Numerical control bending machine transmission system and numerical control bending machine

A technology of transmission system and bending machine, applied in the field of bending machine, can solve the problems of poor processing accuracy and accuracy consistency, aging oil leakage of hydraulic system parts, deflection affecting the accuracy of processed parts, etc., to achieve the improvement of processing accuracy and consistency of precision Sex, the effect of overcoming deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

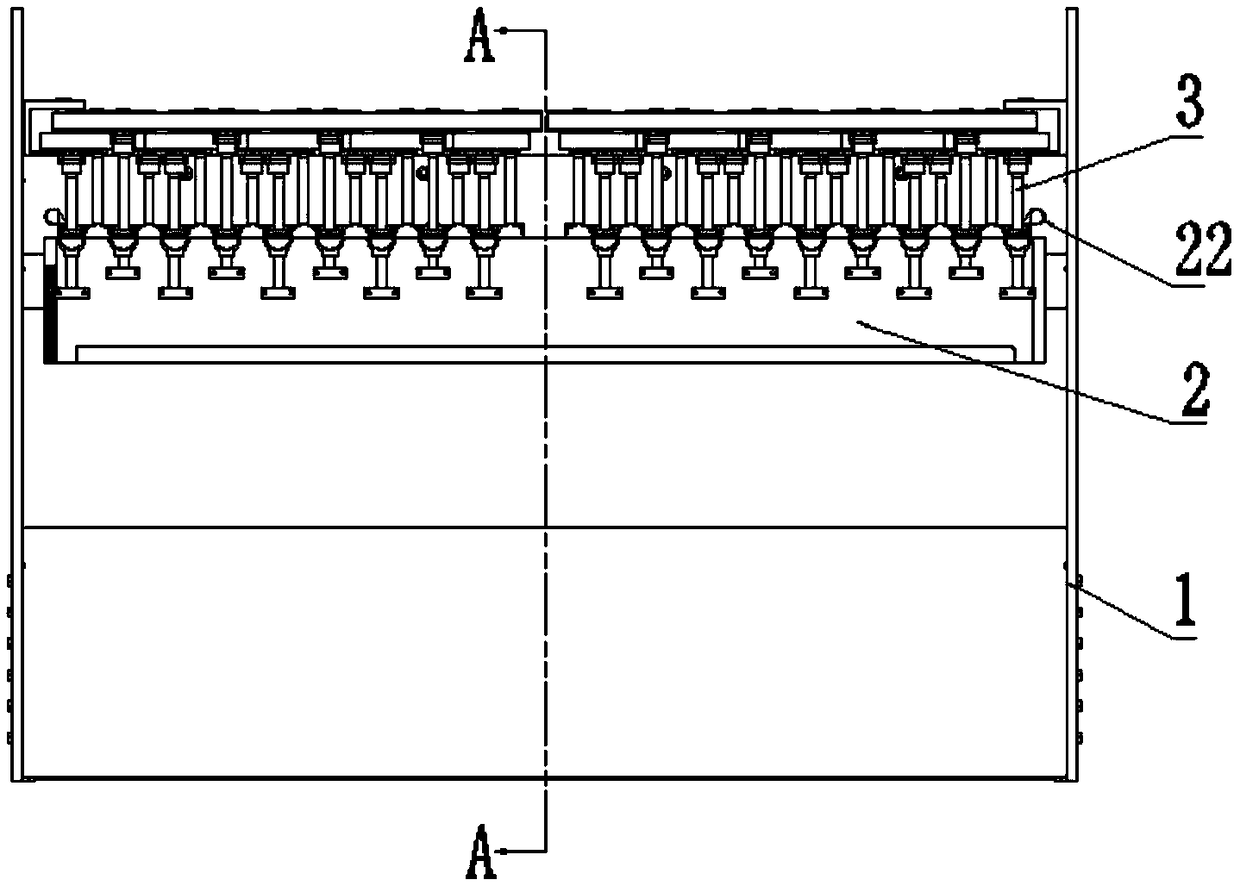

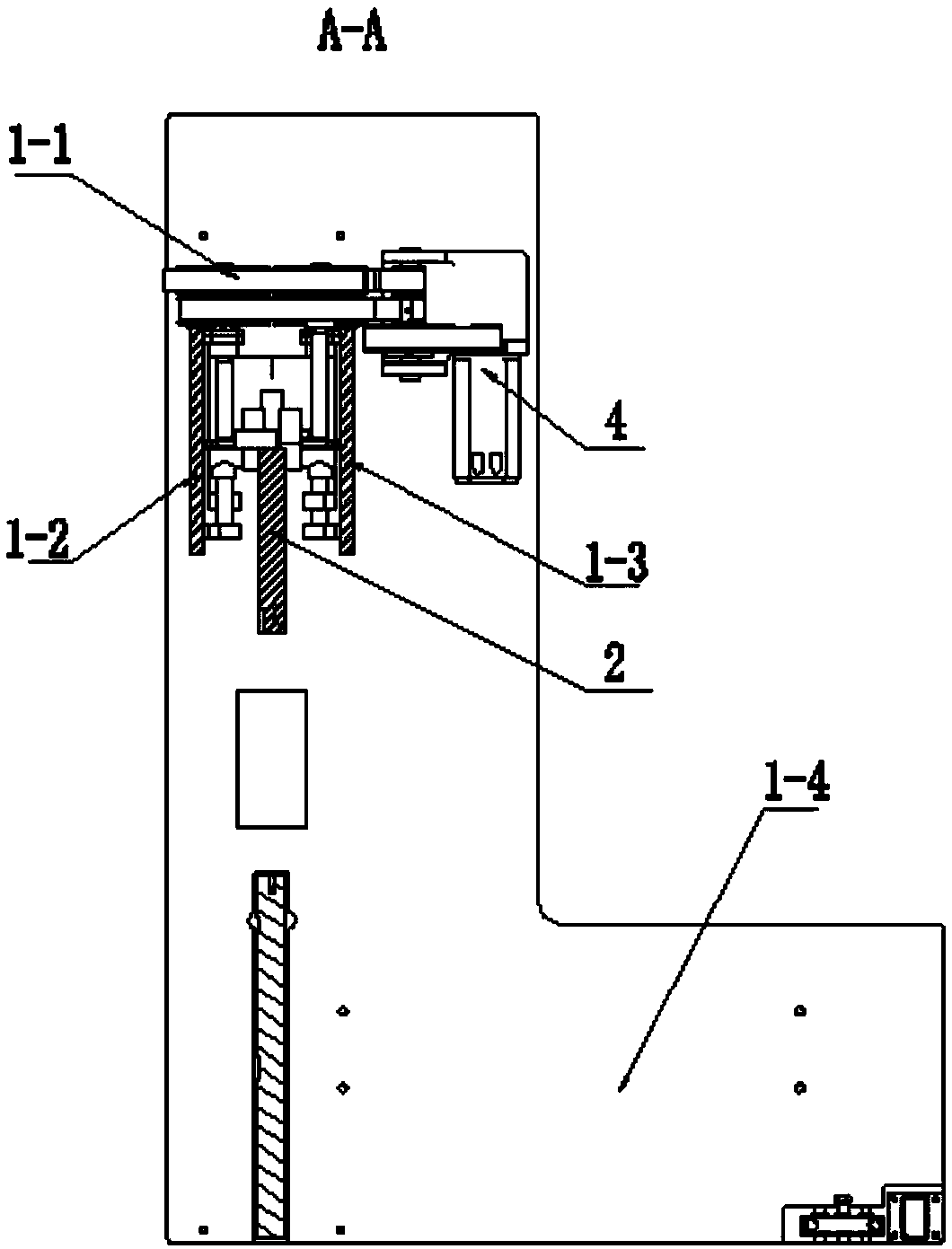

[0033] Such as Figure 1 to Figure 3 As shown, a CNC bending machine transmission system includes a slider body 2 and a ball screw drive mechanism 3. The slider body 2 is evenly distributed with force-bearing parts, and the ball screw drive mechanism 3 is provided with multiple One, the ball screw drive mechanism 3 exerts a downward force on the slider body 2 through the force-bearing member on the slider body 2 .

[0034] In the present invention, a plurality of force-bearing parts are arranged on the slider body, and the ball screw drive mechanism directly exerts force on the force-bearing parts, and then applies force to the slider body through the force-bearing parts, because the force-bearing parts are evenly distributed on the slider body Therefore, the force distribution on the entire slider body is relatively uniform, and the slider body moves downward to realize the bending process of the parts, and the bending force exerted by the slider body on the parts is evenly d...

Embodiment 2

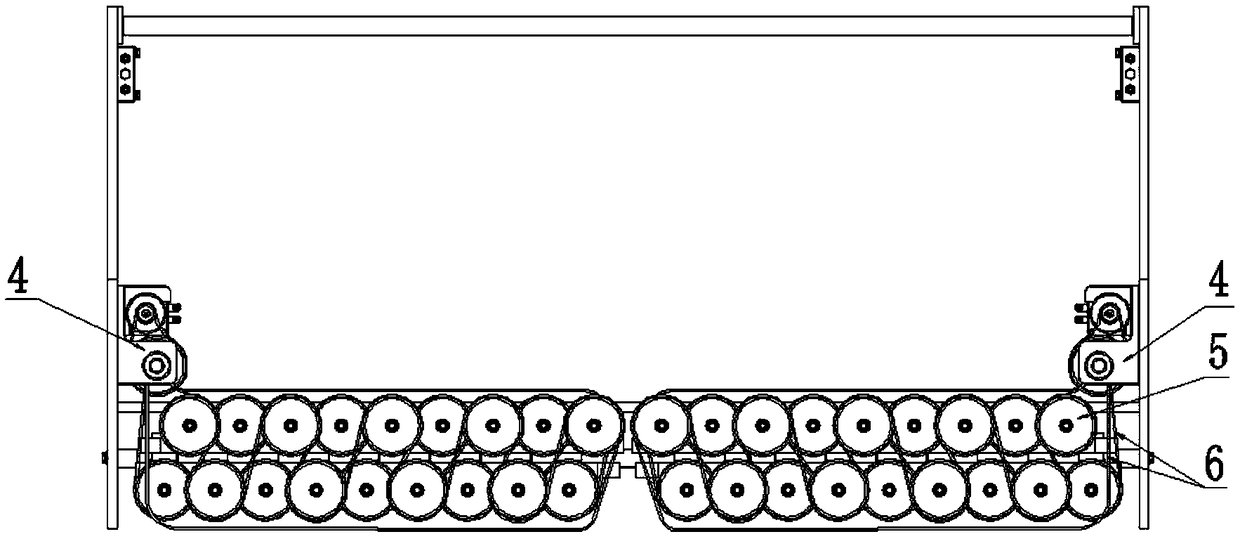

[0050] Such as Figure 6 to Figure 8 As shown, a CNC bending machine transmission system includes a slider body 2 and a ball screw drive mechanism 3. The slider body 2 is evenly distributed with force-bearing parts, and the ball screw drive mechanism 3 is provided with multiple One, the ball screw drive mechanism 3 exerts a downward force on the slider body 2 through the force-bearing member on the slider body 2 .

[0051] In the present invention, a plurality of force-bearing parts are arranged on the slider body 2, and the ball screw drive mechanism 3 directly exerts force on the force-bearing parts, and then applies force to the slider body 2 through the force-bearing parts. Since the force-bearing parts are evenly distributed on the The slider body 2, so the force distribution on the entire slider body 2 is relatively uniform, the slider body 2 moves downward to realize the bending process of the part, and the bending force exerted by the slider body 2 on the part is evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com