Priming coat type acrylic acid ester conductive adhesive and preparation method thereof

An acrylate and adhesive technology, used in conductive adhesives, adhesives, polyurea/polyurethane adhesives, etc., can solve the problems of damaging the mechanical properties of the system, affecting the sizing performance, increasing the viscosity, etc., to promote dispersion and operation. Simple and effective in reducing viscosity of resin system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A kind of preparation method of primer type acrylate conductive adhesive, the steps are:

[0042] Preparation of the main ingredient:

[0043] (1) Mix 40~65 parts of acrylate monomer containing at least one vinyl group, 10~30 parts of vinyl-terminated prepolymer and 0.1~3 parts of stabilizer, control the temperature below 35°C, and stir evenly;

[0044] (2) Then add 5~30 parts of conductive filler to the resin matrix formed in step 1), stir well, and control the temperature of the system not to exceed 35°C;

[0045] (3) Then add 0.5~3 parts of peroxide initiator, 0.1~3 parts of curing accelerator, 1~5 parts of anti-settling agent in sequence, control the temperature of the system below 35°C, stir well and then defoam under vacuum conditions, Discharge and store in cold storage at 2-8°C.

[0046] Preparation of primer:

[0047] Mix 30~35 parts of activator and 65~70 parts of solvent evenly under nitrogen atmosphere, discharge the material, fill it with nitrogen and seal...

Embodiment 1

[0050] A kind of primer type acrylate conductive adhesive, its formula is composed as follows:

[0051] Main ingredient:

[0052] Hydroxyethyl methacrylate 60 %wt

[0053] Methyl urethane acrylate 15%wt

[0054] p-Benzoquinone 0.3%wt

[0055] EDTA tetrasodium salt 0.1%wt

[0056] Graphene 4.7%wt

[0057] Special Conductive Carbon Black 14%wt

[0058] O-benzoylsulfonimide 1%wt

[0059] Cumene hydroperoxide 1.4%wt

[0060] Fumed silica 3.5%wt

[0061] Primer:

[0062] Ethyl acetate 54 %wt

[0063] Isopropanol 15.99%wt

[0064] Aldehyde amine condensation product 30%wt

[0065] Copper acetylacetonate 0.01%wt

[0066] Performance Testing:

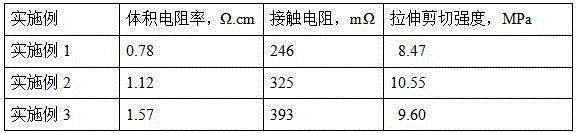

[0067] 1. Volume resistivity: test according to QJ1523-1988, apply glue on one side of the glass slide, put copper foil on both ends, apply primer on the other glass slide, overlap and press, and test the resistance value after standing at room temperature for 24 hours And calculate the volume resistivity. Make 5 groups of parall...

Embodiment 2

[0071] A kind of primer type acrylate conductive adhesive, its formula is composed as follows:

[0072] Main ingredient:

[0073] Hydroxypropyl methacrylate 59 %wt

[0074] Methepoxy acrylate 25%wt

[0075] 1,4-Hydroquinone 0.4%wt

[0076] EDTA tetrasodium salt 0.1%wt

[0077] Multi-walled carbon nanotubes 8.5%wt

[0078] O-benzoylsulfonimide 0.5%wt

[0079] Acetylphenylhydrazine 0.5%wt

[0080] Cumene hydroperoxide 1%wt

[0081] Bentonite 5%wt

[0082] Primer, performance test are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com