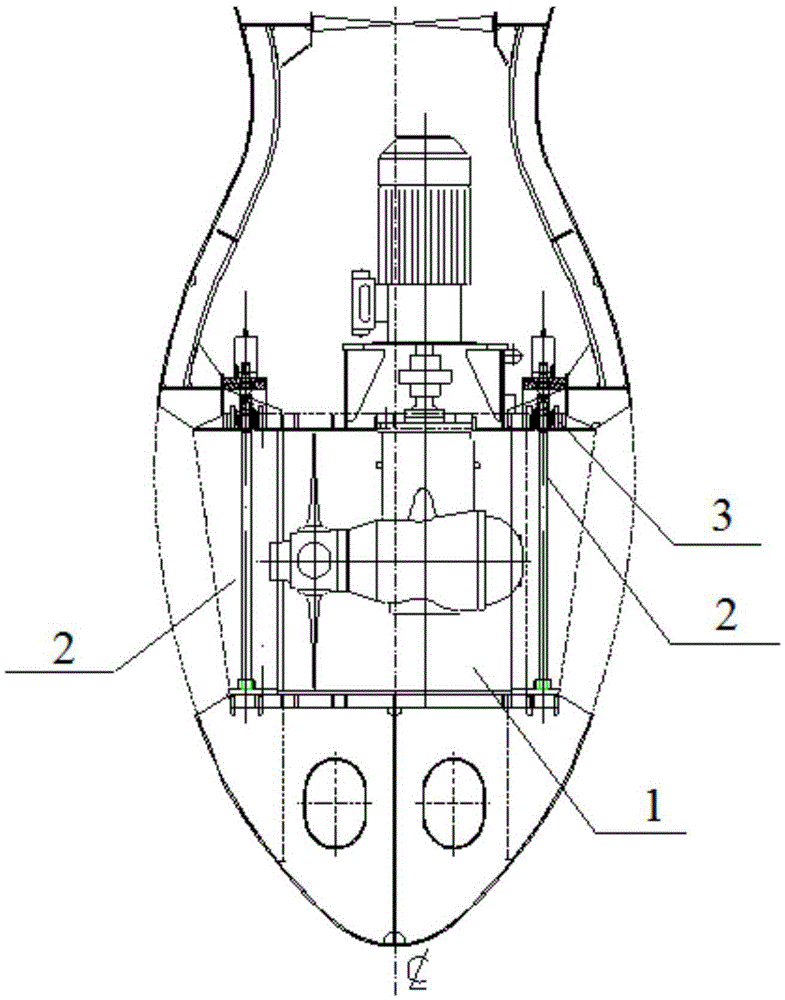

Assembling method of side-push seal cover device

A technology for assembling welding and cylinder components, which can be used in transportation and packaging, ship parts, ships, etc., and can solve the problems of long construction period and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

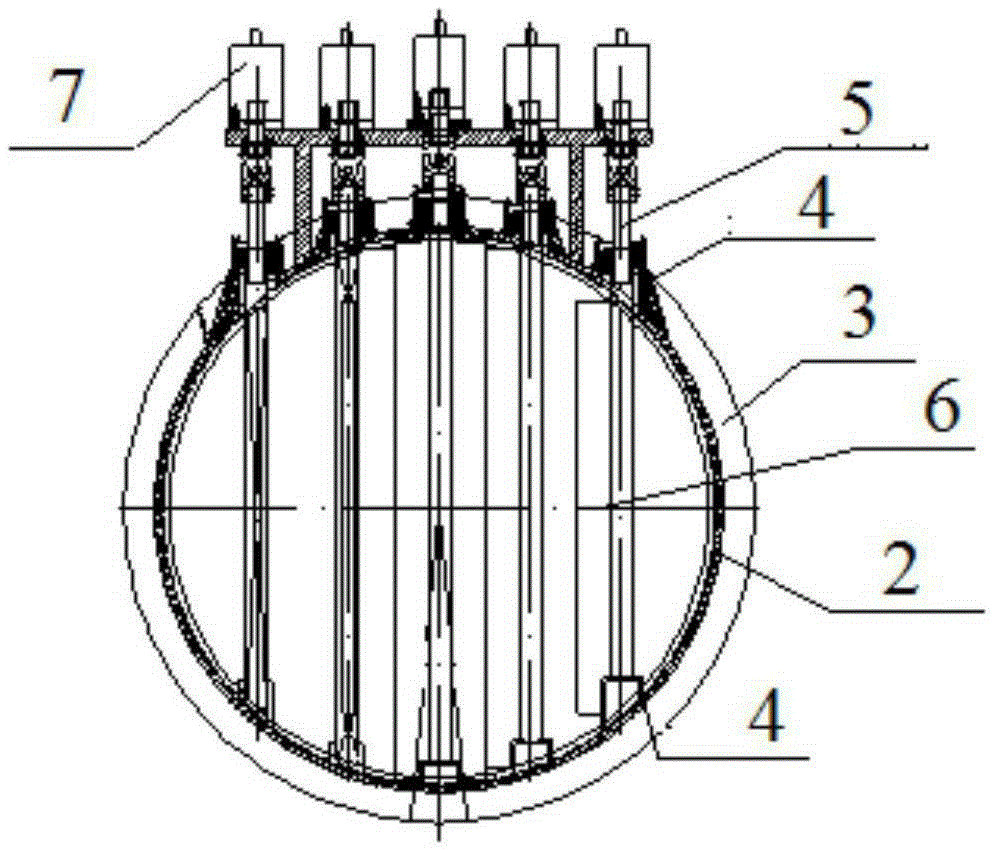

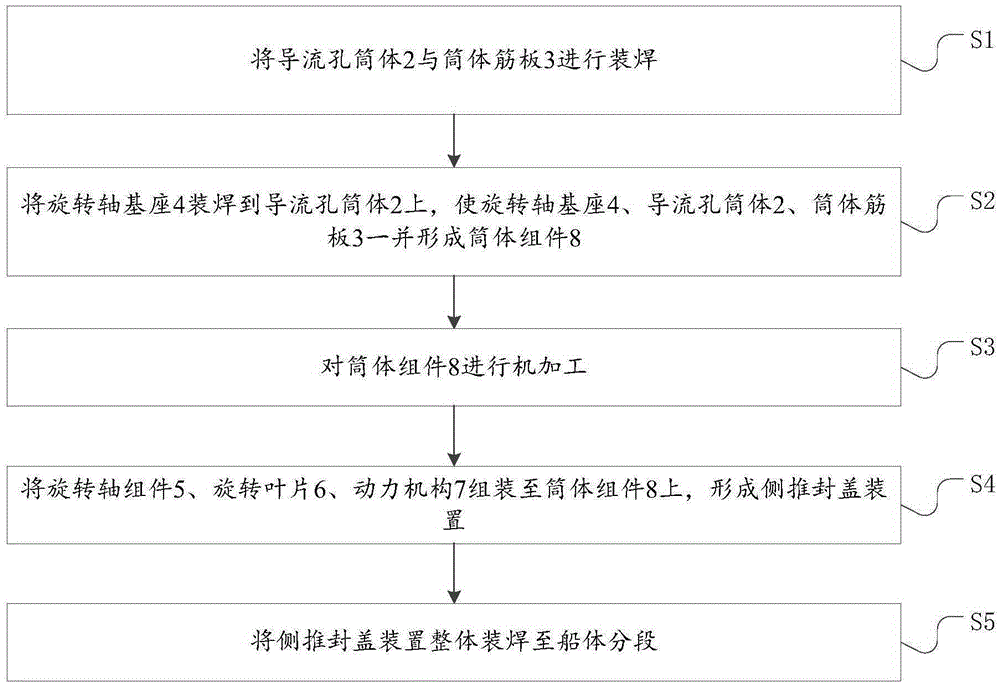

[0029] The implementation principle of the present invention is: separate part of the hull cylinder and ribs from the hull structure, weld it with the rotating shaft base in the infield to form a cylinder assembly, and transport the cylinder assembly to Machining is carried out on the machine tool. After the processing is completed, the components of the capping cylinder are tested in the field. After the assembly is completed, the cylinder components and the hull are welded in sections. The welding deformation is controlled during welding, so that the processing procedure can be changed from The interior of the ship cabin is moved to the infield, which effectively moves the process forward, reduces the difficulty of machining, and shortens the installation cycle.

[0030] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com