Environmental-protecting shoes for preventing prick and fungus

An environmentally friendly and anti-stab technology, applied in footwear, shoe soles, clothing, etc., can solve the problems of environmental pollution, shoe soles are not easy to degrade, etc., and achieve the effects of simple production process, superior processing performance, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

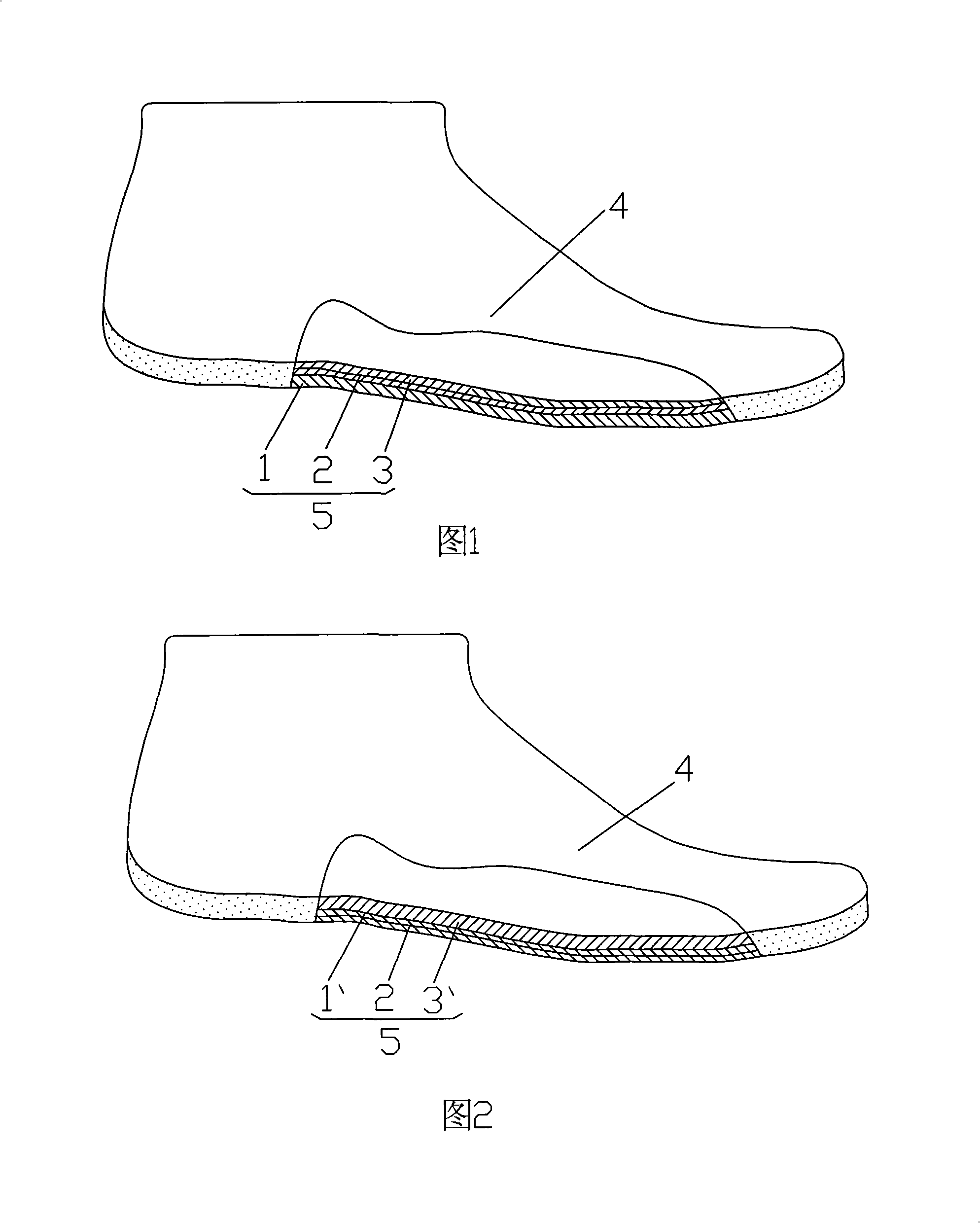

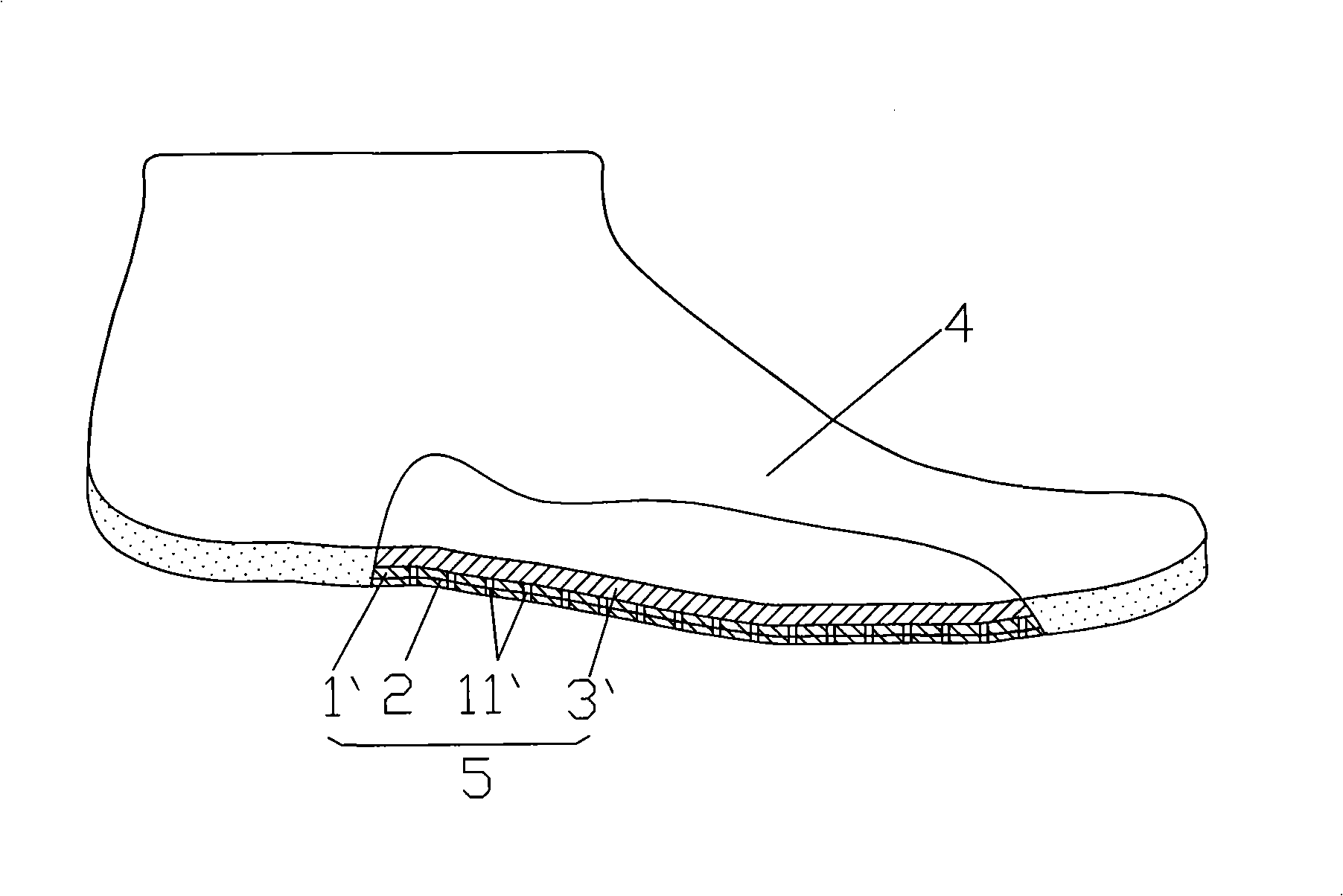

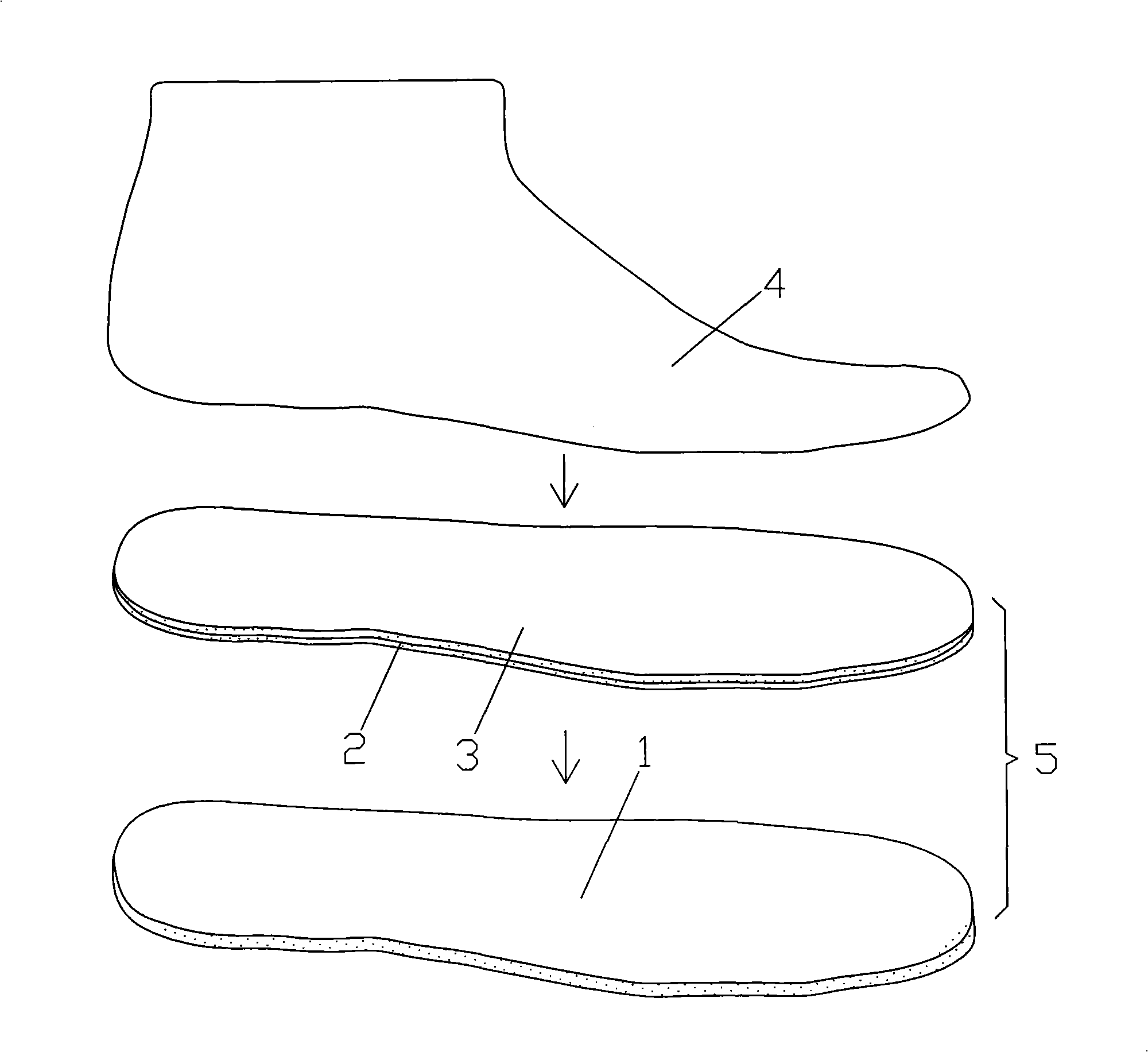

[0023] Figure 1, Figure 2 and image 3 As shown, the anti-stab and anti-mold environment-friendly shoes of the present invention include a vamp 4 and a sole 5, and the vamp 4 is fixed on the sole 5, wherein the sole 5 includes a matrix and a thin metal layer 2, and the vamp 4 is fixed on the sole 5. The thin metal layer 2 is embedded in the matrix and integrally formed with the matrix. The matrix is a thermoplastic elastomer. The matrix made of thermoplastic elastomer has excellent processing performance, no need for vulcanization, and the production process is simple, and the The substrate can be recycled and reused, the combustion is non-toxic, and has good environmental protection performance. More specifically as follows:

[0024] Figure 1 and Figure 4 As shown, the first embodiment of the anti-stab and anti-mildew environment-friendly shoes of the present invention, the anti-stab and anti-mold environment-friendly shoes comprise vamp 4, midsole 3 and outsole 1, and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com