Multi-purpose modified epoxy resin adhesive

An epoxy resin, multi-purpose technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of repairing glue stickiness, excessive filler, insufficient material toughness, etc., to achieve good toughness and impact resistance Ability, high bond strength, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] A multifunctional modified epoxy resin repair glue, which is made of the following materials according to the mass ratio:

[0018] A component:

[0019] Main agent: bisphenol A type epoxy resin E-51 100 parts

[0020] Toughening agent: Qishi toughening agent 14 parts

[0021] Reactive diluent: 6 parts of benzyl glycidyl ether

[0022] Thixotropic agent: white carbon black (fumed silica) 3 parts

[0023] Filler: 400 mesh silica powder 120 parts

[0024] Component B:

[0025] Curing agent: compound curing agent 35 parts

[0026] Accelerator: DMP-30 1.5 parts

[0027] Coupling agent: KH-550 2 parts

[0028] Thixotropic agent: white carbon black (fumed silica) 2 parts

[0029] Active filler: 40 parts of active silica powder

[0030] The mass ratio of component A and component B is 3:1

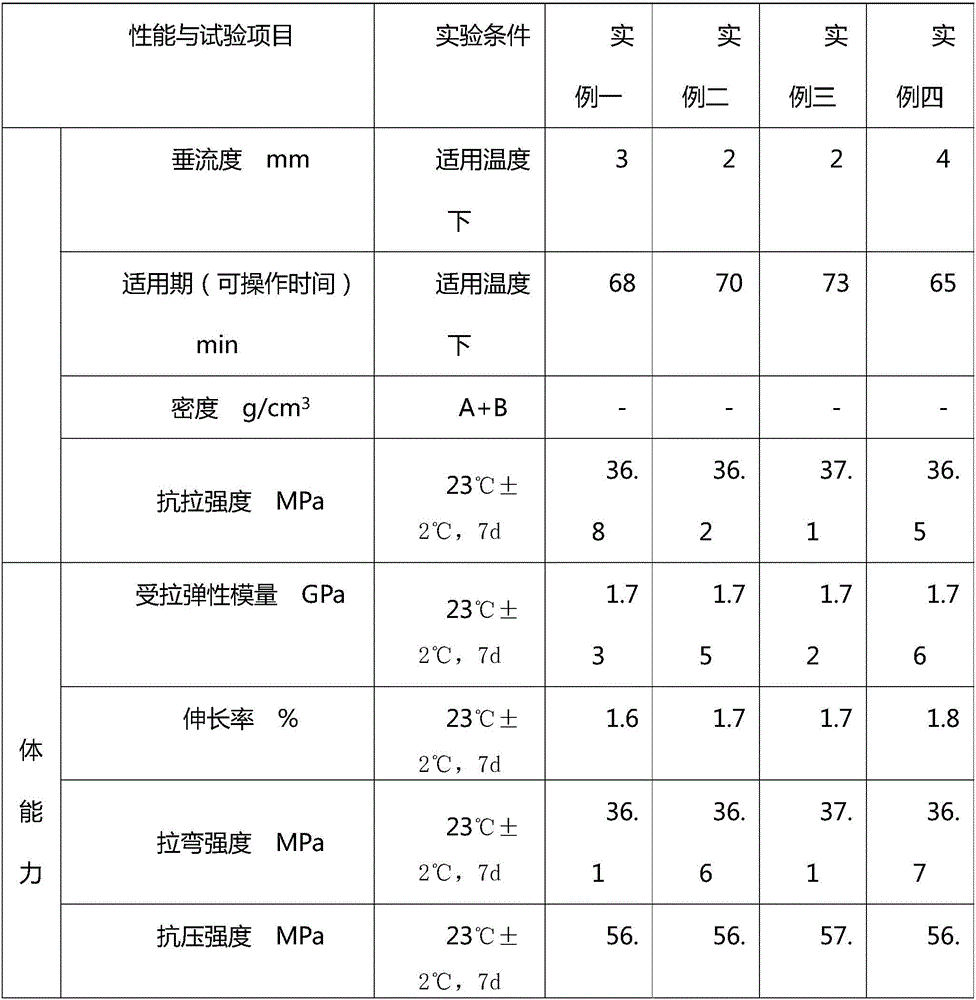

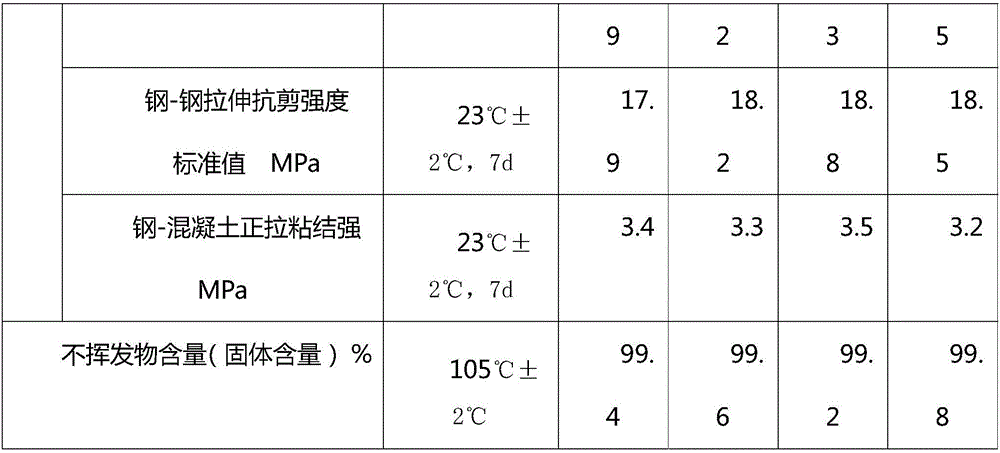

[0031] Implementation results: product testing results are shown in Table 1

example 2

[0033] A multifunctional modified epoxy resin repair glue, which is made of the following materials according to the mass ratio:

[0034] A component:

[0035] Main agent: bisphenol A type epoxy resin E-51 100 parts

[0036] Toughening agent: Qishi toughening agent 13 parts

[0037] Reactive diluent: 7 parts of benzyl glycidyl ether

[0038] Thixotropic agent: white carbon black (fumed silica) 3 parts

[0039] Filler: 400 mesh silica powder 120 parts

[0040] Component B:

[0041] Curing agent: compound curing agent 35 parts

[0042] Accelerator: DMP-30 2 parts

[0043] Coupling agent: KH-550 2 parts

[0044] Thixotropic agent: white carbon black (fumed silica) 2 parts

[0045] Active filler: 40 parts of active silica powder

[0046] The mass ratio of component A and component B is 3:1

[0047] Implementation results: product testing results are shown in Table 1

example 3

[0049] A multifunctional modified epoxy resin repair glue, which is made of the following materials according to the mass ratio:

[0050] A component:

[0051] Main agent: bisphenol A type epoxy resin E-51 100 parts

[0052] Toughening agent: Qishi toughening agent 12 parts

[0053] Reactive diluent: 8 parts of benzyl glycidyl ether

[0054] Thixotropic agent: 2.5 parts of white carbon black (fumed silica)

[0055] Filler: 400 mesh silica powder 120 parts

[0056] Component B:

[0057] Curing agent: compound curing agent 40 parts

[0058]Accelerator: DMP-30 1.5 parts

[0059] Coupling agent: KH-550 2 parts

[0060] Thixotropic agent: white carbon black (fumed silica) 2 parts

[0061] Active filler: 40 parts of active silica powder

[0062] The mass ratio of component A and component B is 3:1

[0063] Implementation results: product testing results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com