External thread rapid detection tool, manufacturing method and using method thereof

A technology of external threads and inspection tools, applied in the direction of mechanical devices, instruments, measuring gauges, etc., can solve the problem of affecting the large-scale production and product quality inspection of pipe fittings products, failing to meet the consistency requirements of product quality inspection results, and unable to characterize batches Problems such as the overall quality of the product, to achieve the effect of improving reusability, solving the tediousness of testing operations, and being suitable for batch processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

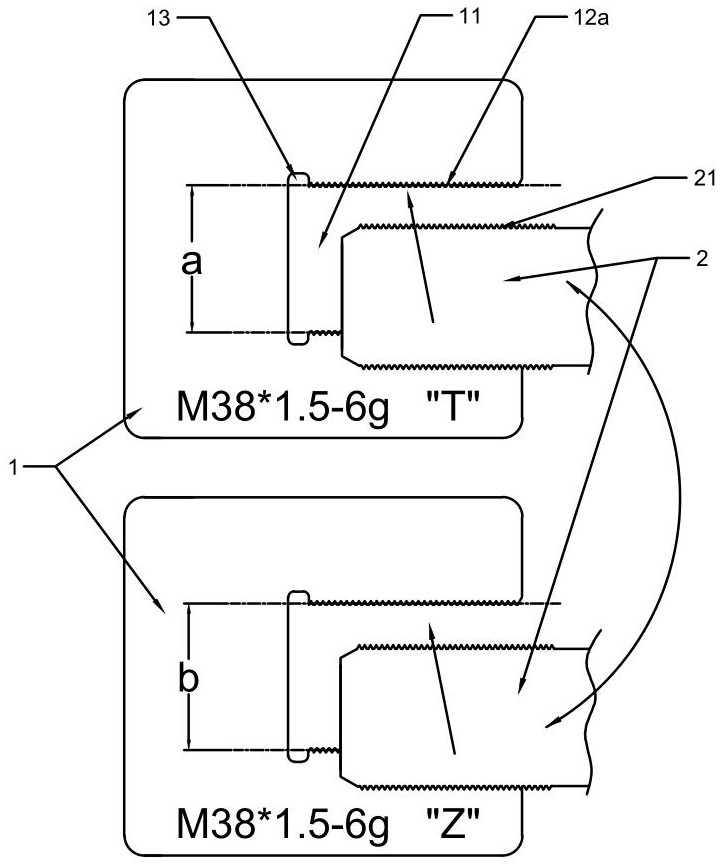

[0022] Embodiment 1, the quick inspection tool faces the external thread provided at the end of the pipe for inspection. Such as figure 1 As shown, the main body of the checker is a rigid block 1 provided with a straight-side notch 11. A pair of parallel and opposite wall surfaces are formed on the inside of the straight-side notch 11, and the wall surface processing is provided with parallel and distributed along the depth direction of the straight-side notch. The first linear tooth groove 12a, the first linear tooth groove 12a is processed corresponding to the profile angle, pitch, major diameter, middle diameter, and minor diameter of the external thread 21 of the detection object 2, and the specifications and preset level tolerances. The detection object 2 The external thread 21 is aligned with the first linear tooth groove 12a and linear slip detection is performed.

[0023] What needs to be added here is that the above pair of wall surfaces are abstractly parallel and o...

Embodiment 2

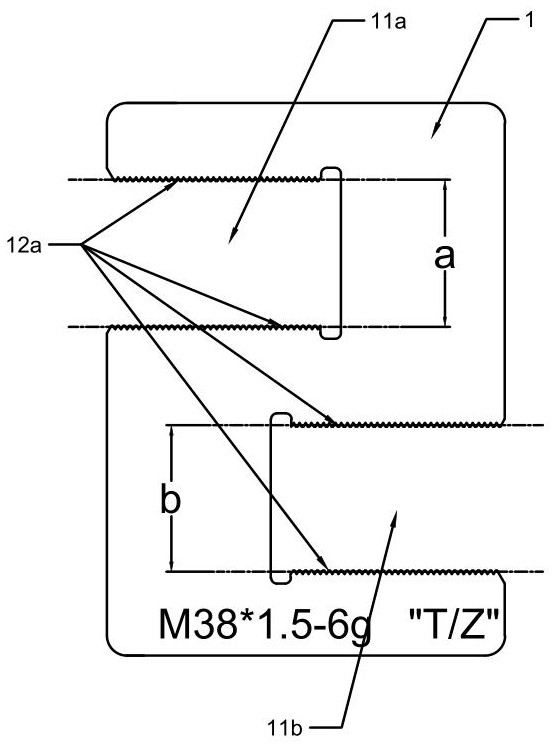

[0027] In the second embodiment, the quick inspection tool also faces the external thread provided at the end of the pipe for inspection. Most of the structural features and performance requirements of Embodiment 1 are the same. And the difference is as figure 2 As shown, the gage satisfies both the pass gauge part and the stop gauge part. And it is only realized by the machining of a rigid block. Specifically, the rigid block is provided with two dislocated straight-edge notches 11a and 11b with opposite openings, and the first linear tooth groove 12a is processed and formed in one of the straight-edge notches 11a according to the parameter specifications of the general specification, and the other A first linear tooth groove is processed and formed in a straight edge notch 11b according to the parameter specification of the stop gauge. In this way, the function realization is basically the same as that of the first embodiment, so the details are omitted, but the inspecti...

Embodiment 3

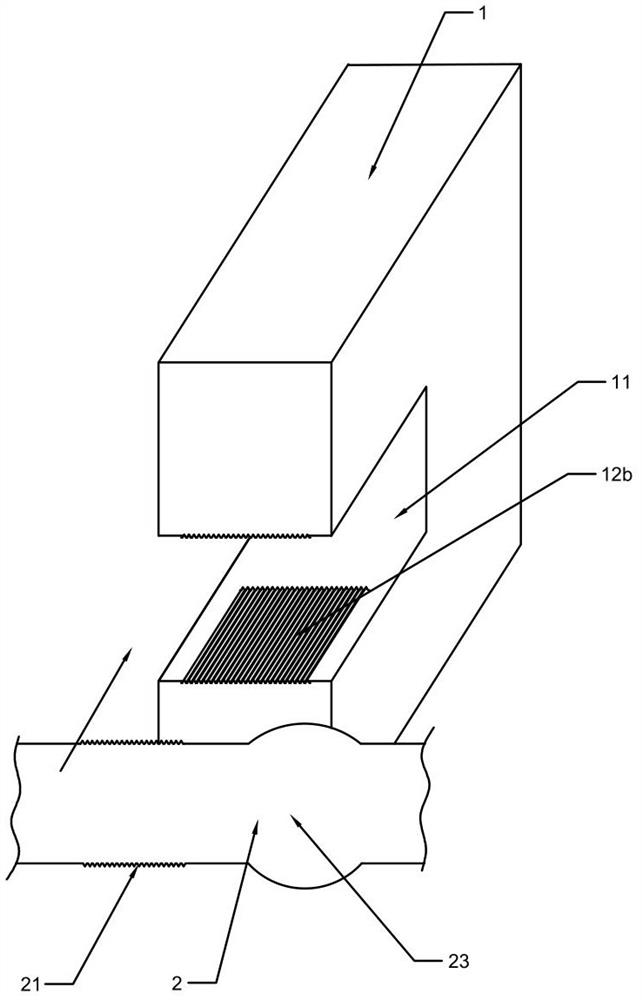

[0028] In the third embodiment, the quick inspection tool is used to detect the external thread provided in the middle section of the pipe fitting. Such as image 3 As shown, the main body of the inspection tool is a rigid block 1 provided with at least one straight-side notch 11, and a pair of parallel and opposite walls are formed inside the straight-side notch 11, and the depth of the straight-side notch is greater than the nominal radius of the test object. The wall surface processing is provided with second linear tooth grooves 12b distributed along the thickness direction of the rigid block and arranged side by side. The second linear tooth grooves 12b correspond to the specifications of the profile angle, pitch, major diameter, middle diameter, and minor diameter of the external thread of the detection object. It is processed with a preset level of tolerance, and the length of the second linear tooth groove 12b is greater than half of the depth of the straight edge notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com