Shell and manufacture method thereof

A manufacturing method and shell technology, applied in electrical equipment shells/cabinets/drawers, other household appliances, ion implantation plating, etc., can solve problems such as insufficient mechanical strength, increased assembly steps, and inability to meet radio frequency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

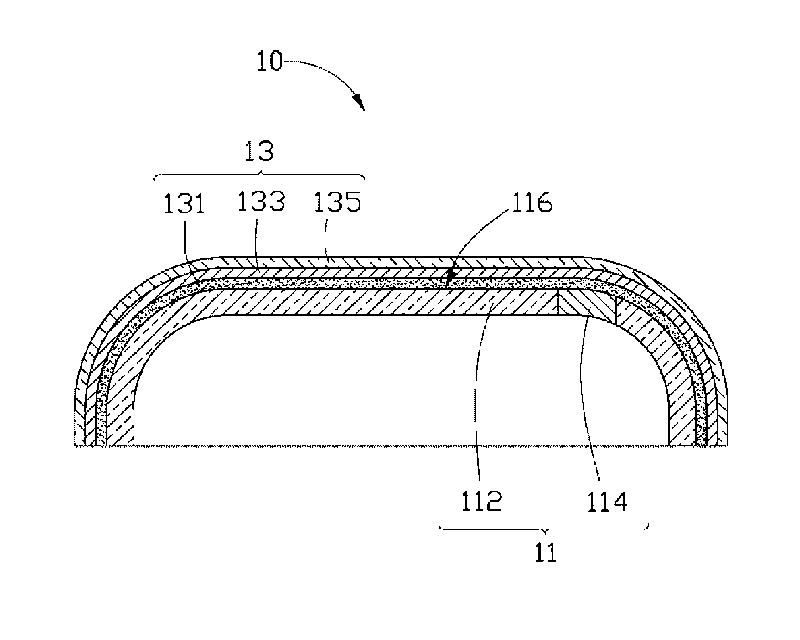

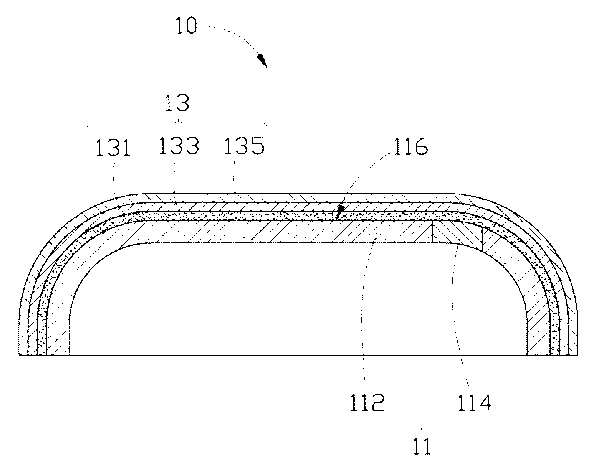

[0012] see figure 1 , the housing 10 of the preferred embodiment of the present invention includes a base 11 and a decorative film 13 formed on the surface of the base 11 .

[0013] The base body 11 is integrally formed by a metal part 112 and a plastic part 114 . When the shell 10 is used as a shell of a mobile phone, the plastic part 114 corresponds to the position of the antenna inside the mobile phone, so that it will not affect the radio frequency function of the mobile phone.

[0014] The decoration film 13 includes a primer layer 131 , a non-conductive vacuum coating layer 133 and a protective paint layer 135 .

[0015] The primer layer 131 is directly formed on the substrate 11 and covers the outer surface 116 jointly formed by the metal part 112 and the plastic part 114 . The primer layer 131 can effectively improve the surface smoothness of the substrate 11, so that the surface of the subsequent non-conductive vacuum coating layer 133 is smooth and has better brigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com