Stitch electric reactor and method for manufacturing same

A technology of reactors and pins, which is applied in the field of electronic components, can solve the problems of high production costs of reactors and cumbersome production processes, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

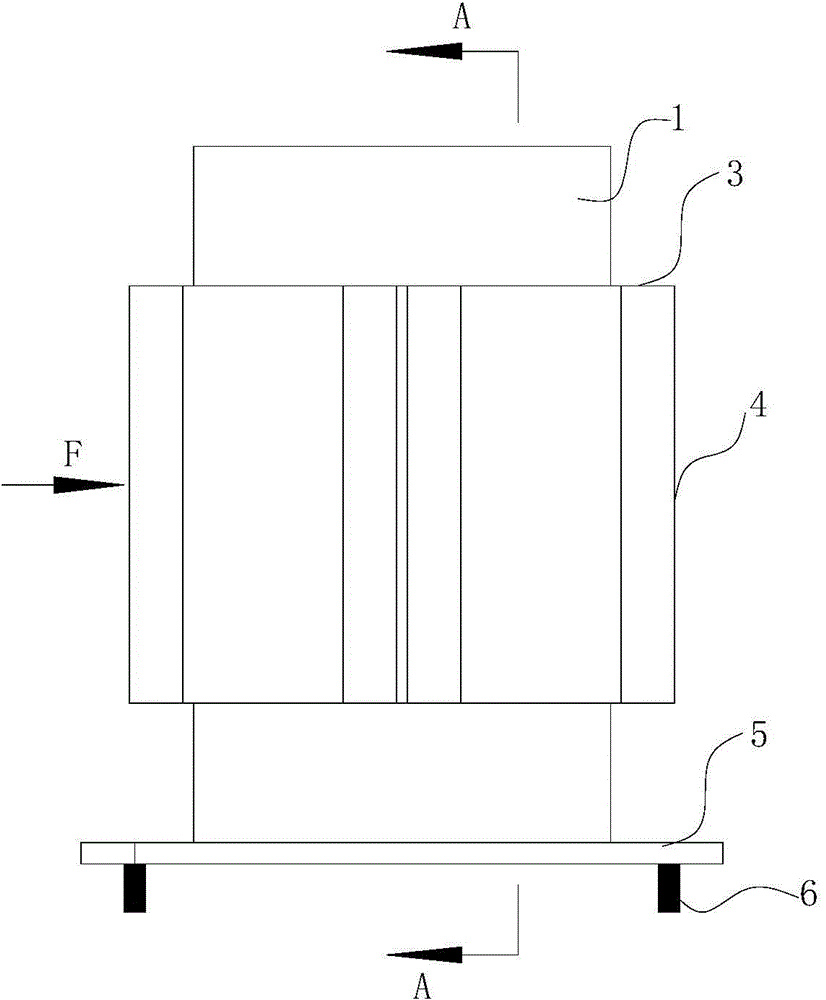

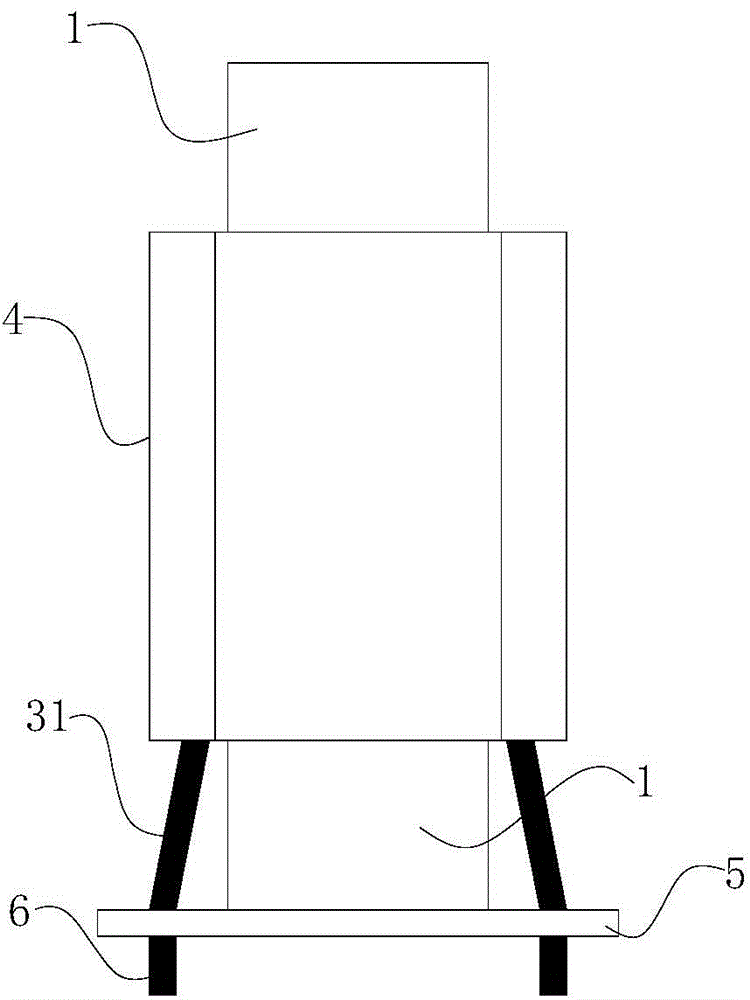

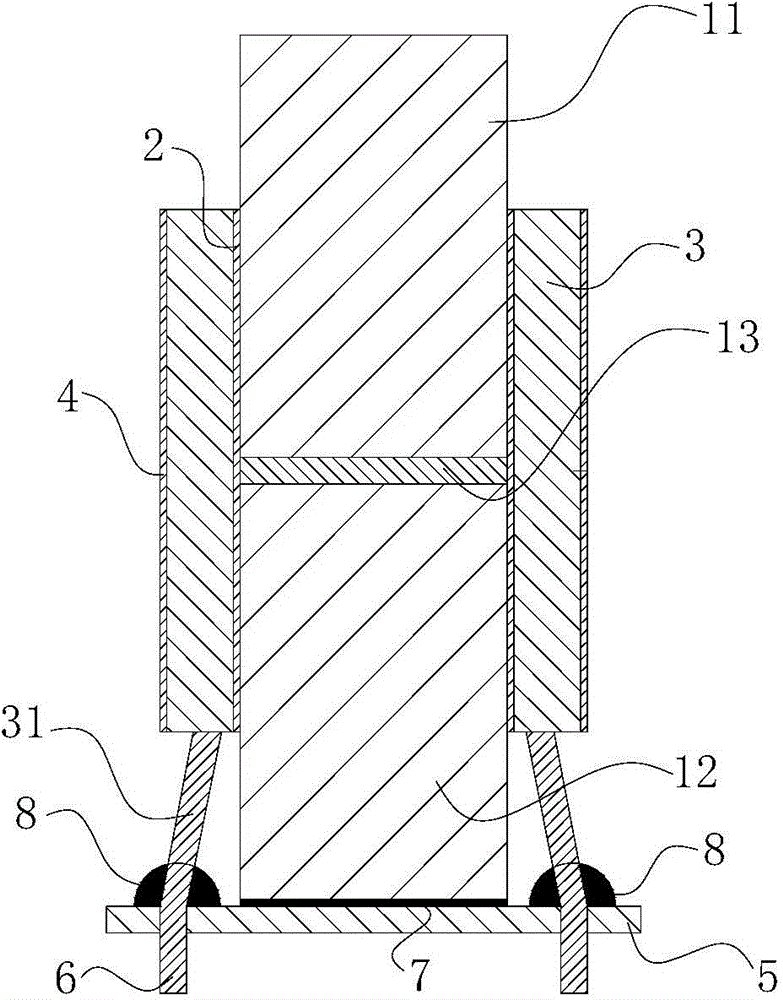

[0037] refer to Figure 1 to Figure 3 , a pin reactor according to the present invention includes an iron core 1 , an insulating frame 2 , a coil winding 3 , an insulating protective layer 4 , and an insulating base plate 5 . The iron core 1 is fixedly connected with the insulating frame 2 . The insulating frame 2 is hollow inside and has openings at both ends, and the insulating frame 2 is fixedly sheathed on the outer periphery of the iron core 1 . The coil winding 3 is a wire 31 with an insulating layer on the outer surface fixedly wound around the outer periphery of the insulating frame 2 , and both ends of the wire 31 protrude from the lower surface of the insulating frame 2 . The insulating protection layer 4 covers the outer circumference of the coil winding 3 , which can be used to protect the coil winding 3 and further fix the coil winding 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com