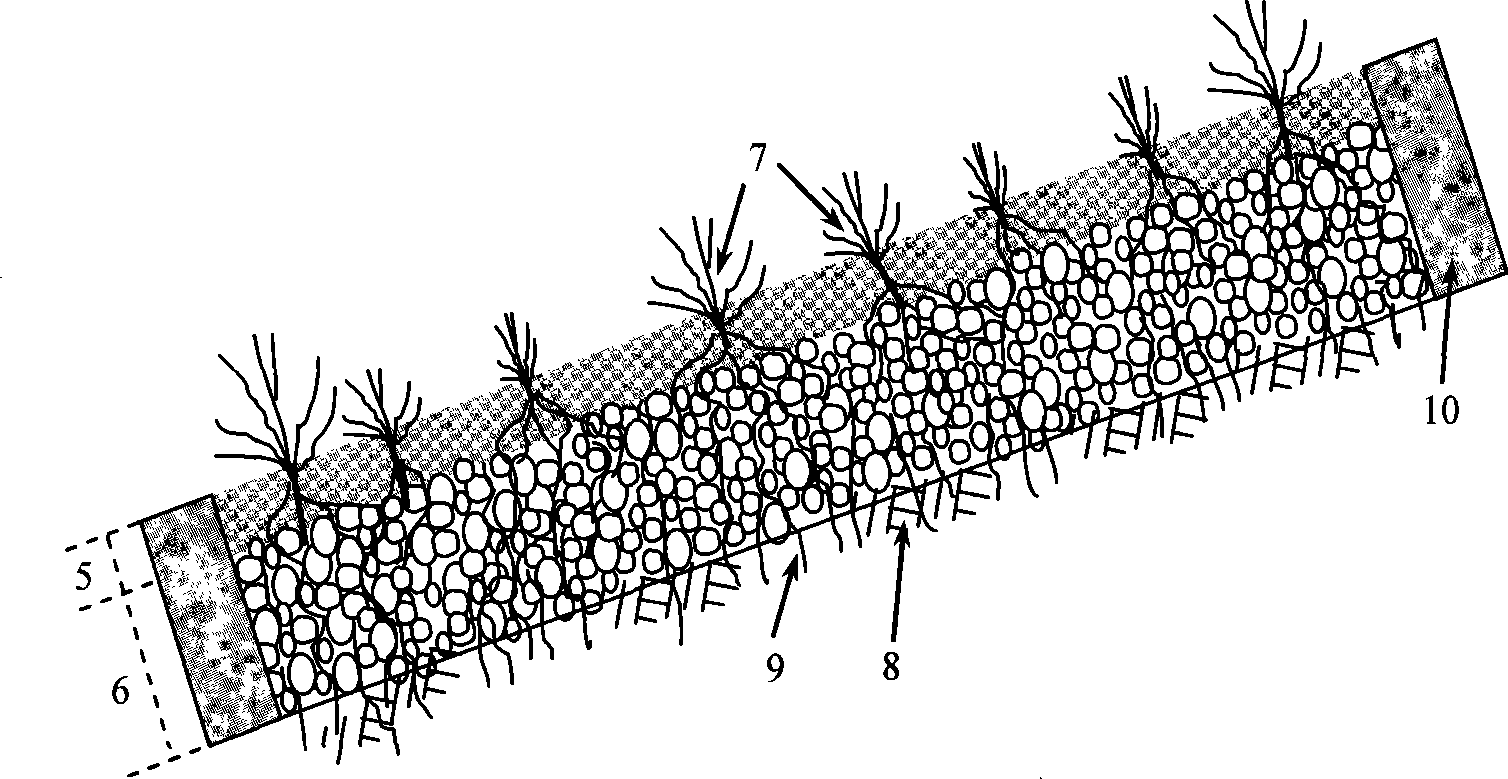

[0071] Example 3 Reverse filter type permeable and vegetative ecological concrete for slope protection

[0072] The particle size distribution of the coarse and fine aggregates selected in Example 3 (reverse filter type permeable and plant-growing ecological concrete for slope protection) is shown in Table 9. The coarse aggregate used is the third type of coarse aggregate in GB / T14685-2001, that is, the nominal particle size ranges from 5 to 20mm, the minimum particle size is 2.36mm, and the maximum particle size is 26.5mm.

[0073] The anti-filter type permeable ecological concrete in this embodiment has a certain vegetation function, so coarse aggregate with a relatively large particle size is selected to expand the aperture of the continuous gap in the anti-filter type permeable ecological concrete so that the roots of the plants can penetrate into the concrete. .

[0074] Table 9 Particle size distribution of selected coarse and fine aggregates

[0075]

[0076]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com