Structural part with like diamond array and preparation method thereof

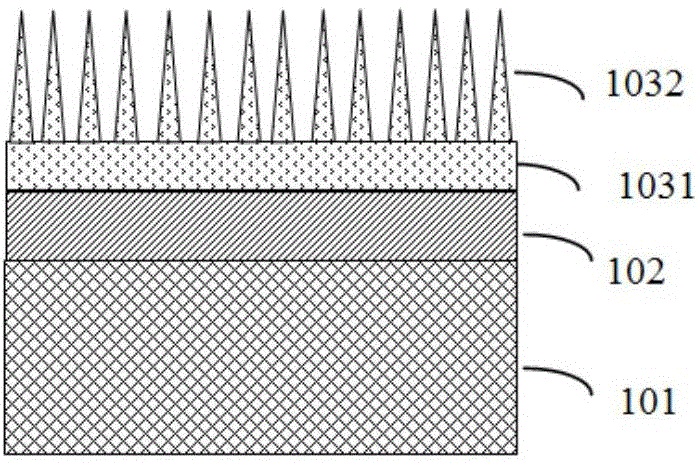

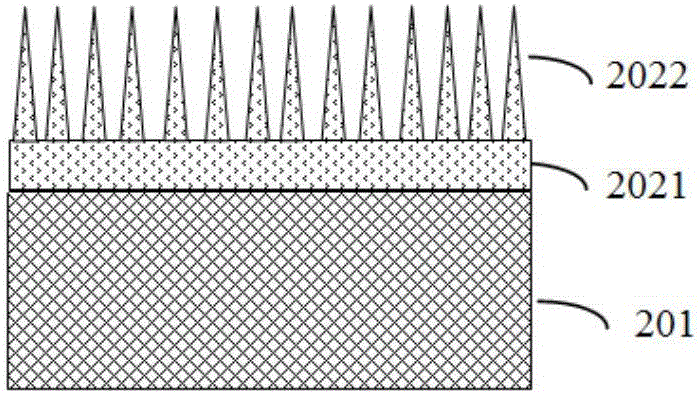

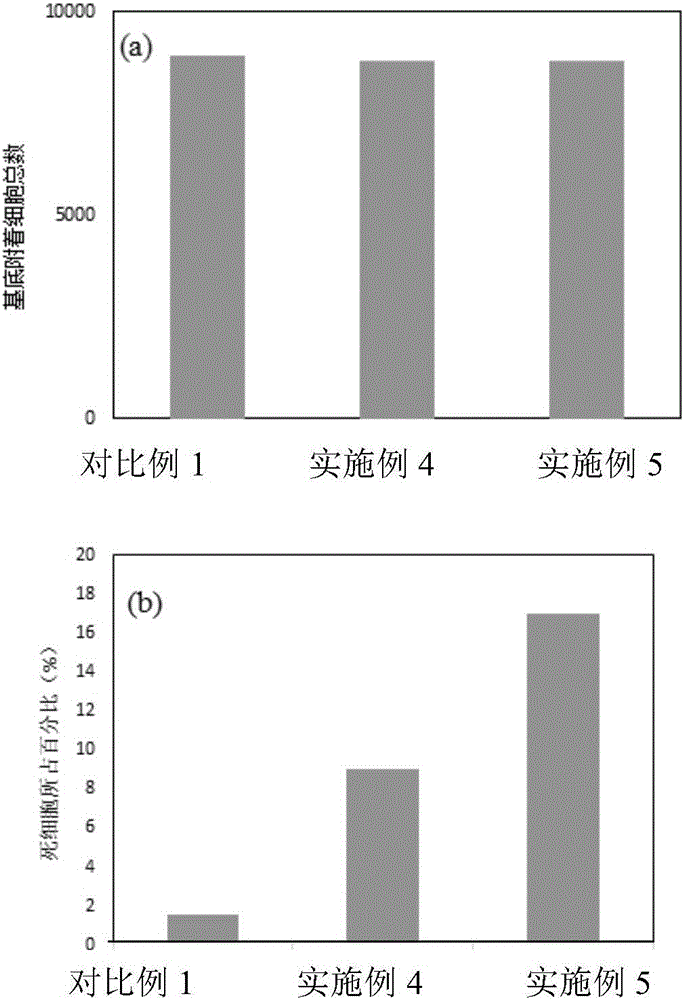

A technology of diamond-like structural parts, applied in the field of structural parts with diamond-like arrays and its preparation, can solve the problems of no antibacterial performance and weak bactericidal performance, and achieve the prevention of bacterial infection, significant antibacterial performance, and beneficial human health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing a structural member having a diamond-like array, comprising:

[0049] (1) Substrate pretreatment:

[0050] Cobalt-chromium alloy is provided as the substrate. First, the substrate is ultrasonically cleaned with distilled water for 10 minutes, then ultrasonically cleaned with acetone and absolute ethanol for 20 minutes, and then the substrate is dried with nitrogen and placed in a blast drying oven at 100 ° C. ;

[0051] Place the above-mentioned substrate in the vacuum chamber of the multifunctional ion coating equipment (V-Tech MF610 / 610), and first evacuate the vacuum chamber to a background vacuum degree of 5.0×10 -3 Pa, open the main valve of the argon cylinder, the pressure reducing valve, the ion source valve, the arc valve and the target valve, and the mass flow meter feed argon gas into the vacuum chamber to perform glow cleaning on the substrate, wherein the conditions for glow cleaning are: argon The gas flow rate is 300sccm, the worki...

Embodiment 2

[0056] A method for preparing a structural member having a diamond-like array, comprising:

[0057] (1) Substrate pretreatment:

[0058] Provide a polyetheretherketone (PEEK) substrate as a substrate. First, use distilled water to ultrasonically clean the substrate for 10 minutes, then use acetone and absolute ethanol to ultrasonically clean it for 20 minutes, and then blow dry the substrate with nitrogen, and put it in the air to dry. Dry in oven at 80°C;

[0059] Place the above substrate in a multifunctional ion coating equipment (V-Tech MF610 / 610), and vacuumize to 5.0×10 - 3 Pa, open the main valve of the argon cylinder, the pressure reducing valve, the ion source valve, the arc valve, the target valve and the mass flow meter pass argon gas into the vacuum chamber to perform glow cleaning on the substrate. Argon gas is introduced into the room, the flow rate of argon gas is 400sccm, the working pressure is 1.4Pa, and the substrate bias voltage is -500V. The substrate i...

Embodiment 3

[0065] A method for preparing a structural member having a diamond-like array, comprising:

[0066] (1) Substrate pretreatment:

[0067] Provide a Ni-Ti alloy as a substrate. First, use distilled water to ultrasonically clean the substrate for 10 minutes, then use acetone and absolute ethanol to ultrasonically clean it for 20 minutes, then dry the substrate with nitrogen, and put it in a blast drying oven at 120 ° C. drying;

[0068] Place the above-mentioned substrate in the multifunctional ion coating equipment (V-Tech MF610 / 610), and the background vacuum degree is 5.0×10 -3 Under the condition of Pa, open the main valve of the argon cylinder, the pressure reducing valve, the ion source valve, the arc valve and the target valve, and the mass flow meter pass argon gas into the vacuum chamber to perform glow cleaning on the substrate. Among them, the conditions of glow cleaning For: feed argon gas into the vacuum chamber, the flow rate of argon gas is 500 sccm, the working ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com