Room curing fluoro rubber adhesive and preparation method

A room temperature curing, fluorine rubber raw rubber technology, applied in the direction of adhesives, etc., can solve the problems of low initial adhesion, low bonding strength, slow curing speed, etc., achieve high initial adhesion, low cost, and improve initial adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

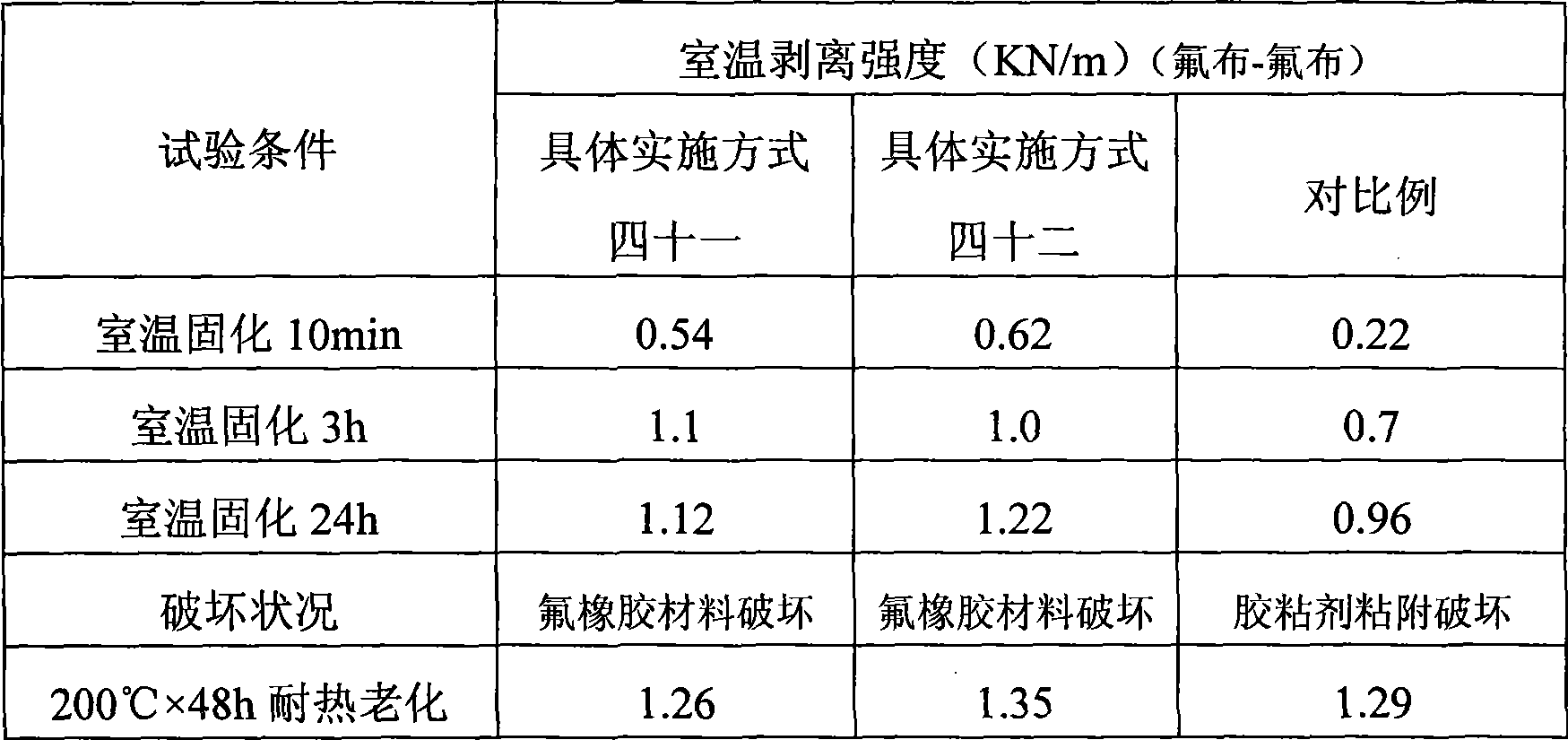

Examples

specific Embodiment approach 1

[0018] Embodiment 1: In this embodiment, the room temperature curing fluororubber adhesive is composed of component A and component B, wherein component A is composed of 100 parts of fluororubber raw rubber, 5 to 15 parts of acid absorbing agent, 5-20 parts of reinforcing filler, 2-10 parts of vulcanizing agent, 10-30 parts of epoxy resin, 5-20 parts of polyurethane emulsion, 300-400 parts of organic solvent; component B is composed of 1-5 parts by weight It is made of 1 part of organic amine curing agent, 1-5 parts of silane coupling agent and 10-50 parts of organic solvent.

[0019] In this embodiment, before sizing, component A and component B are uniformly mixed in a weight ratio of 100:5-15.

specific Embodiment approach 2

[0020] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: Group A consists of 100 parts of fluororubber raw rubber, 8 to 12 parts of acid absorbing agent, 8 to 15 parts of reinforcing filler, 5 to 10 parts by weight. It is made of 8 parts of vulcanizing agent, 12-25 parts of epoxy resin, 8-16 parts of polyurethane emulsion and 320-380 parts of organic solvent.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one is that: Group A consists of 100 parts of fluororubber raw rubber, 10 parts of acid absorbing agent, 12 parts of reinforcing filler, 6 parts of vulcanizing agent, 15 parts of Part epoxy resin, 12 parts polyurethane emulsion and 350 parts organic solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com