Insert components for trimming gap areas

A technology for inserting components and gap areas, applied in furniture accessories, applications, household stoves, etc., can solve the problems of long production time and high production cost, and achieve the effect of reducing production time and cost, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] best practice

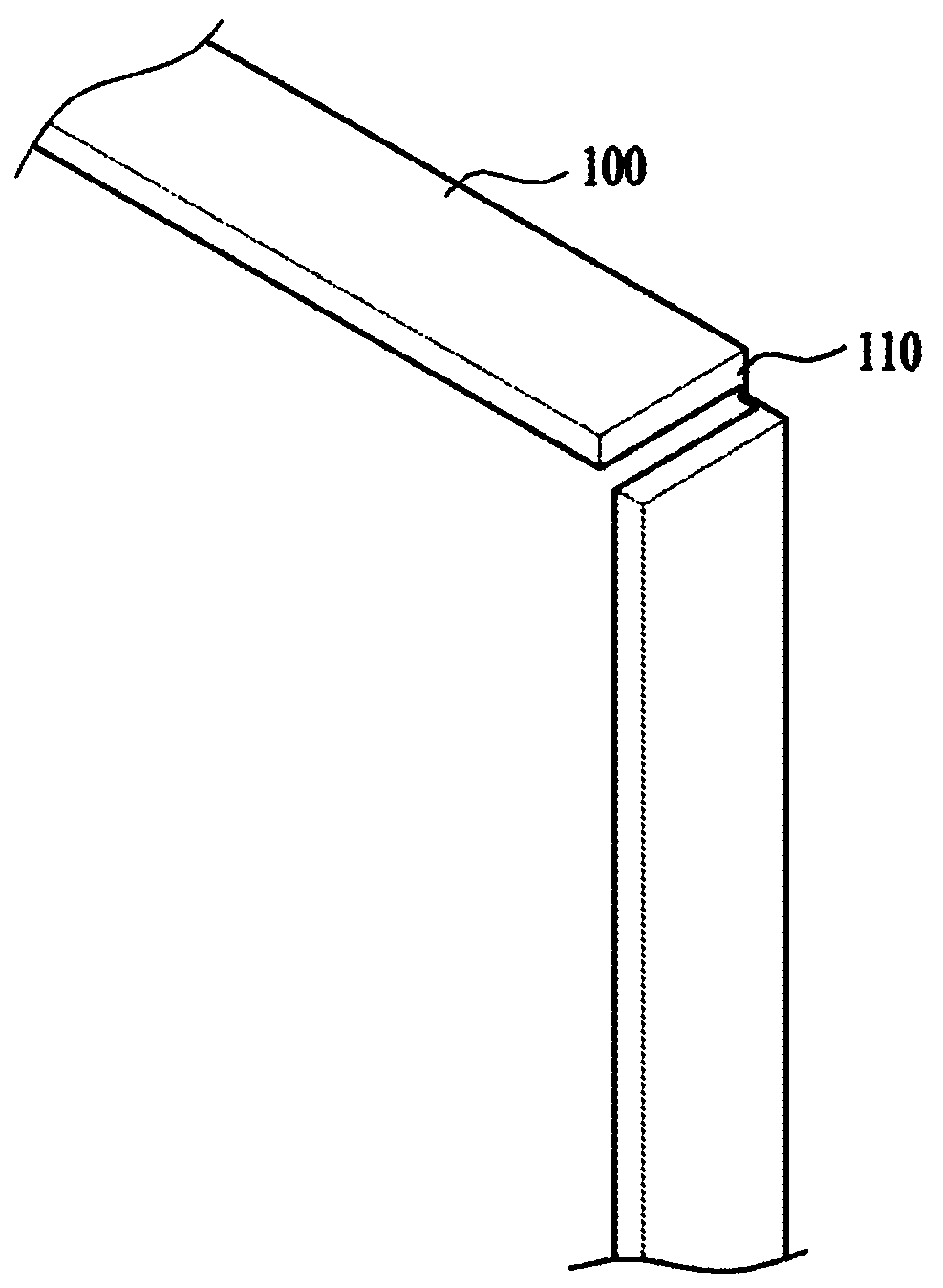

[0048] Referring to the accompanying drawings, a system for interworking between a cooking device and a kitchen device according to an embodiment of the present disclosure will be described in detail. Regardless of the reference numerals, the same or equivalent components may be provided with the same reference numerals, and descriptions thereof will not be repeated. For brief description with reference to the drawings, the size and shape of elements shown in the drawings may be exaggerated or reduced, and it should be understood that the embodiments presented herein are not limited by the drawings.

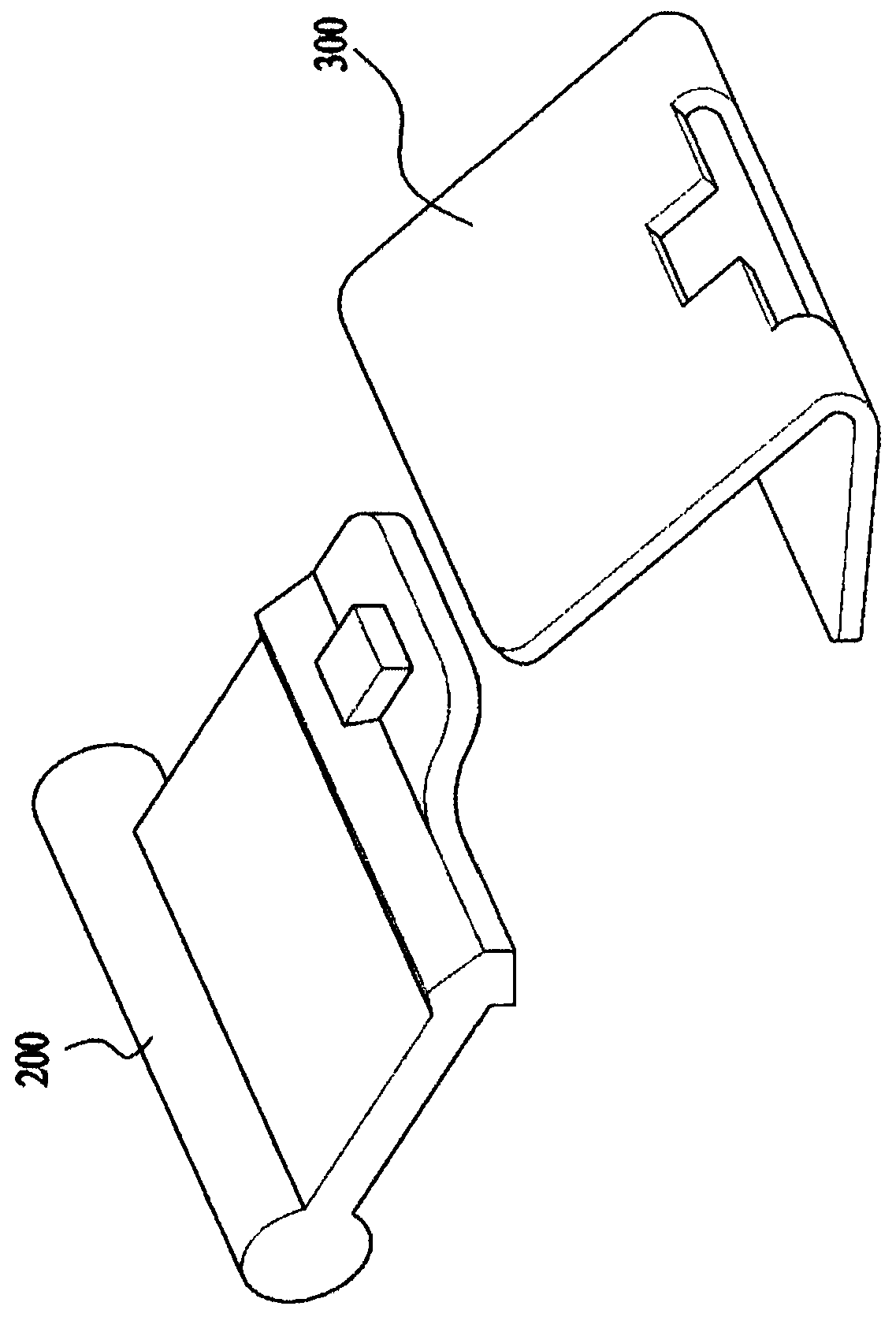

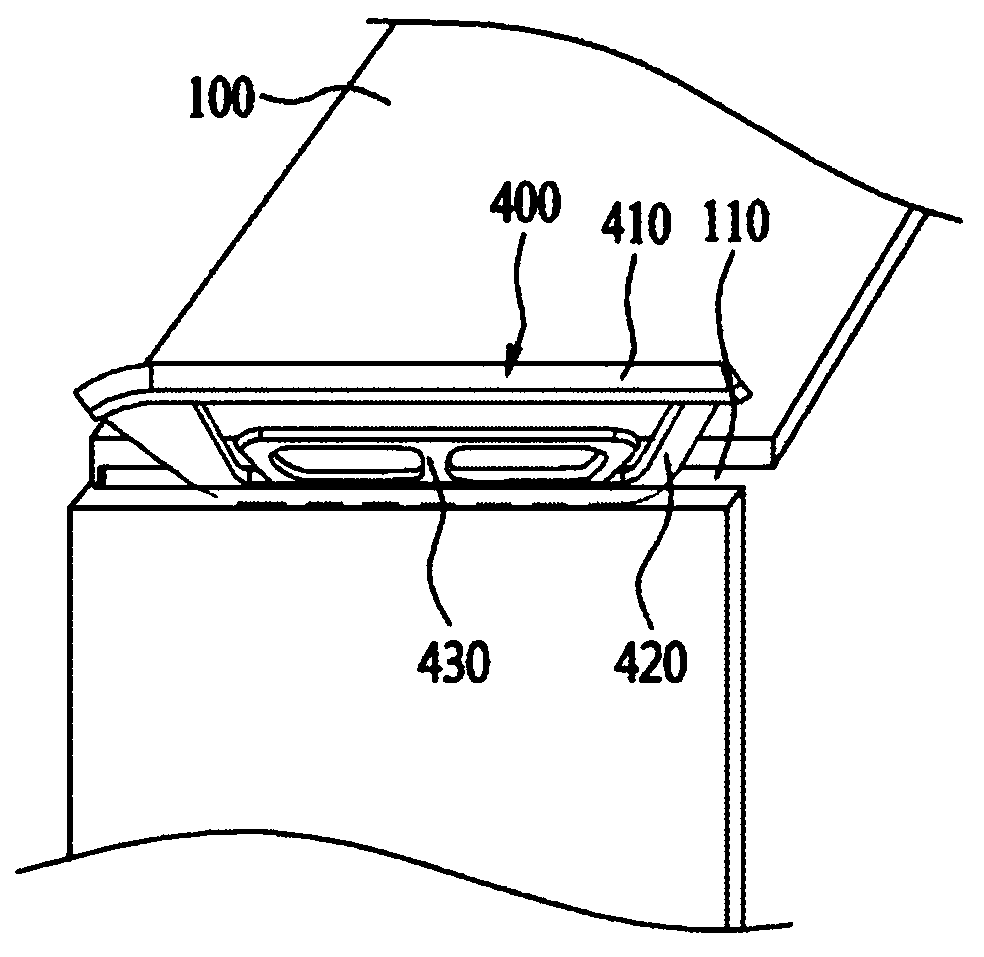

[0049] image 3 is a diagram illustrating a process of inserting an insert assembly 400 according to the present disclosure in a gap region 110 of a panel 100 to trim the insert assembly 400 .

[0050] The insertion assembly 400 includes: a body unit 410, the body unit 410 does not expose a hole or a slit (hereinafter referred to as a gap area) of the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com