Corrosion-resisting wear-resisting powder coating for metal

A powder coating and metal anti-corrosion technology, applied in powder coatings, polyamide coatings, coatings, etc., can solve the problems of high cost, limited coating application, complex synthesis process, etc., achieving a small friction coefficient, outstanding elasticity and flexibility, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

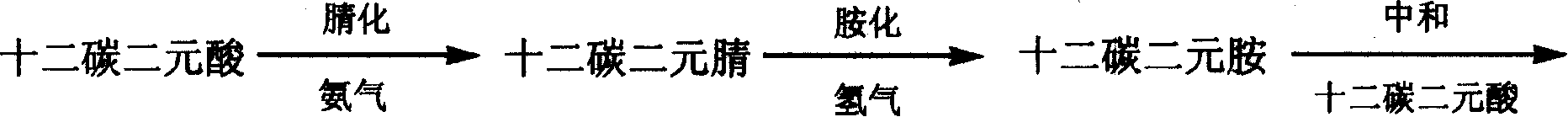

Method used

Image

Examples

Embodiment 1

[0026] Ferment nylon-1212, 10g TiO with 100g petroleum 2 , 0.8g polyacrylate, 0.3g antioxidant 1010, 0.2g antioxidant 168 were prepared into a powder coating. The coating was applied on a tableware rack, the surface of the coating was smooth and clean, and the steel bar of the tableware rack was bent 360 degrees, and no cracks and coating peeling were seen on the base surface; soaked in 9% sodium chloride aqueous solution at 40°C No rust was found on the surface of the coating for 288 hours.

Embodiment 2

[0028] Prepare powder coating with 200g of petroleum fermented nylon-1212, 15g of epoxy resin E-12, and 10g of graphite. The coating was applied to a mechanical sliding bearing. Under the condition of a small amount of oil lubrication, the bearing had been running continuously for 2 years without falling off the surface and the wear was 0.04mm.

Embodiment 3

[0030] Prepare a powder coating with 100g petroleum fermented nylon-1212, 5g epoxy resin E-12, 0.1g bis-nitrile amine, 5g graphite, 10g aluminum oxide, and 1g polyvinyl butyral. The coating is applied to the inner wall of a ball mill roller, and the service life of the original equipment without powder coating is increased by 3 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com