Low-moisture ceramic slurry, and application thereof in lithium ion battery diaphragm

A ceramic slurry, low-moisture technology, used in battery pack parts, circuits, electrical components, etc., can solve the problems of many operation steps, difficult control, and difficulty in mass production, and achieve improved safety performance and excellent specific surface area. , the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

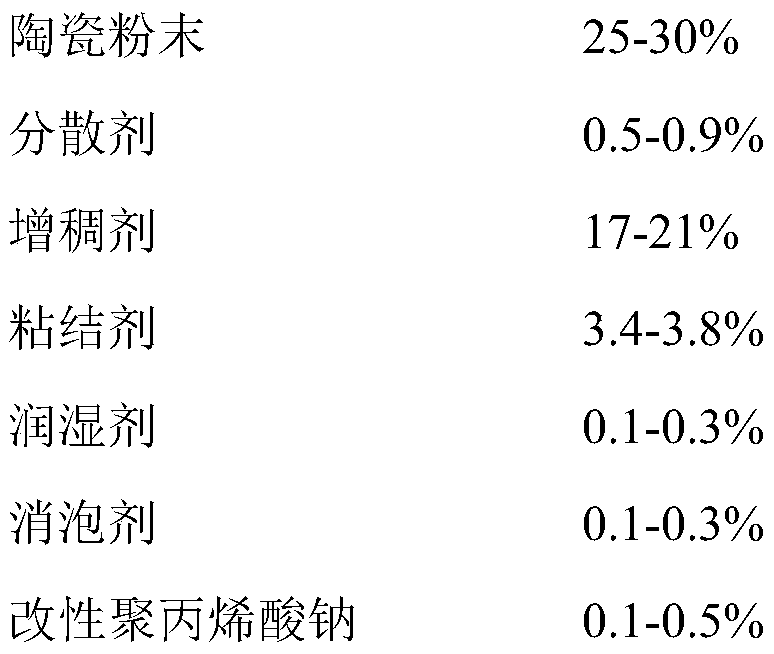

[0034] A kind of low moisture ceramic slurry, comprises the raw material of following percentage by weight:

[0035]

[0036] The ceramic slurry is prepared through the following steps:

[0037] 1) According to the weight ratio, disperse the ceramic powder, modified sodium polyacrylate and dispersant in deionized water A and add to the stirring equipment, heat to 20°C and stir for 80 minutes at the rotation rate of 1000r / min and the revolution rate of 25r / min to Stir well to obtain mixture A, set aside;

[0038] 2) Add the thickener to the mixture A obtained in step 1), and keep stirring at a rotation rate of 1000r / min and a revolution rate of 25r / min at 20°C for 20min until a stable dispersion system B is obtained, and set aside;

[0039] 3) Add the binder, wetting agent and polyvinyl alcohol into the dispersion system B at intervals of 25 minutes, the rotation rate of the binder and the wetting agent is 100r / min, and the revolution rate is 25r / min when stirring. After a...

Embodiment 2

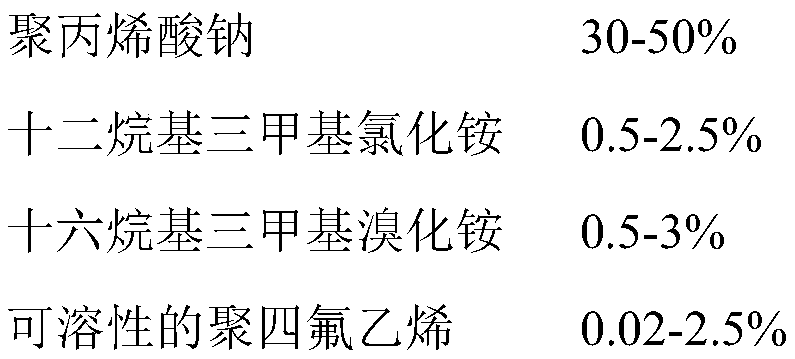

[0053] A kind of low moisture ceramic slurry, comprises the raw material of following percentage by weight:

[0054]

[0055] The ceramic slurry is prepared through the following steps:

[0056] 1) According to the weight ratio, disperse the ceramic powder, modified sodium polyacrylate and dispersant into deionized water A and add to the stirring equipment, heat to 23°C and stir for 90 minutes at the rotation rate of 1100r / min and the revolution rate of 28r / min to Stir well to obtain mixture A, set aside;

[0057] 2) Add the thickener to the mixture A obtained in step 1), and keep stirring for 25 minutes at a rotation rate of 1100r / min and a revolution rate of 28r / min at 23°C until a stable dispersion system B is obtained, and set aside;

[0058] 3) The binder, wetting agent and polyvinyl alcohol were added to the dispersion system B at intervals of 28 minutes. The rotation rate of the binder and wetting agent was 110 r / min and the revolution rate was 28 r / min when stirrin...

Embodiment 3

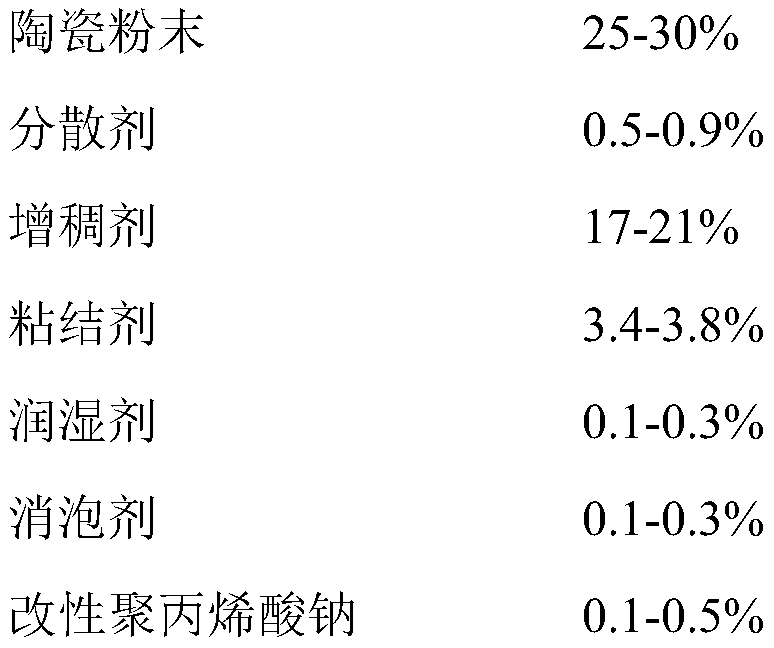

[0072] A kind of low moisture ceramic slurry, comprises the raw material of following percentage by weight:

[0073]

[0074] The ceramic slurry is prepared through the following steps:

[0075] 1) According to the weight ratio, disperse the ceramic powder, modified sodium polyacrylate and dispersant into deionized water A and add to the stirring equipment, heat to 25°C and stir for 100min at the rotation rate of 1200r / min and the revolution rate of 30r / min to Stir well to obtain mixture A, set aside;

[0076] 2) Add the thickener to the mixture A obtained in step 1), and keep stirring at a rotation rate of 1200r / min and a revolution rate of 30r / min at 25°C for 30min until a stable dispersion system B is obtained, and set aside;

[0077] 3) Add the binder, wetting agent and polyvinyl alcohol into the dispersion system B at intervals of 30 minutes, the rotation rate of the binder and the wetting agent is 120r / min and the revolution rate is 30r / min when stirring, After addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com