Cold precision forging technique for Z type contacts

A cold precision forging and contact finger technology is applied to the overall precision cold forging forming process of Z-shaped contact fingers, which can solve the problems of difficulty in ensuring the design shape and use requirements of the Z-shaped contact fingers, save raw materials, improve processing efficiency, Good surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

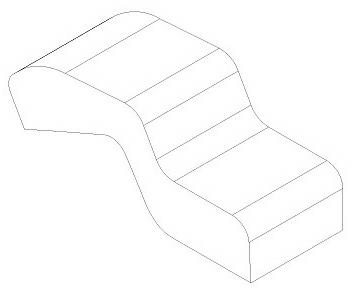

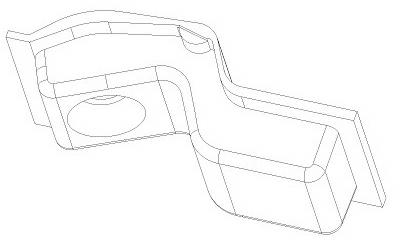

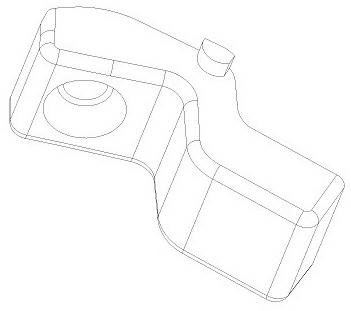

[0025] combine figure 1 — Figure 4 , using a 7mm×10.5mm T2Y copper bar directly into the die for blanking and preforming, that is, blanking and preforming are completed in a pair of molds at the same time. The preform is heated at a temperature of 600°-700°C, held for 1.5-3 hours, and then air-cooled or water-cooled; after the above-mentioned annealing and softening treatment, the annealing hardness of the preform is controlled to be HB40-45. The annealed and softened preform is polished in a finishing machine to remove defects such as burrs and oxide scales, and then cleaned, cleaned and air-dried, and then coated with zinc stearate powder lubricant. The preformed part after the above treatment is formed by cold precision forging. During the final forming process of cold precision forging, one hole is extruded, and the other hole is only pressed into a tapered hole, leaving a small amount of margin on the edge of the hole. The reason for the allowance is that the angle bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com