Coal-doped oil-making furnace slag mortar and preparation method thereof

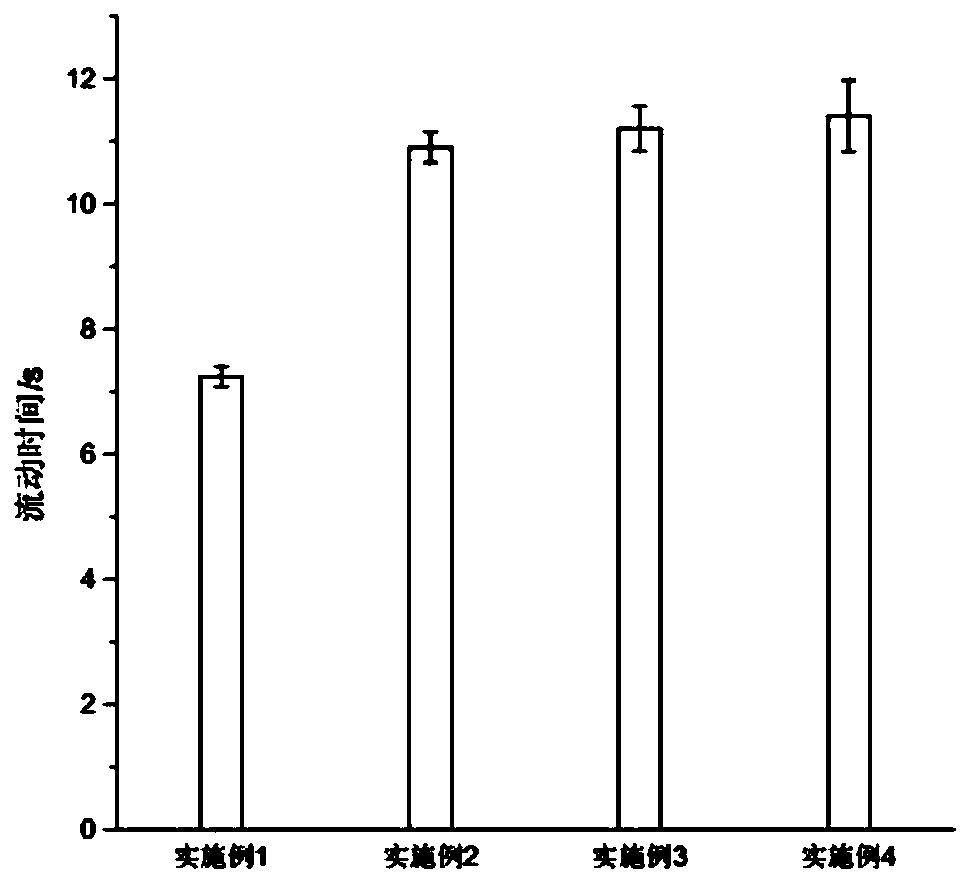

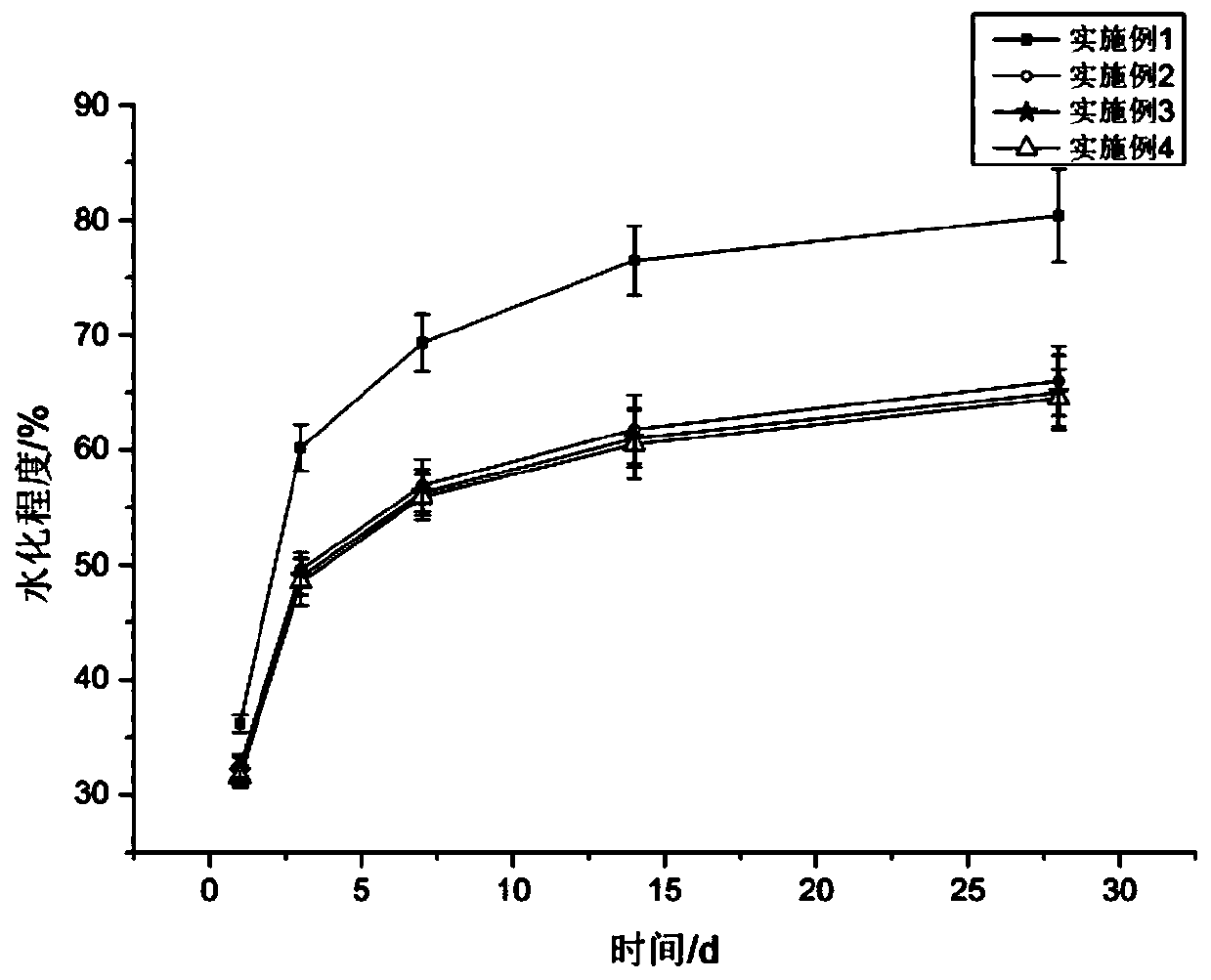

A coal-to-oil and slag technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve land, water source pollution, living environment hazards, air pollution, etc., to improve the degree of hydration, The effect of reducing wrapping and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A surface treatment method for coal-to-oil slag, comprising:

[0060] Test raw material: Coal-to-oil slag is gasification slag from coal indirect liquefaction to oil, which is screened through a 1.16mm sieve.

[0061] 1) Take 1 kg of coal-to-oil slag and add it to a ball mill for grinding, and pass through a 200-mesh sieve;

[0062] 2) Prepare 1L of 4.3g / L trimethylpyruvate solution, add it to the pulverized coal-to-oil slag, mix well, and let stand for 5 minutes;

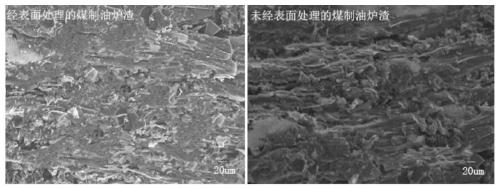

[0063] 3) Add dodecyl glucoside with a final concentration of 16g / L, heat to 62°C, stir at a constant temperature for 30 minutes, wash with clean water for 3 times, dry, put into a ball mill for coarse grinding, and pass through a 60-mesh sieve to obtain surface treatment coal-to-oil slag. The scanning electron micrographs of coal-to-oil slag without surface treatment and after surface treatment are shown in figure 1 . Depend on figure 1 It can be seen that, compared with the coal-to-oil slag without su...

Embodiment 2

[0070] No trimethylpyruvate was added to the surface treatment of the coal-to-oil slag, and the rest was exactly the same as in Example 1.

Embodiment 3

[0072] When the coal-to-oil slag is surface treated, no dodecyl glucoside is added, and the rest is exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com