Thermoelectric device and cooling fin integrated thermoelectric assembly

A technology of thermoelectric devices and thermoelectric components, applied in thermoelectric device components, thermoelectric devices, electric solid devices, etc., can solve the problems of reducing thermoelectric performance and production efficiency of thermoelectric components, increasing production costs, difficult to control torque, etc., to improve production Efficiency, Avoidance of Production Cost, Effect of Elimination of Thermal Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

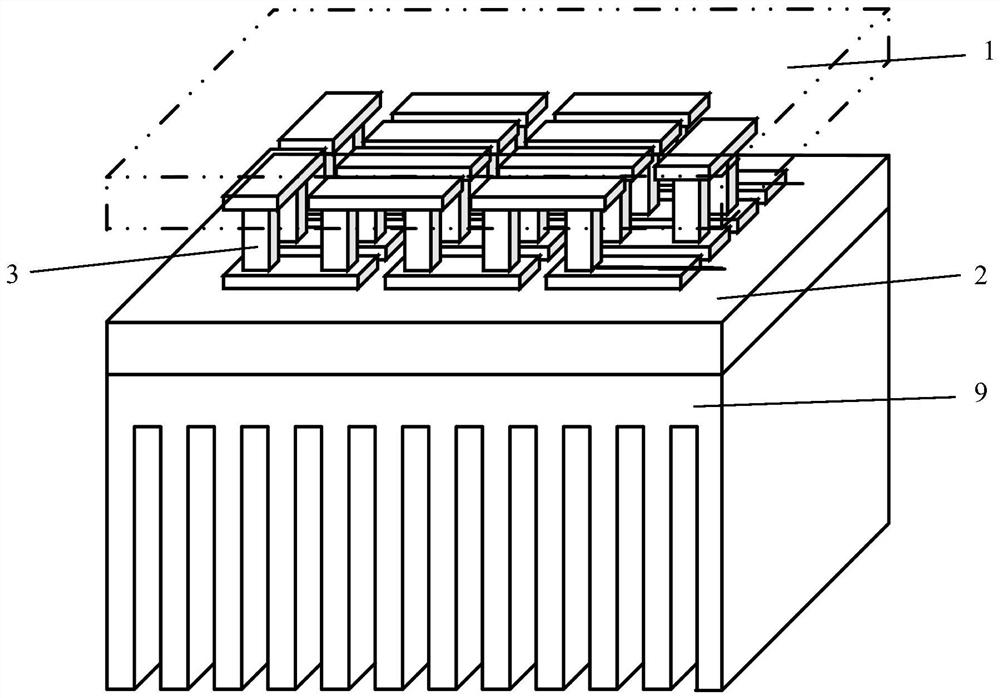

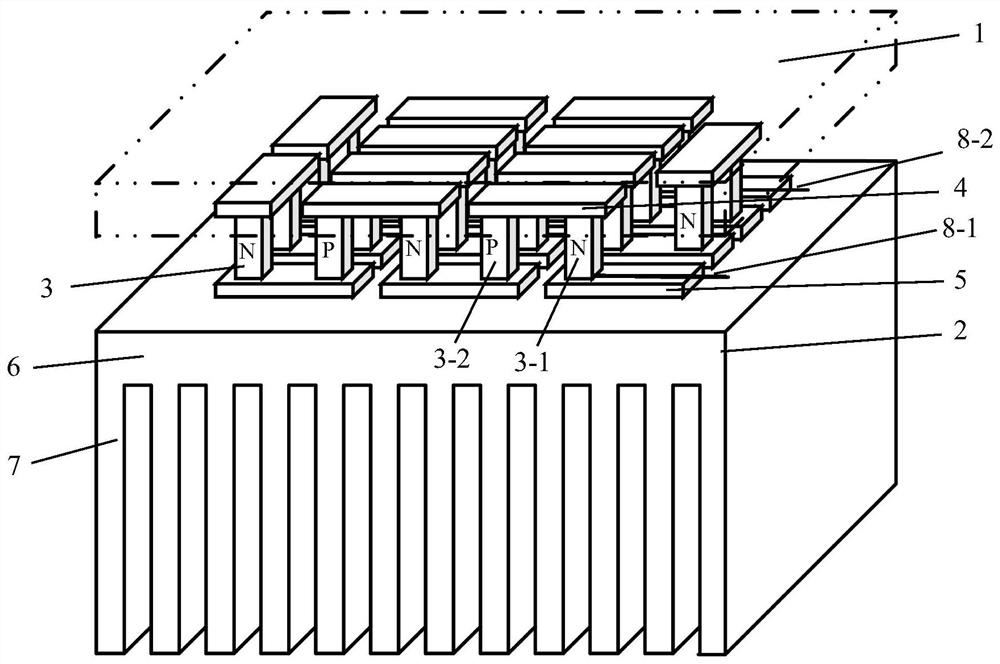

[0027] Such as figure 2 As shown, in embodiment 1, the thermoelectric assembly in which the thermoelectric device and heat sink of the present invention are integrated includes a first ceramic substrate 1, a second ceramic substrate 2, and thermoelectric material grains 3; the first ceramic substrate 1 is welded with The first guide sheet 4, the second guide sheet 5 is welded on the second ceramic substrate 2, the thermoelectric material grain 3 is welded on the first guide sheet 4 at one end, and welded on the other end. On the second guide plate 5; the second ceramic substrate 2 in the first ceramic substrate 1 and the second ceramic substrate 2 is a ceramic substrate with fins, and the ceramic substrate with fins includes integrally formed Ceramic base 6 and cooling fins 7. Wherein, the thermoelectric device may be a thermoelectric refrigeration device or a thermoelectric power generation device. In Embodiment 1, the thermoelectric device is a thermoelectric refrigeratio...

Embodiment 2

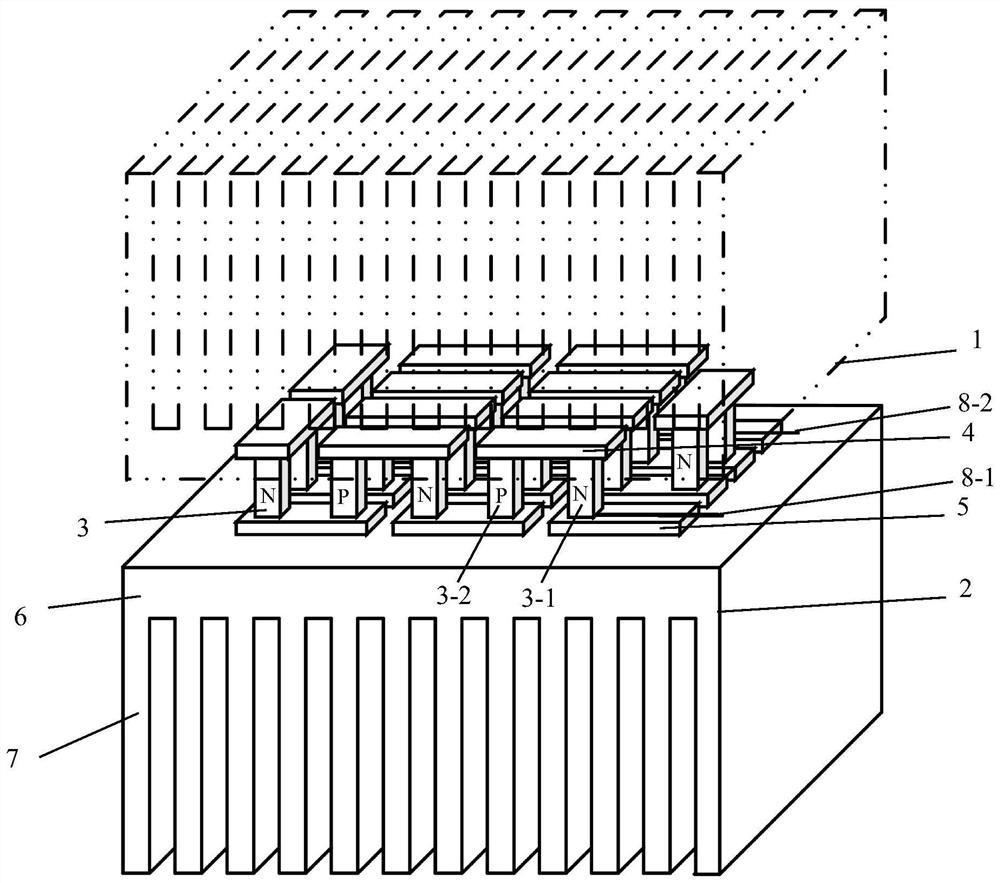

[0041] Such as image 3 As shown, the difference between this embodiment 2 and the embodiment 1 lies in that both the first ceramic substrate 1 and the second ceramic substrate 2 are ceramic substrates with fins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com