Kettle body structure

A pot body and spout technology, applied in the field of pot body structure, can solve the problems of difficult handle installation, high tension of the metal shell, affecting the production efficiency of electric kettles, etc., and achieve the effect of strengthening strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

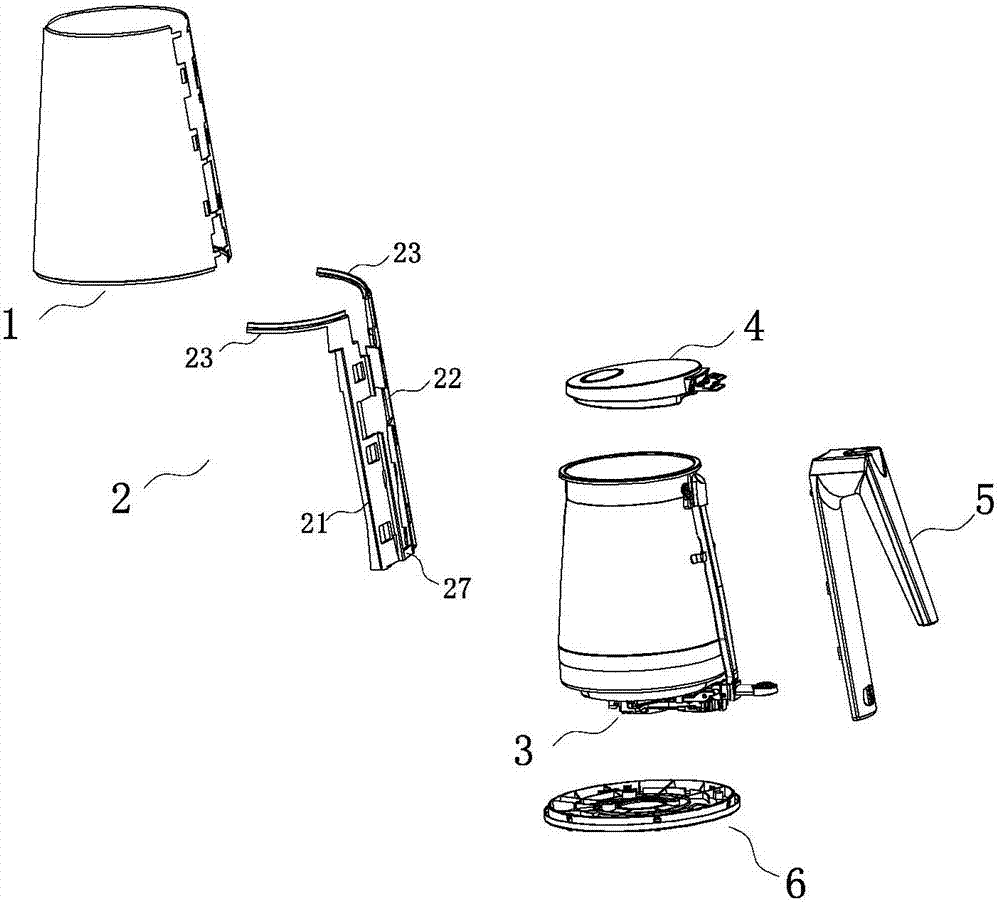

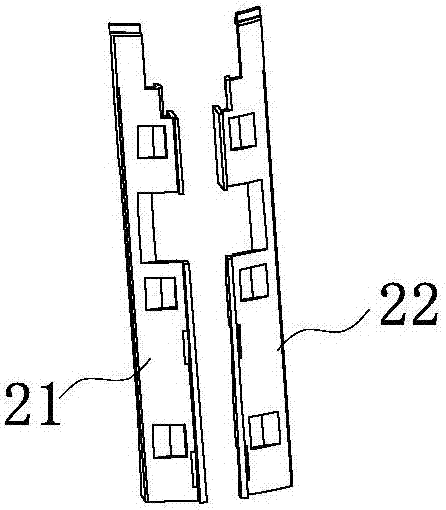

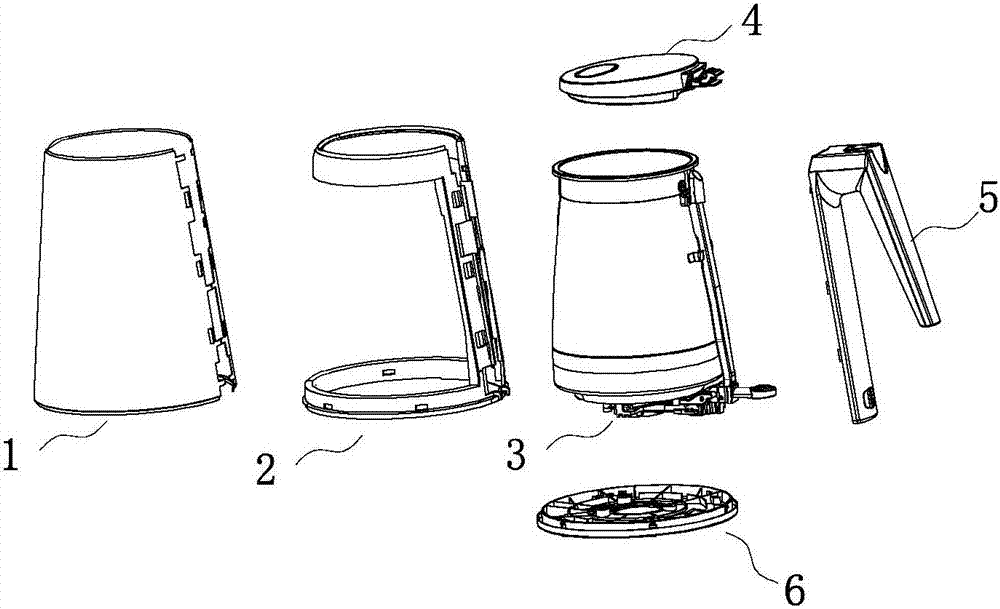

[0060] Such as Figure 1-Figure 2 As shown, a pot body structure, the pot body includes an inner tank 3, a metal shell 1, a handle 5, an opening is provided on one side of the metal shell 1, and the metal shell 1 is sleeved outside the inner tank 3 , the kettle body also includes a plastic bracket 2 arranged between the metal shell 1 and the inner tank 3, the plastic bracket 2 is used to support the metal shell 1, and the plastic bracket 2 includes a first bracket 21 and a second bracket 22, the first bracket 21 and the second bracket 22 are arranged at the opening and axially arranged along the outer wall of the inner container 3, and the handle 5 covers the opening. It needs to be explained that the first bracket 21 and the second bracket 22 are arranged axially along the outer wall of the inner tank 3 (the height direction of the inner tank 3 is taken as the axial direction for schematic illustration), which should be understood in a broad sense, for example, including the ...

Embodiment 2

[0071] The difference between this embodiment and Embodiment 1 is that the first bracket 21 and the second bracket 22 do not need to be fixed on the inner tank 3, which reduces the assembly process of the first bracket 21 and the second bracket 22 on the inner tank 3, and speeds up the assembly. efficiency, and at the same time, there is no need to set other structures on the inner tank 3 to destroy the integrity of the inner tank 3, such as horses. Reducing the above structures can also reduce costs and speed up work efficiency.

[0072] Such as Figure 3-Figure 4 As shown, a pot body structure, the pot body includes an inner tank 3, a metal shell 1, a handle 5, an opening is provided on one side of the metal shell 1, and the metal shell 1 is sleeved outside the inner tank 3 , the kettle body also includes a plastic bracket 2 arranged between the metal shell 1 and the inner tank 3, the plastic bracket 2 is used to support the metal shell 1, and the plastic bracket 2 includes ...

Embodiment 3

[0087] In the structure of the plastic bracket 2 in the above embodiment, there is no connection relationship between the first bracket 21 and the second bracket 22 (the position facing the opening of the metal shell 1), when the first bracket 21 and the second bracket 22 are not fixed When the liner 3 is placed on the inner tank 3, even if the metal shell 1 is supported by the first bracket 21 and the second bracket 22, when the tension of the metal shell 1 at the opening is relatively large, the opening will be pulled to a large opening angle and easily deformed , both ends of the opening are not closed, and the installation of the handle 5 will increase the difficulty of installation.

[0088] Such as figure 1 , Figure 3-Figure 5 As shown, based on the structure of the above embodiment, the plastic bracket 2 also includes a connecting piece 27 connecting the first bracket 21 and the second bracket 22, and the connecting piece 27 is arranged at the opening facing the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com