Vertical engraving and milling machine spindle motor installation structure

A spindle motor and installation structure technology, which is applied in the field of machine tools, can solve the problems of long debugging and calibration time, low efficiency, and failure to meet customers' high-precision production requirements, and achieve the effect of improving debugging efficiency and reducing debugging and calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

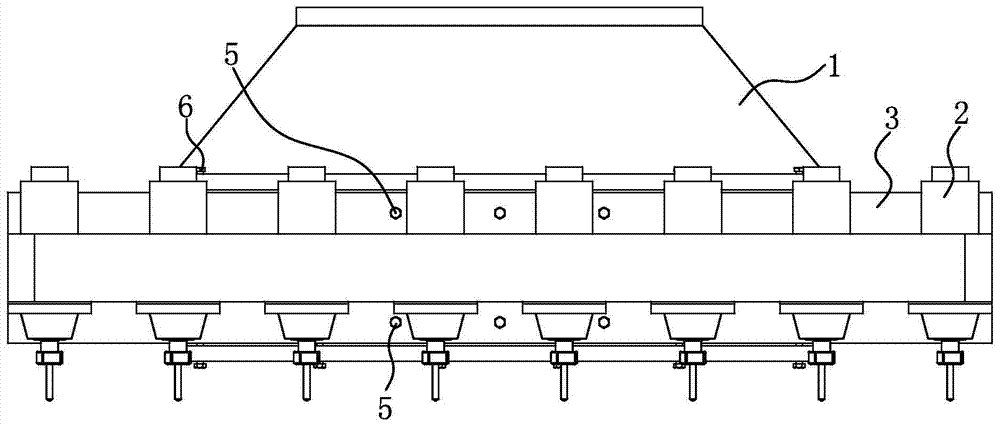

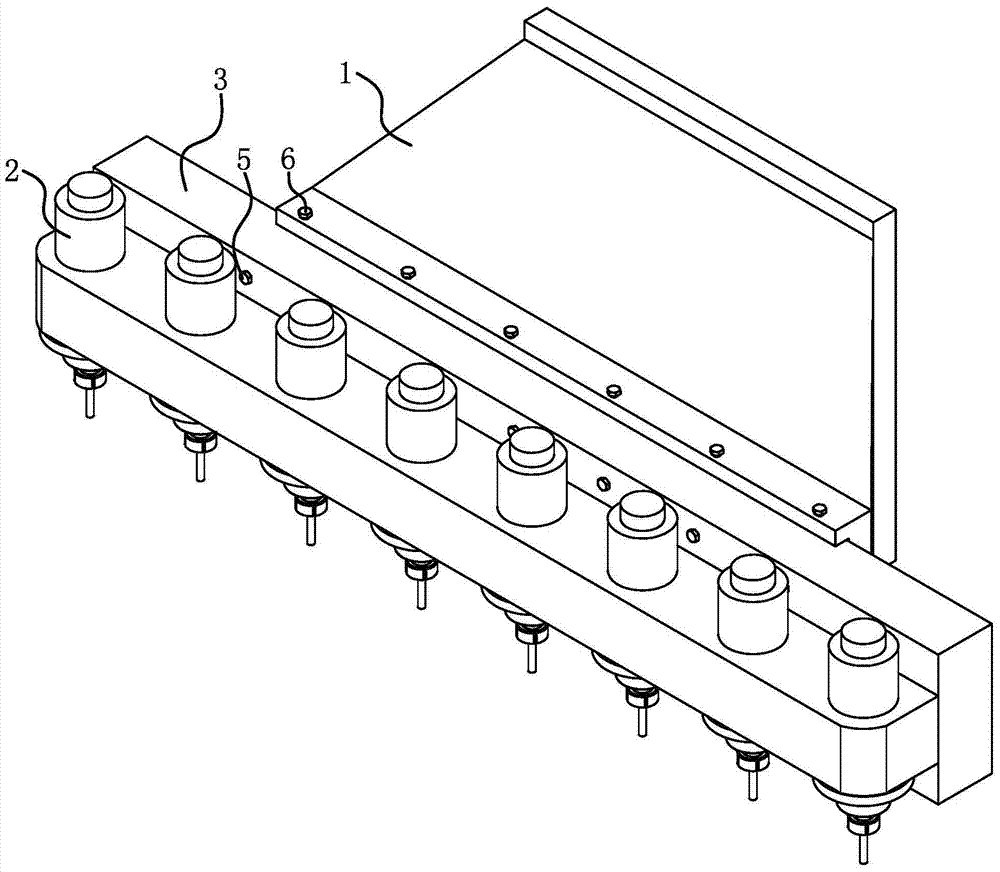

[0024] Such as Figure 1 to Figure 3 As shown, the vertical engraving and milling machine includes a machine head 1 and a plurality of spindle motors 2, and the number of spindle motors 2 given in the accompanying drawings is eight.

[0025] Such as Figure 1 to Figure 6 As shown, the spindle motor installation structure of the vertical engraving and milling machine includes a bar-shaped beam 3, the spindle motor 2 is fixed on the beam 3, and the beam 3 is fixed on the machine head 1.

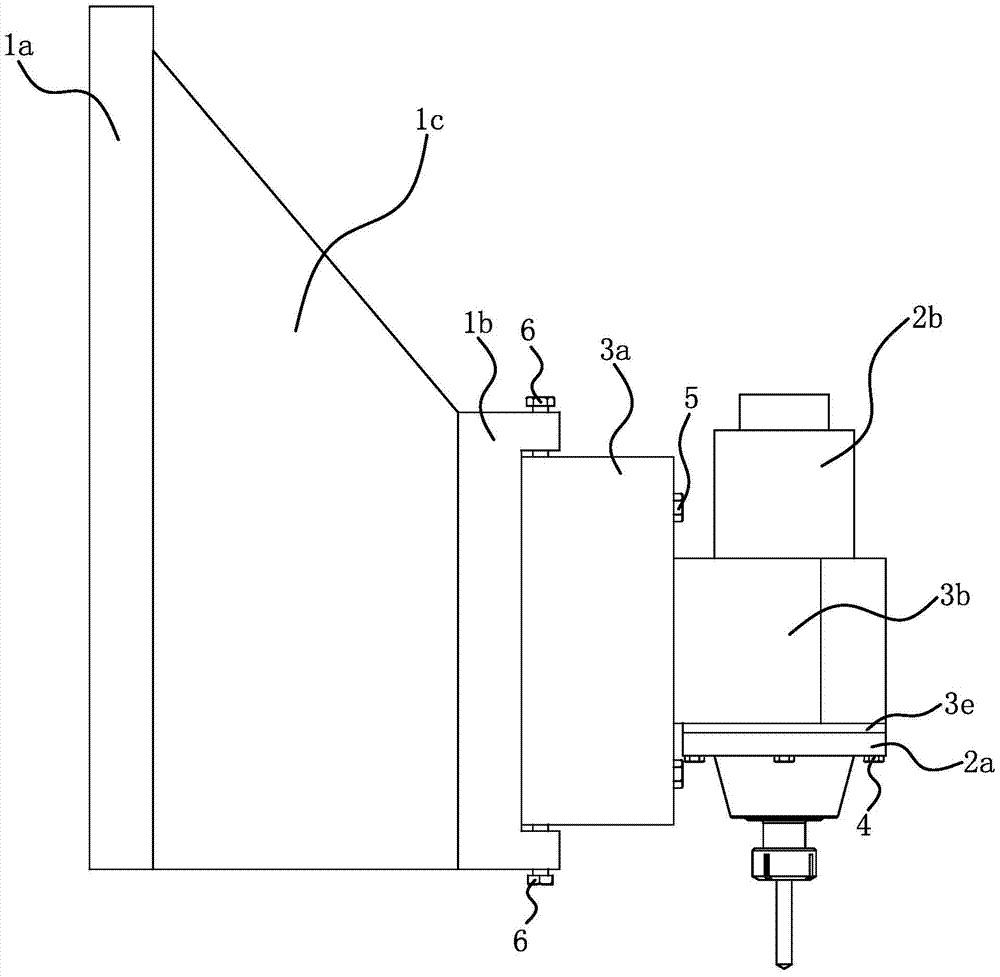

[0026] Specifically, as Figure 6 As shown, the beam 3 includes a strip-shaped bottom beam portion 3a and a strip-shaped motor seat portion 3b protruding from the bottom beam portion 3a. The cross section of the bottom beam part 3a is rectangular; it is convenient for the cross beam 3 to be connected with the machine head 1, and the bottom beam part 3a is provided with a bolt hole 3c. Eight motor installation holes 3d are distributed at equal intervals along the longitudinal direction of the...

Embodiment 2

[0031] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 7 As shown, metal strips 7 are placed between the adjusting bolt 6 and the top and bottom surfaces of the beam 3 .

Embodiment 3

[0033]The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 8 As shown, the bolt level adjustment mechanism includes a second installation groove 3f provided on the rear side of the bottom beam portion 3a of the crossbeam 3, and multiple pieces of the adjustment bolts are screwed on the upper side wall and the lower side wall of the second installation groove 3f. The bolt 6 , the crossbeam mounting plate 1b of the machine head 1 is embedded in the second mounting groove 3f, and the adjusting bolt 6 abuts against the top surface and the bottom surface of the crossbeam mounting plate 1b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com