A kind of ultra-low hardness polyurethane potting glue and its preparation and application

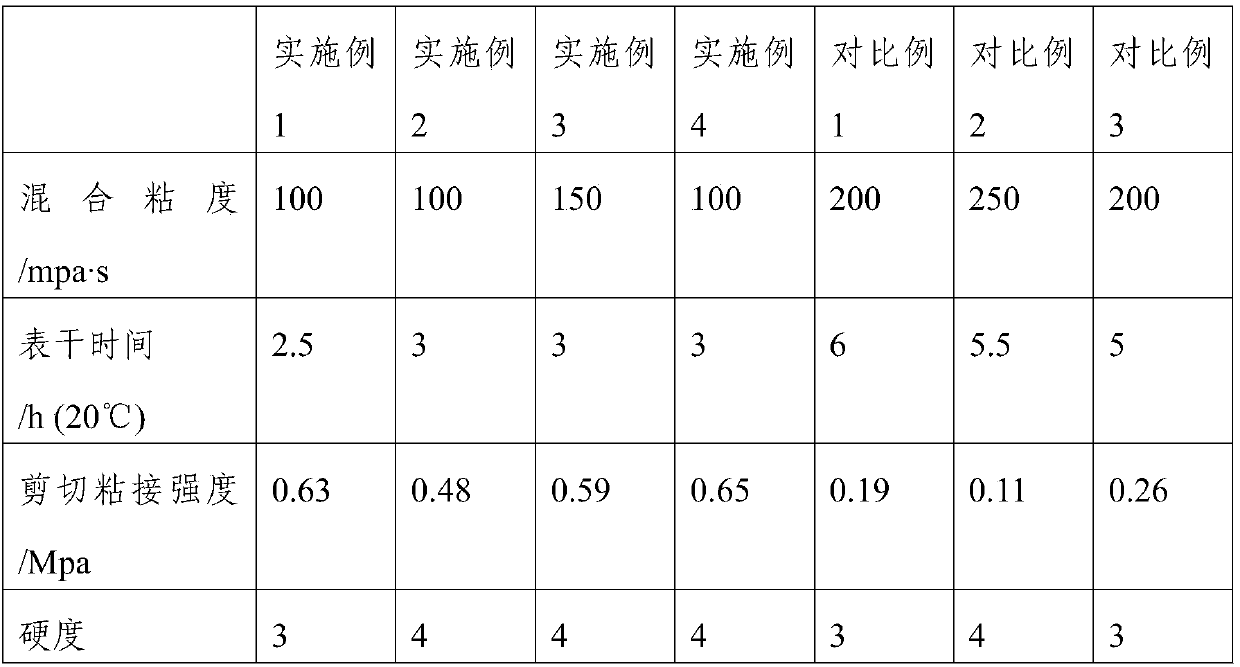

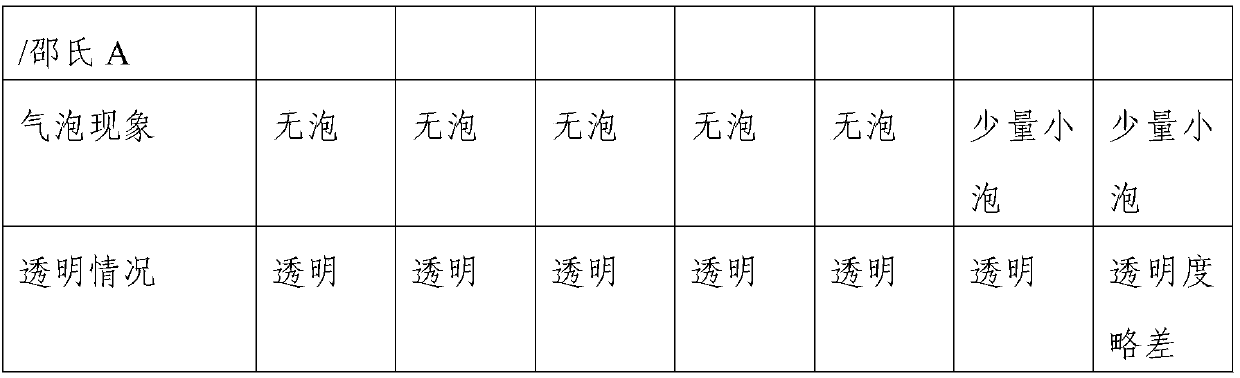

A technology of potting glue and polyurethane, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of long curing time and low application efficiency, and achieve excellent electronic insulation performance, Less air bubbles and low mixing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of ultra-low hardness polyurethane potting glue

[0027] This embodiment provides an ultra-low hardness polyurethane potting compound, which includes the following components:

[0028] The component A is prepared from the following components by weight: 96.9 parts of castor oil, 0.5 parts of composite anti-yellowing agent, 0.4 parts of catalyst DY-5300, 0.5 parts of catalyst DY-20, and 0.2 parts of defoamer BYK-1794 parts, coupling agent KH-560 1.5 parts;

[0029] The component B is prepared from the following components by weight: 70 parts of plasticizer DOP, 20 parts of SUP2020, and 10 parts of HB 8960B.

[0030] Concrete preparation method comprises the following steps:

[0031] Preparation of component A: Add castor oil into the reaction kettle, vacuumize at 100°C for 3.5 hours to dehydrate to make the water content <0.05%, lower the temperature to 30°C, add 0.4 parts of catalyst DY-5300, 0.5 parts of DY-20, 0.2 parts of foaming agent BYK-1794...

Embodiment 2

[0033] Embodiment 2 A kind of ultra-low hardness polyurethane potting glue

[0034] This embodiment provides an ultra-low hardness polyurethane potting compound, which includes the following components:

[0035] The component A is prepared from the following components by weight: 96.4 parts of castor oil, 0.5 parts of composite anti-yellowing agent, 0.6 parts of catalyst DY-5350, 0.3 parts of DY-20, and 0.2 parts of defoamer BYK-1794 , 2.0 parts of coupling agent KH-560;

[0036] The component B is prepared from the following components by weight: plasticizer DOP 70 parts, Sup2020 24 parts, Sup 24396 parts.

[0037] Concrete preparation method comprises the following steps:

[0038] Component A: Add 96.4 parts of castor oil into the reaction kettle, vacuumize at 100°C for 3 hours to dehydrate to make the water content <0.05%, cool down to 30°C, add 0.6 parts of catalyst DY-5350, 0.3 parts of DY-20, 0.2 parts of foam agent BYK-1794, 0.5 parts of compound anti-yellowing agent...

Embodiment 3

[0040] Embodiment 3 A kind of ultra-low hardness polyurethane potting glue

[0041] This embodiment provides an ultra-low hardness polyurethane potting compound, which includes the following components:

[0042] The component A is prepared from the following components by weight: 95.9 parts of castor oil, 0.5 parts of compound anti-yellowing agent, 0.4 parts of catalyst 1619, 0.2 parts of defoamer BYK-066N, and 1.0 parts of coupling agent KH-792 Parts, plasticizer DOP 2 parts,;

[0043] The component B is prepared from the following components in parts by weight: plasticizer DOP 68 parts, Sup2511 32 parts.

[0044] Concrete preparation method comprises the following steps:

[0045] Component A: Add 95.9 parts of castor oil and 2 parts of DOP into the reaction kettle, vacuumize at 100°C for 3.5 hours to dehydrate, make the water content <0.05%, cool down to 25°C, add 0.4 parts of catalyst 1619, defoamer BYK 0.2 part of -066N, 0.5 part of compound anti-yellowing agent, 1.0 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com