Epoxy resin injecting paste material for maintenance of road engineering and preparation method thereof

An epoxy resin and road engineering technology, which is applied in the field of epoxy resin grouting materials and its preparation, can solve the problems of late traffic opening, strong social response, and large grouting hole diameter, and achieve good foundation reinforcement, excellent mechanical properties, The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

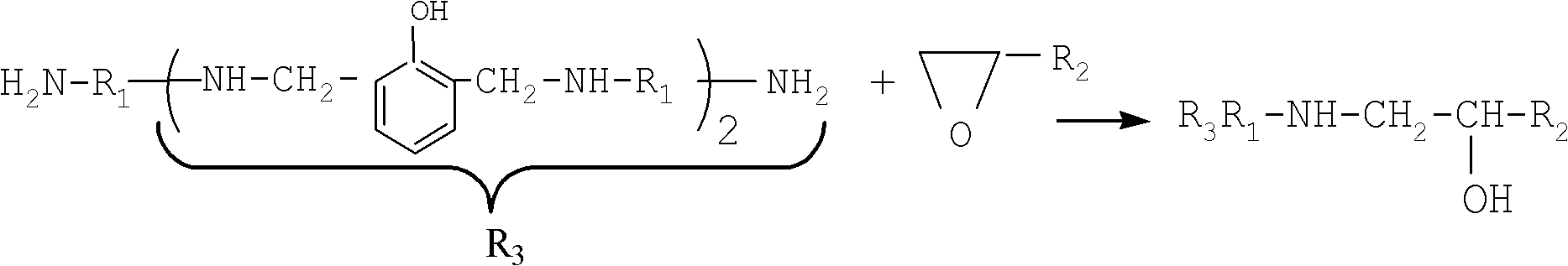

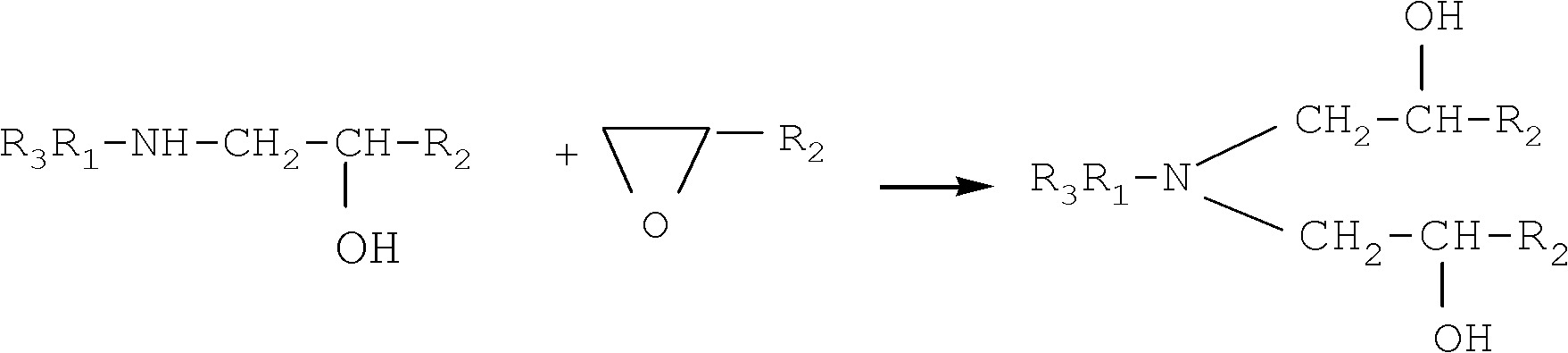

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 (recipe number 1)

[0042] Epoxy component A

parts by weight

Curing agent component B

parts by weight

CYD-128

100

Curing agent T-31

35

AGE

40

DMP-30

0.05

[0043] The preparation method comprises the following steps:

[0044] 1), the preparation of epoxy component A: mix bisphenol A epoxy resin and reactive diluent AGE according to the above ratio, stir at room temperature for 5 minutes, and mix well to obtain epoxy component A;

[0045] 2) Preparation of curing agent component B: Mix the modified aliphatic polyamine curing agent T-31 with 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30) according to the above ratio, Stir at room temperature for 5 minutes, and mix well to obtain curing agent component B;

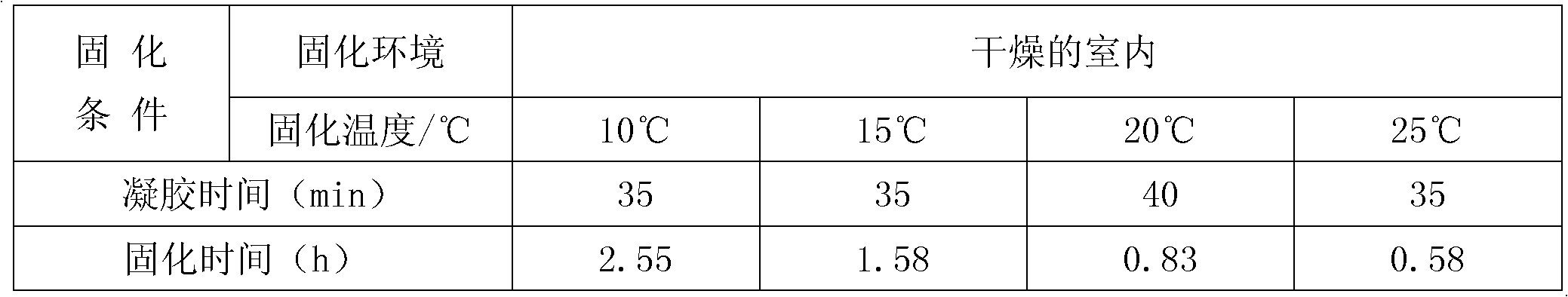

[0046] 3) When in use, mix the epoxy component A and the curing agent component B at room temperature, and stir for 8 minutes to obtain the grouting material of the present invention. ...

Embodiment 2

[0048] Embodiment 2 (recipe number 2)

[0049] Epoxy component A

parts by weight

B component

parts by weight

CYD-128

100

Curing agent T-31

45

AGE

40

DMP-30

0.05

[0050] The preparation method is the same as in Example 1.

[0051] In this embodiment, the epoxy resin grouting material gels in 55 minutes at 10° C., solidifies in 1.65 hours, gels in 25 minutes at 20° C., solidifies in 1 hour, and is firmly bonded on a wet surface.

Embodiment 3

[0052] Embodiment 3 (recipe number 3)

[0053] Epoxy component A

parts by weight

Curing agent component B

parts by weight

CYD-128

100

Curing agent 593

50

AGE

40

DMP-30

0.10

[0054] The preparation method is the same as in Example 1.

[0055] In this embodiment, the epoxy resin grouting material gels in 81 minutes at 10° C., solidifies in 1.92 hours, gels in 42 minutes at 20° C., solidifies in 1.38 hours, and is firmly bonded on a wet surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com