Cleaning structure of gas gate valve

A gate valve and gas technology, which is applied to valve devices, engine components, mechanical equipment, etc., can solve the problems of high manufacturing cost, laborious disassembly of the bottom plate, and difficult cleaning of the bottom cavity of the gas valve seat, so as to reduce the manufacturing cost and facilitate cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below with reference to the drawings and specific embodiments.

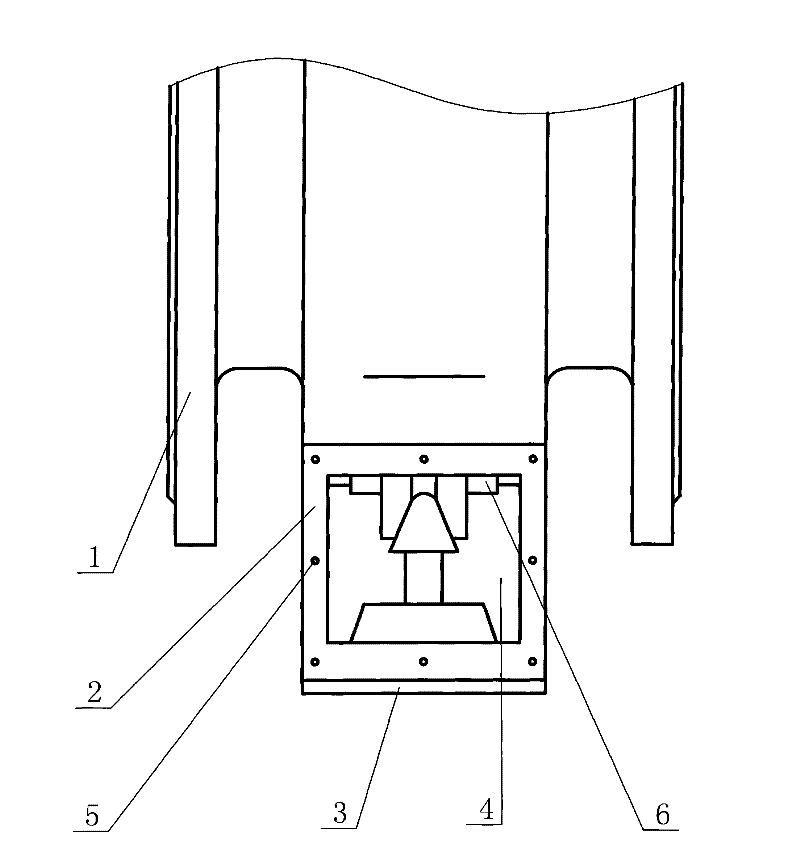

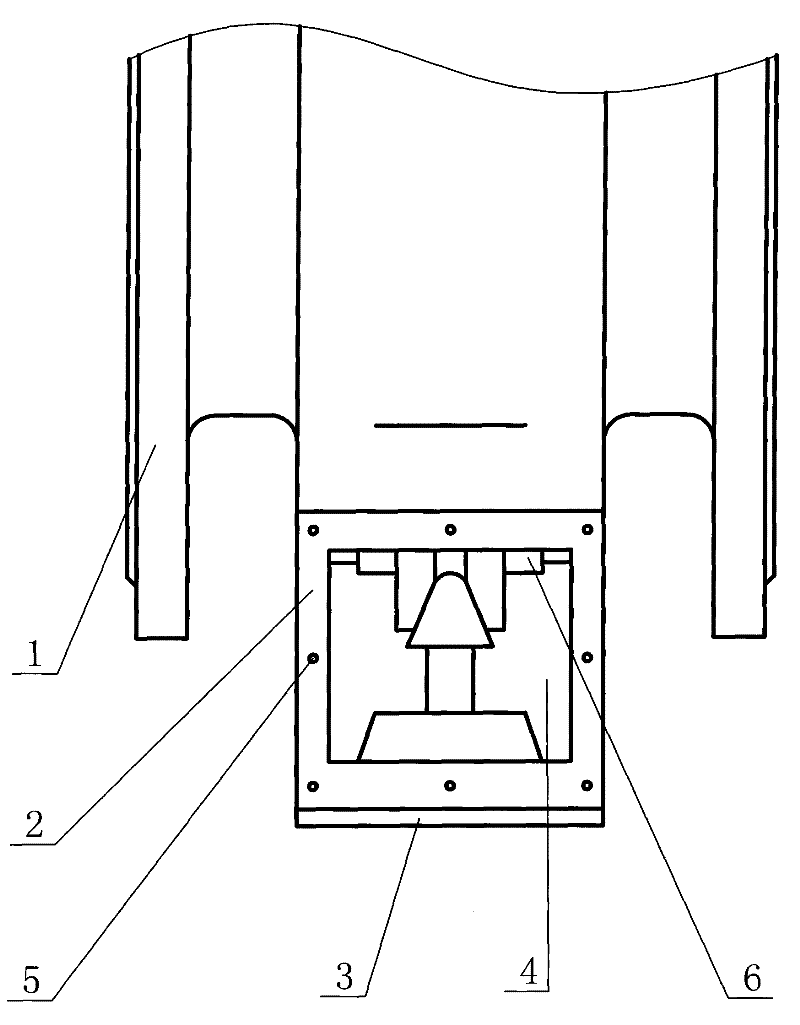

[0009] Such as figure 1 As shown, the cleaning structure of the gas gate valve includes: four side plates 2 fixedly arranged at the bottom of the valve body 1, a bottom plate 3 is fixedly arranged at the bottom of the side plate 2, and the bottom plate 3 and the side plate 2 together enclose the valve seat bottom cavity , One of the side plates 2 is provided with a cleaning port 4, and the detachable side cover is set on the side plate 2 by a number of connecting bolts to block the cleaning port 4, and the connecting bolts are matched with the mounting holes 5 provided on the side plate 2 .

[0010] Install the cleaning structure of the above structure on the gas gate valve. When it is necessary to clean the bottom cavity of the gas valve seat, use a tool to unscrew the connecting bolt from the mounting hole 5, remove the detachable side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com