A high-pressure-resistant water-permeable porous material and a preparation method thereof

A technology of porous materials and water permeability, applied in the field of porous materials, can solve the problems of poor high pressure resistance, difficult control of porosity, difficult molding mold materials, etc., to maintain air permeability, water permeability and strength, improve fluidity and dispersibility , the effect of high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: the silanization wet treatment of inorganic filler

[0052] First, place various inorganic fillers for experiments in an oven at 120°C for 5 hours to keep warm and dry, take 1000g each after cooling, pour them into a 5L three-necked flask equipped with a reflux cooling device, and then add 1000g of 5wt% 3-formazol Acryloyloxypropyltrimethoxysilane (KH570) No. 120 solvent gasoline solution and 0.3g of dibutyltin dilaurate, heated to 60 ° C under reflux and stirred for 8 hours, cooled to room temperature, then filtered, and the powder was naturally Drying to obtain the surface-treated inorganic filler of silane KH570; the inorganic filler is aluminum oxide, magnesium oxide, calcium hydroxide, magnesium hydroxide, aluminum hydroxide, titanium dioxide, magnesium carbonate, lithium magnesium silicate, magnesium aluminum silicate , borax, dolomite, gypsum, barite, talc, kaolin, wollastonite or glass powder.

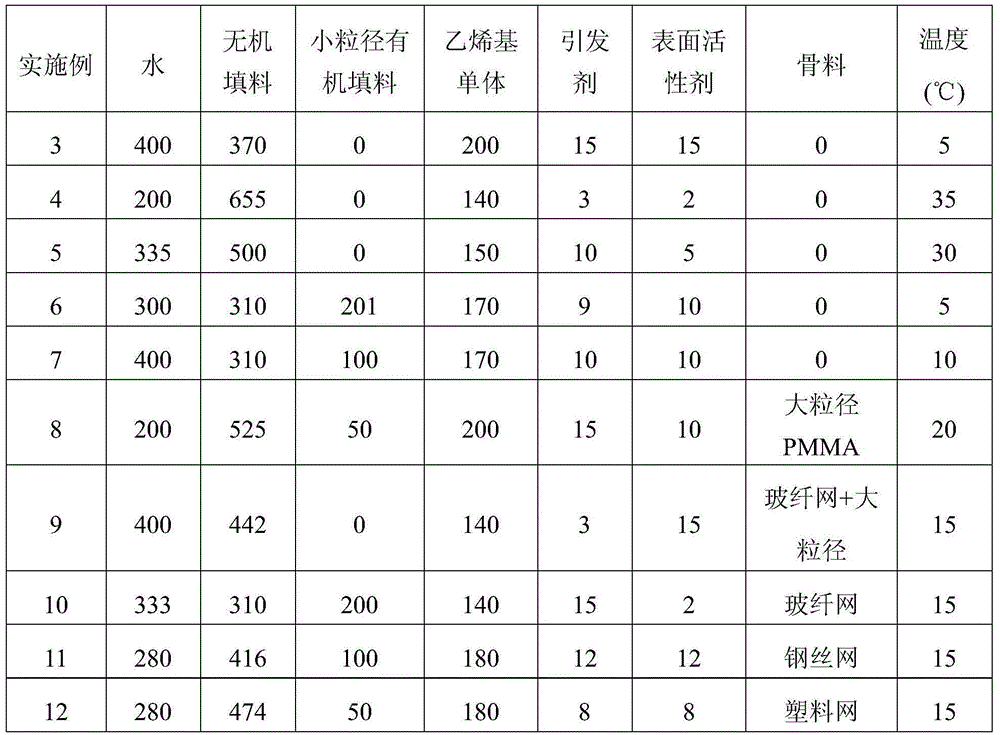

[0053] The inorganic filler surface-treated with vin...

Embodiment 2

[0054] Example 2: Wet treatment of silanization of organic fillers with small particle size

[0055] In a 5L three-neck flask equipped with a reflux cooling device, add 1000g of small particle size organic filler, and then add 1000g of 5wt% 3-methacryloxypropyltrimethoxysilane (KH570) No. 120 solvent gasoline solution and 0.3g of dibutyltin dilaurate, heated to 60°C under reflux and stirred for 8 hours, cooled to room temperature, then filtered, and the powder was naturally dried to obtain a small particle size organic filler treated with silane KH570 surface; the organic filler It is polymethyl methacrylate PMMA, polyoxymethylene POM or polycarbonate PC.

[0056] The small-particle size organic fillers treated with vinyltrimethoxysilane are also carried out according to the above method.

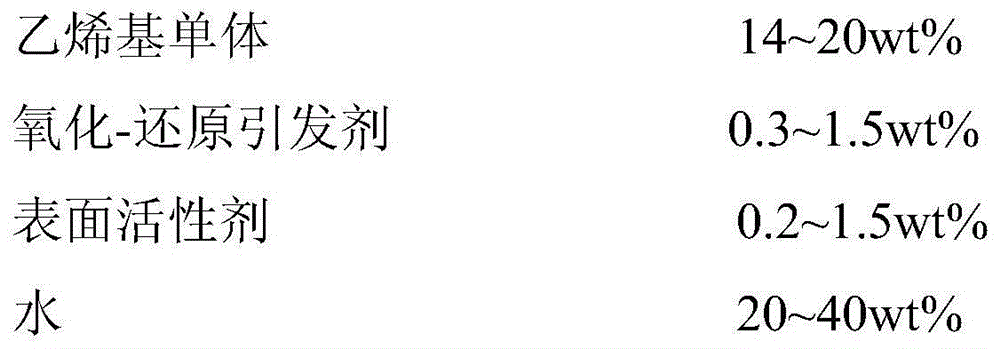

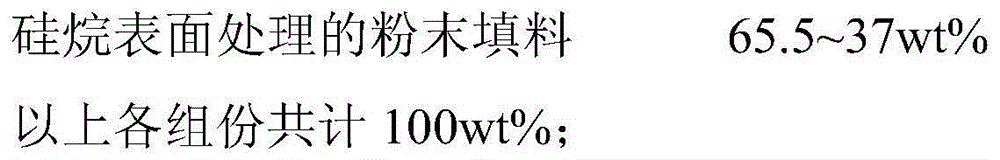

[0057] Examples 3-12 were carried out according to the formula and curing temperature in Table 1.

[0058] Table 1: Example composition (1000 parts in total (except aggregate)):

[0059]...

Embodiment 3

[0061] At room temperature at 5°C, mix 400g of water, 300g of silane KH570 surface-treated magnesium oxide (average particle size 50μm) and KH570 surface-treated aluminum hydroxide (average particle size 3μm) 70g (stirring speed is 200 rpm, stirring The time is 10min) to obtain the water-containing component; add 100g styrene, 50g ethylene glycol maleate, 50g methyl acrylate, 10g dilauroyl peroxide (LPO), 5g N,N-di Methylaniline (DMA) and 15g polyether L64 (polyoxyethylene content 40wt%), at 5 ℃, stir and mix evenly (stirring speed is 200 rpm, stirring time is 5min), to obtain the premixed liquid (oil-containing group minute); then, under rapid stirring (stirring speed is 1000 rev / min), add the water-containing component into the container containing the premix liquid, and stir evenly (stirring time is 2min) to obtain a mixed slurry; after mixing evenly, quickly Pour the mixed slurry into the corresponding hollow mold, let it stand at room temperature for curing at 5°C, observ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com