Pre-assembling method of large-sized ship superstructure

A superstructure and pre-assembly technology, applied in ship construction, ship components, ships, etc., can solve problems such as ship construction plans affecting the construction period of the dock, reduce the installation period and labor costs, improve the environment and economic benefits, shorten the The effect of the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

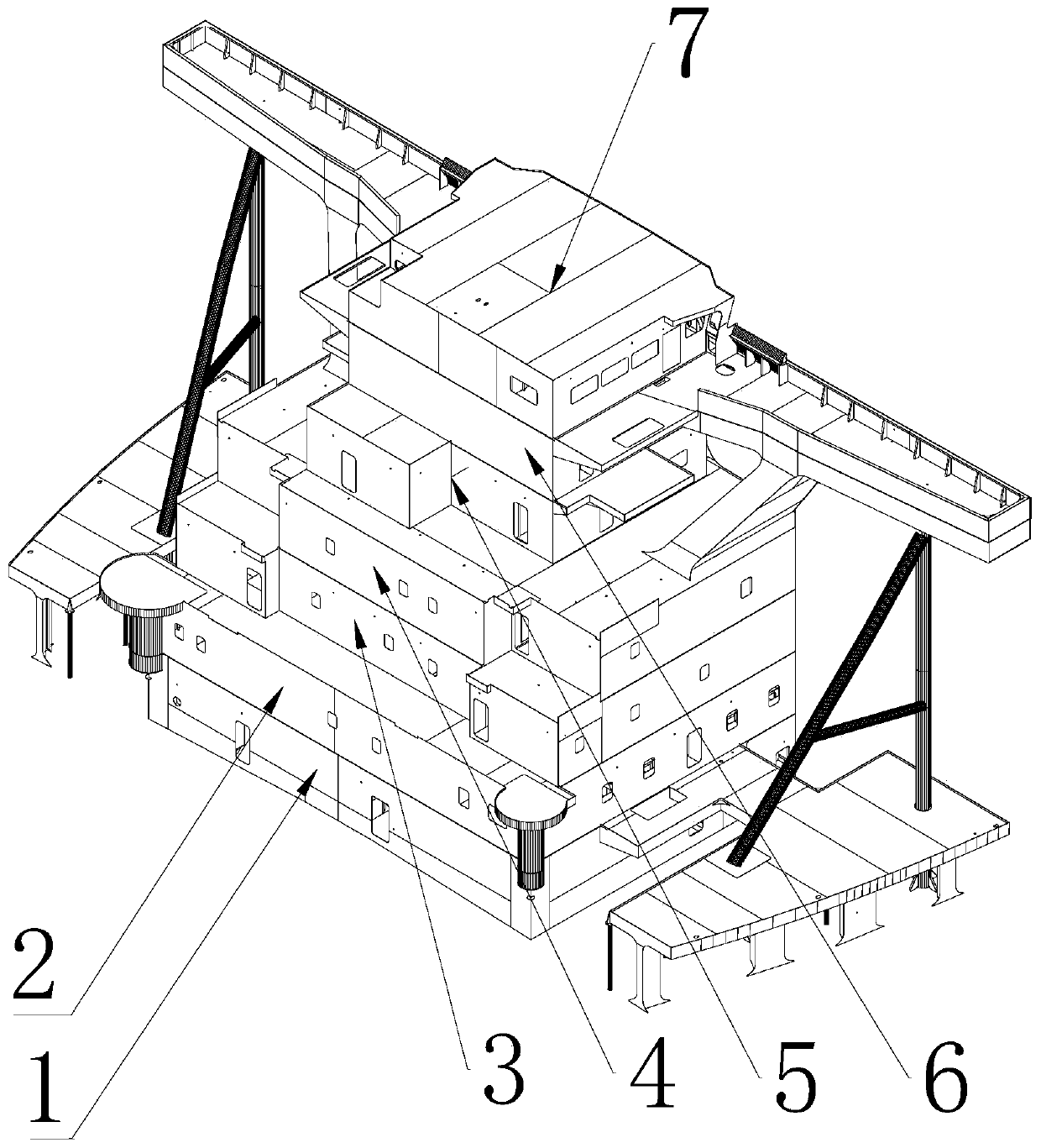

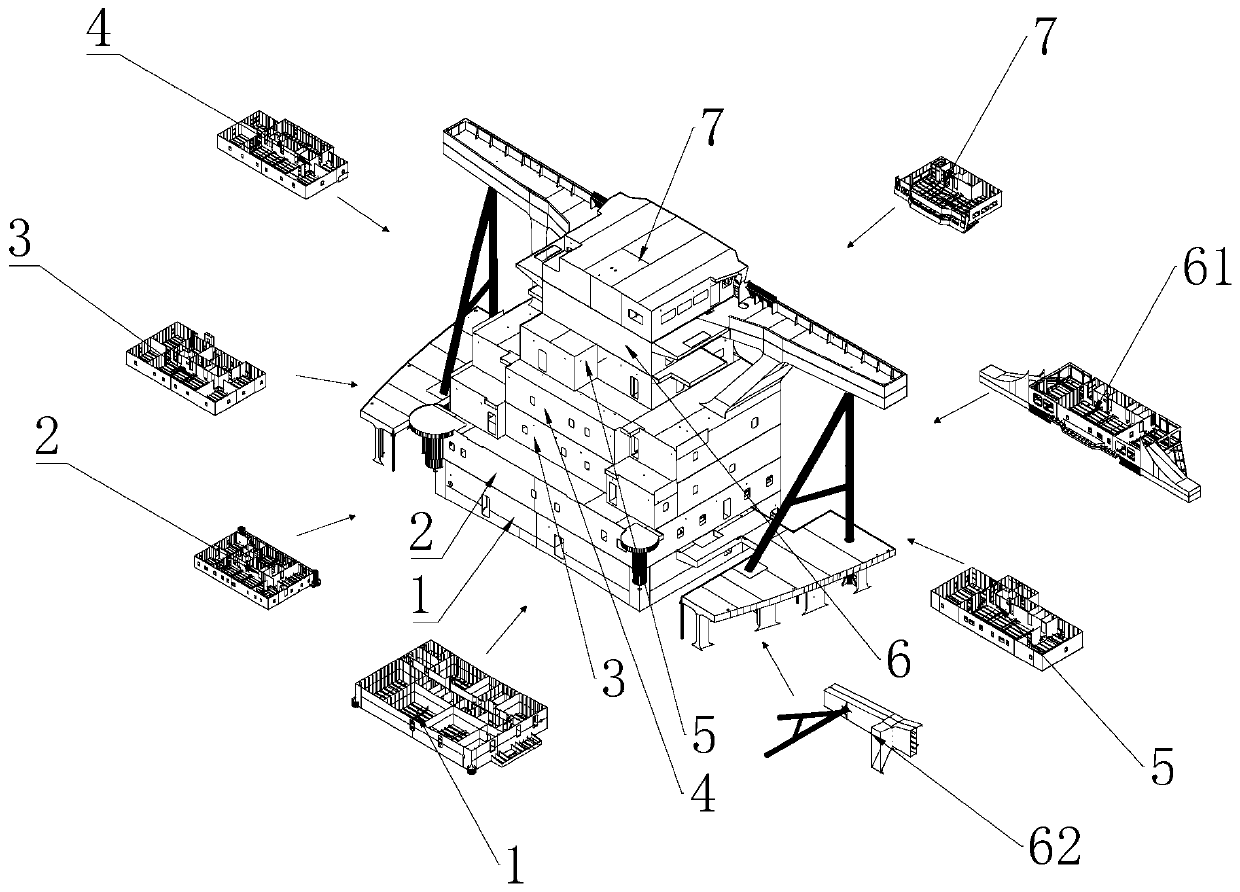

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The large ship superstructure of the present invention comprises: a first deck segment 1, a second deck segment 2, a third deck segment 3, a fourth deck segment 4, a fifth deck segment 5, and a navigation bridge deck segment 6 and compass deck segment 7; Wherein the navigating bridge deck segment 6 comprises the first sub-segment 61 and the second sub-segment 62; The pre-general group method of the large ship superstructure of the present invention comprises the following steps:

[0014] (1) hoisting the first deck segment 1 as a positioning segment for tire positioning;

[0015] (2) The second deck segment 2, the third deck segment 3, the fourth deck segment 4, the fifth deck segment 5, the first sub-segment 61, the second sub-segment 62 and the compass deck segment 7 Carry out positioning installation. Simultaneously carry out ship iron outfitting, ship pipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com