Method for mounting main unit with resilient support

A technology of elastic support and installation method, applied in the directions of transportation and packaging, propulsion engine, ship propulsion, etc., can solve the problems of large vibration amplitude of the hull, affecting vibration control, and high noise of the ship, so as to shorten the installation period, reduce vibration and noise Weakening and progressing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific application of the host installation method with elastic support will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention should not be limited by this.

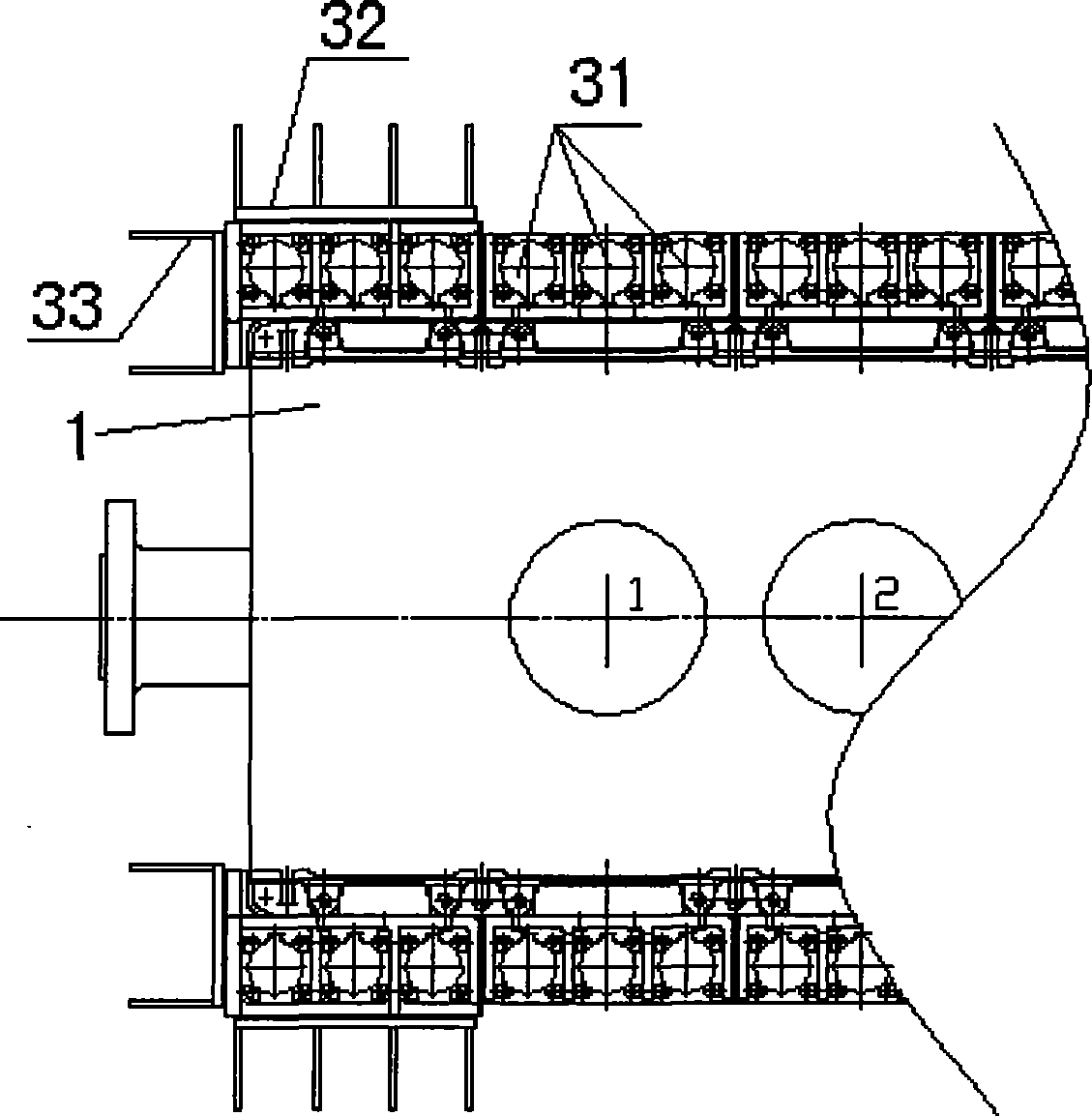

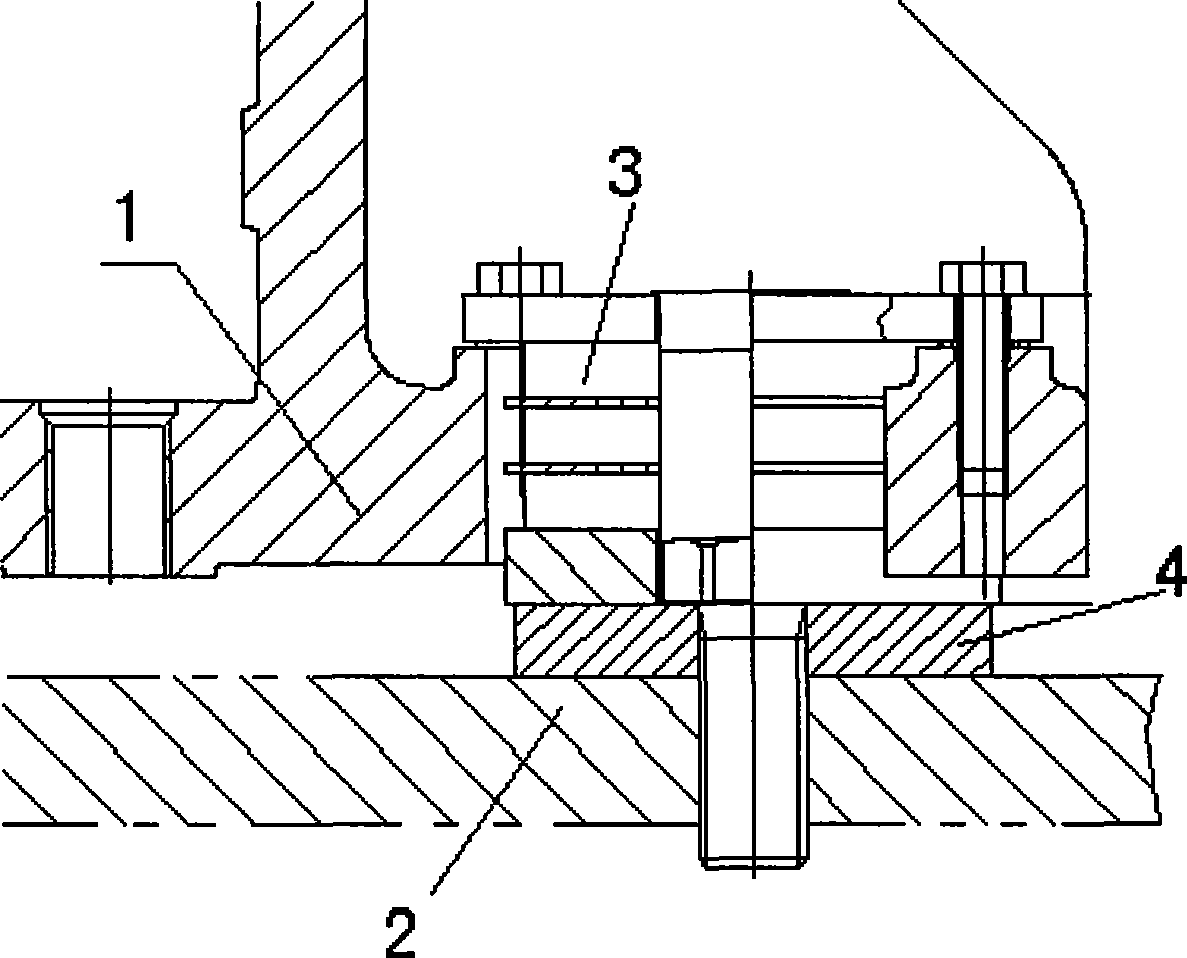

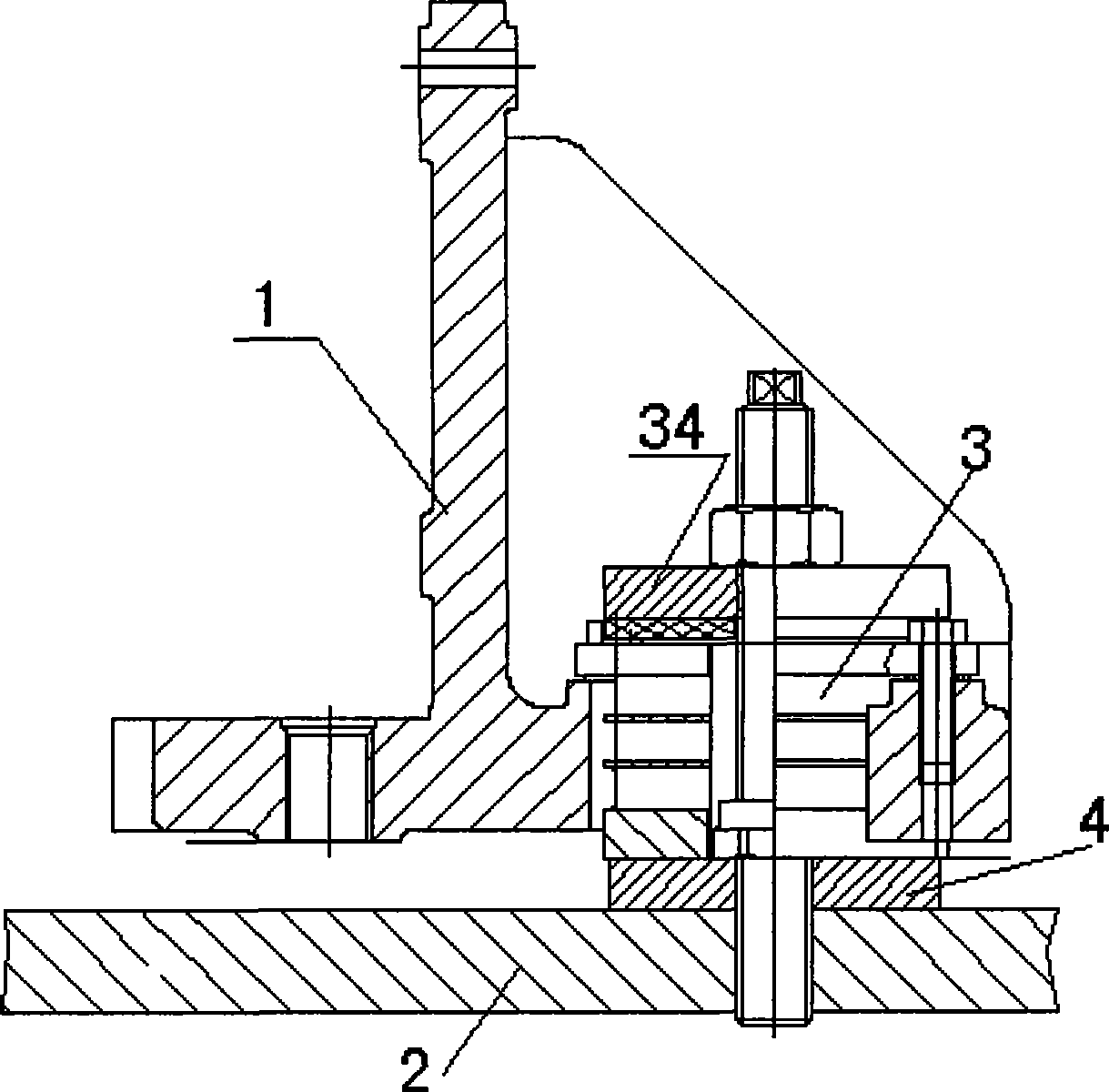

[0021] The following takes a high-tech product as an example to describe in detail a host installation method with elastic damping block and elastic support of the present invention, such as figure 1 As shown in Figure 2, the mainframe includes a mainframe base 1 and a mainframe base 2. The mainframe base and the mainframe base are connected by an elastic support 3. The elastic support includes a vertical shock-absorbing block 31 and a lateral The shock-absorbing block 32 and the longitudinal shock-absorbing block 33 include the following installation steps:

[0022] 1. According to the results of shaft alignment, use temporary supports to determine the installation position of the gearbox and the host

[0023] The main engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com