Volume adjustable fluid pump

A fluid pump and type-adjusting technology, which is applied to variable displacement pump components, components of a pumping device for elastic fluid, and pumps, etc., can solve the problems of increased manufacturing cost and complex structure in the number of components, and can reduce the number of components. , The effect of improving durability and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

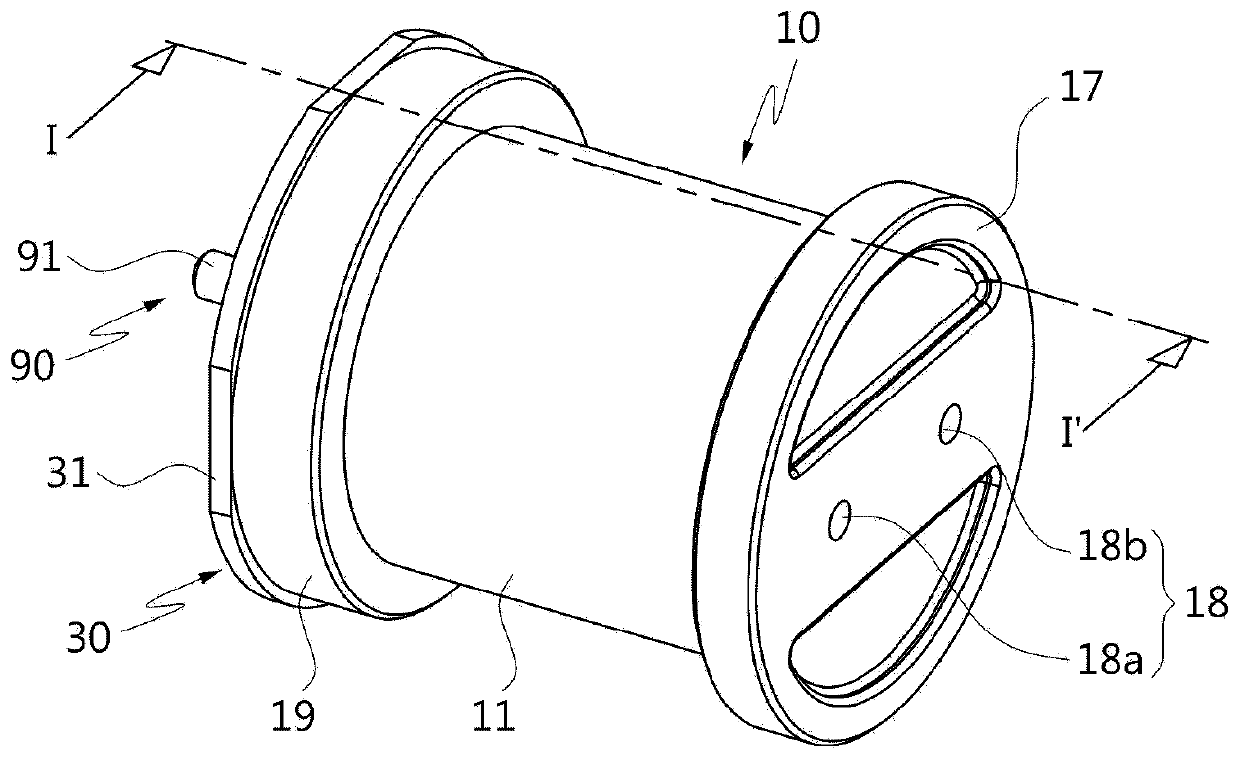

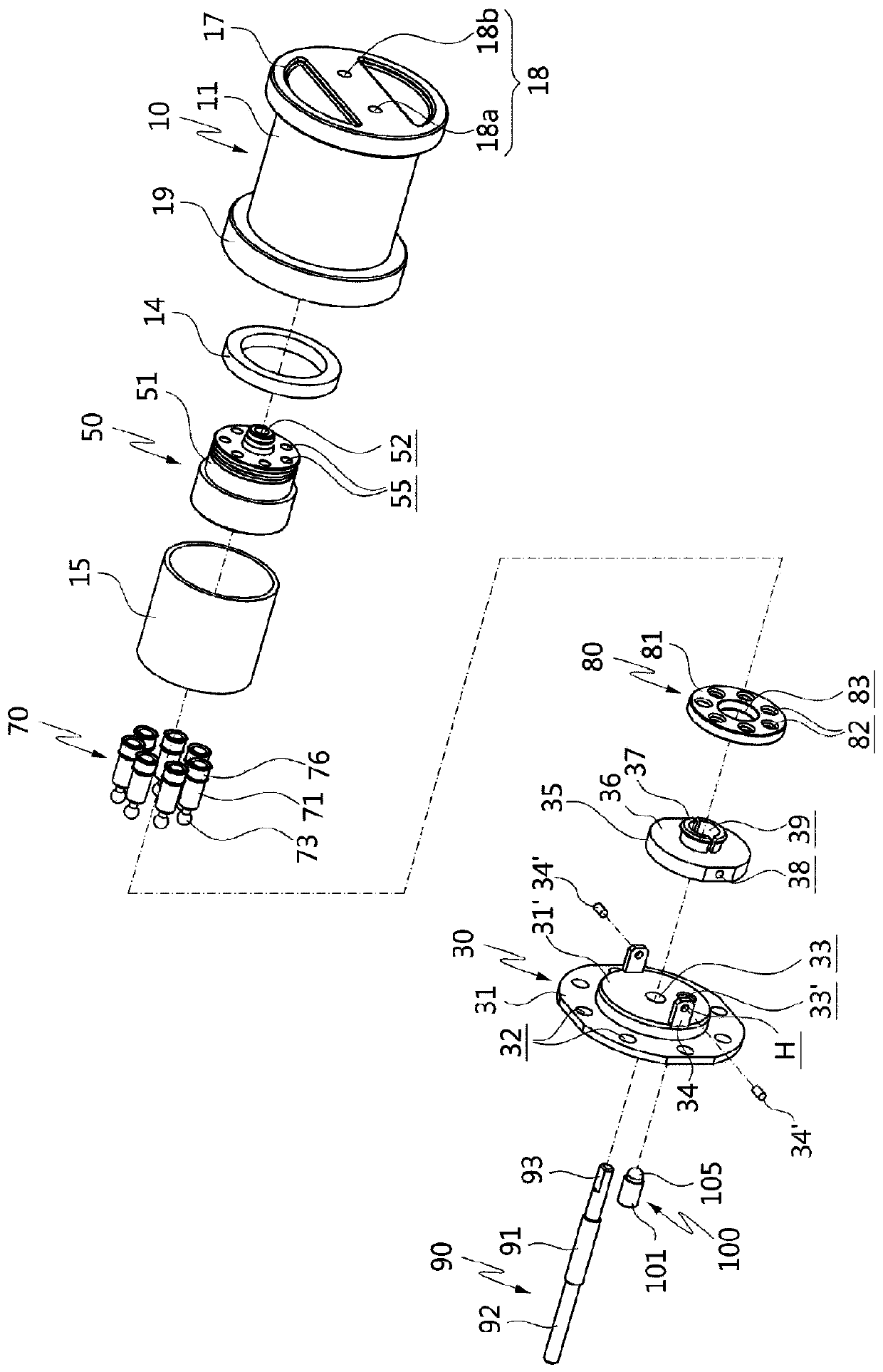

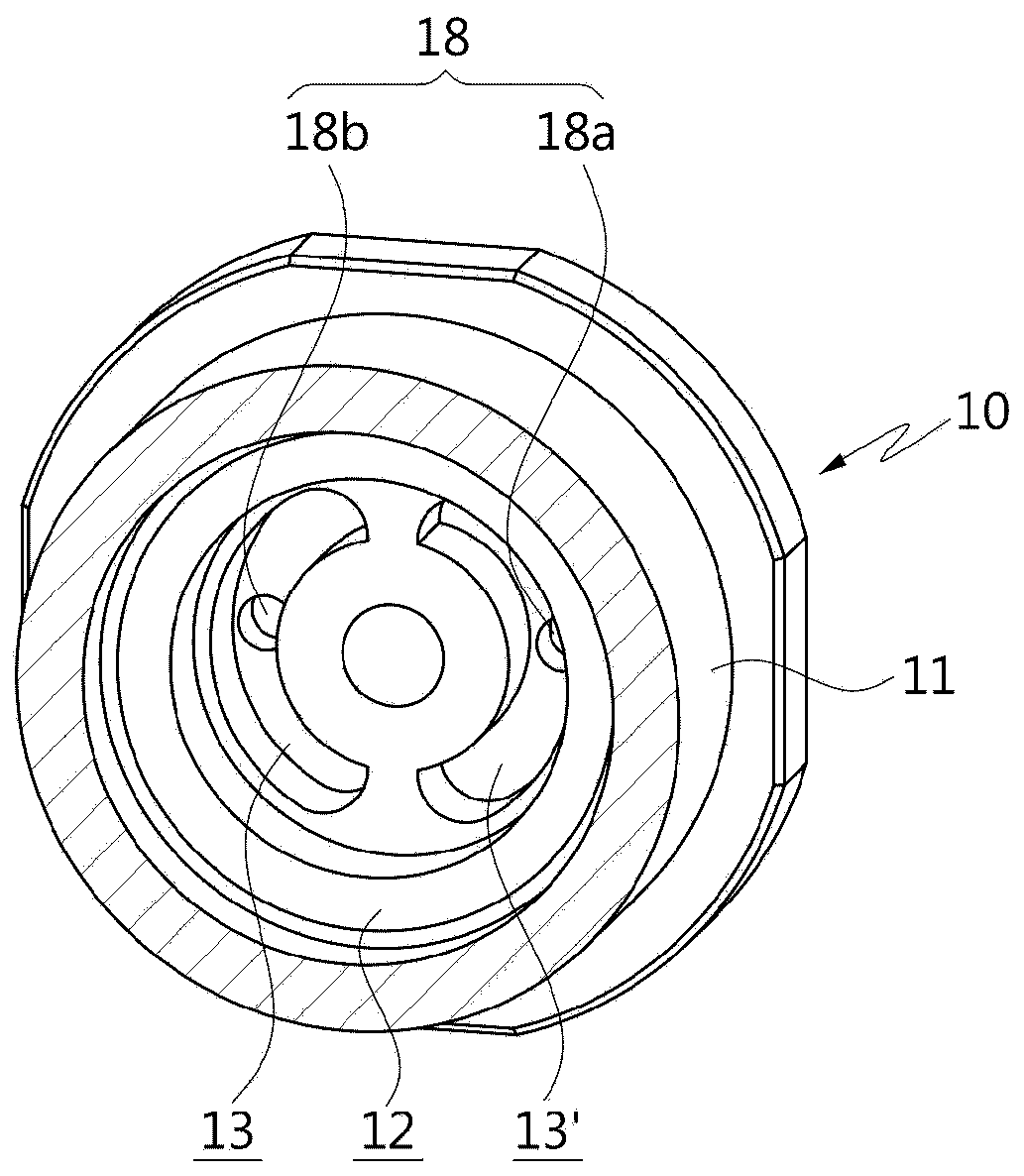

[0076] The present invention relates to a capacity-adjustable fluid pump that uses a motor or an engine to rotate a drive shaft 90 and converts the rotational force of the drive shaft 90 into translational motion of a piston to form oil pressure or water pressure. In particular, in the present invention, the inclination angle of the swash plate 35 can be adjusted by the inclination adjustment unit 100 having a simple structure. Furthermore, the swash plate 35 is fixed in a non-rotatable manner, while the stop ring 80 is independently rotatable with respect to the swash plate 35 and is rotatably fixed to the swash plate 35 . Thereby, the retaining ring 80 can be rotated while maintaining a certain inclination angle, thereby preventing the retaining ring 80 from tilting or shaking during the rotation. Next, a specific configuration of the present invention will be described in detail.

[0077] Such as figure 1 As shown, the main structure of the present invention is constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com