Shell and manufacturing method thereof

A manufacturing method and shell technology, which are applied to metal shells, electrical equipment shells/cabinets/drawers, decorative arts, etc., can solve the problems of no three-dimensional effect, easy to be worn, and low powder coating adhesion, and achieve strong three-dimensionality. Sensitive, not easy to wear, and quick to modify the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

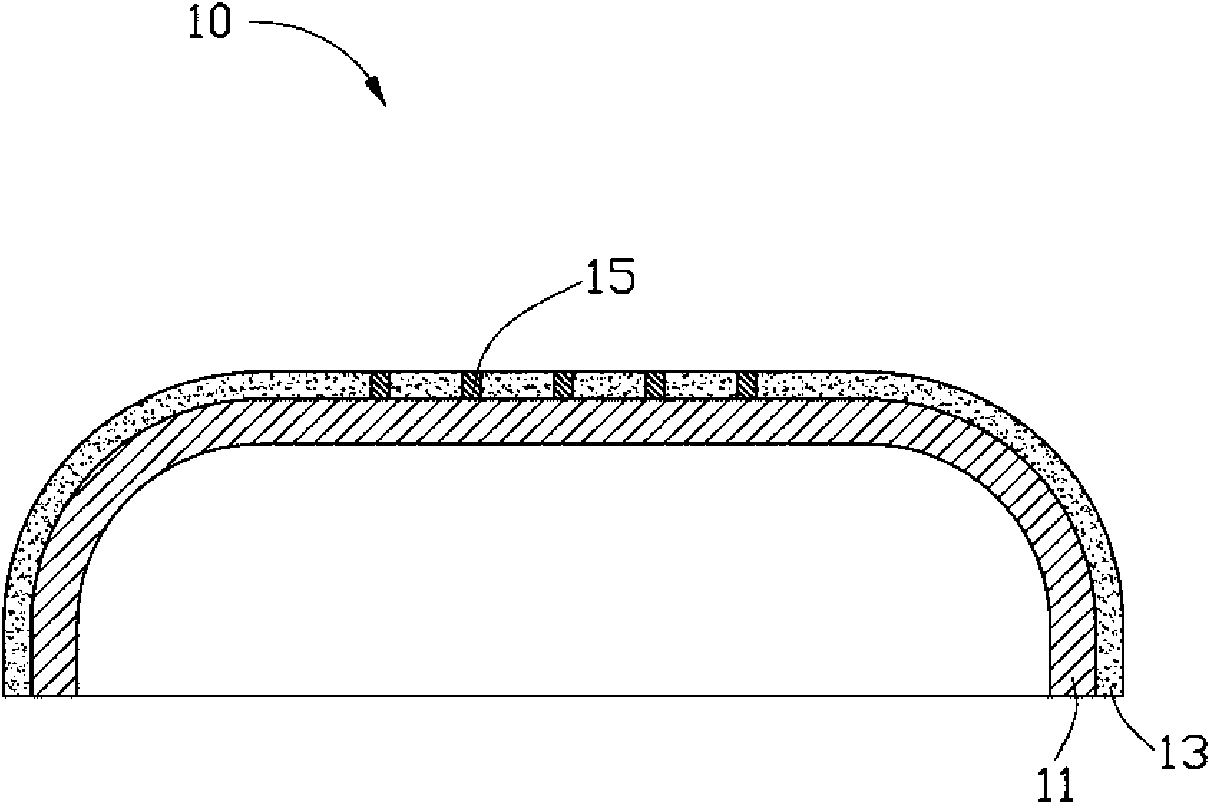

[0013] The casing 10 of the preferred embodiment of the present invention is as figure 1 As shown, it includes a substrate 11 , a powder coating 13 formed on the substrate 11 and a pattern layer 15 formed in the powder coating 13 .

[0014] The base 11 is a metal base, and the material for making the base 11 can be aluminum or aluminum alloy, magnesium or magnesium alloy, titanium or titanium alloy, and the like.

[0015] The powder coating 13 is formed by spraying on a surface of the substrate 11 by means of electrostatic powder spraying. The paint forming the powder coating 13 can be polyurethane resin powder or epoxy resin powder. The thickness of the powder coating 13 is between 60-90 μm. Grooves are formed on the powder coating 13, and the grooves can be formed by laser etching. The texture of the groove is set as a product's trademark or other decorative patterns, and the depth of the groove can be equivalent to the thickness of the powder coating 13 .

[0016] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com