Multiscale prediction method for mechanical property of woven composite material

A technology of composite materials and prediction methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low calculation accuracy, poor versatility, and low calculation efficiency, and achieve high calculation efficiency and reduce The effect of trial volume and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

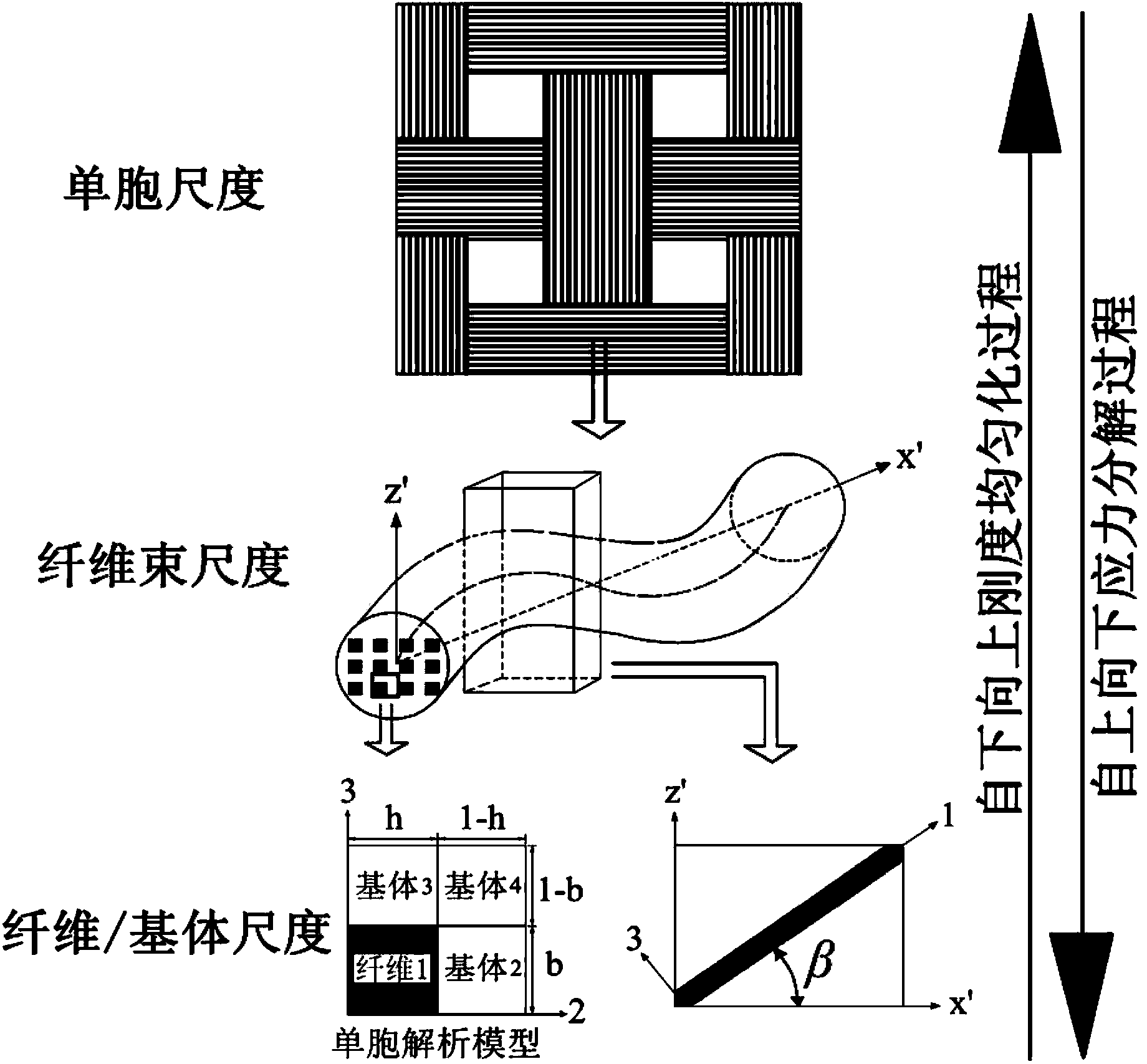

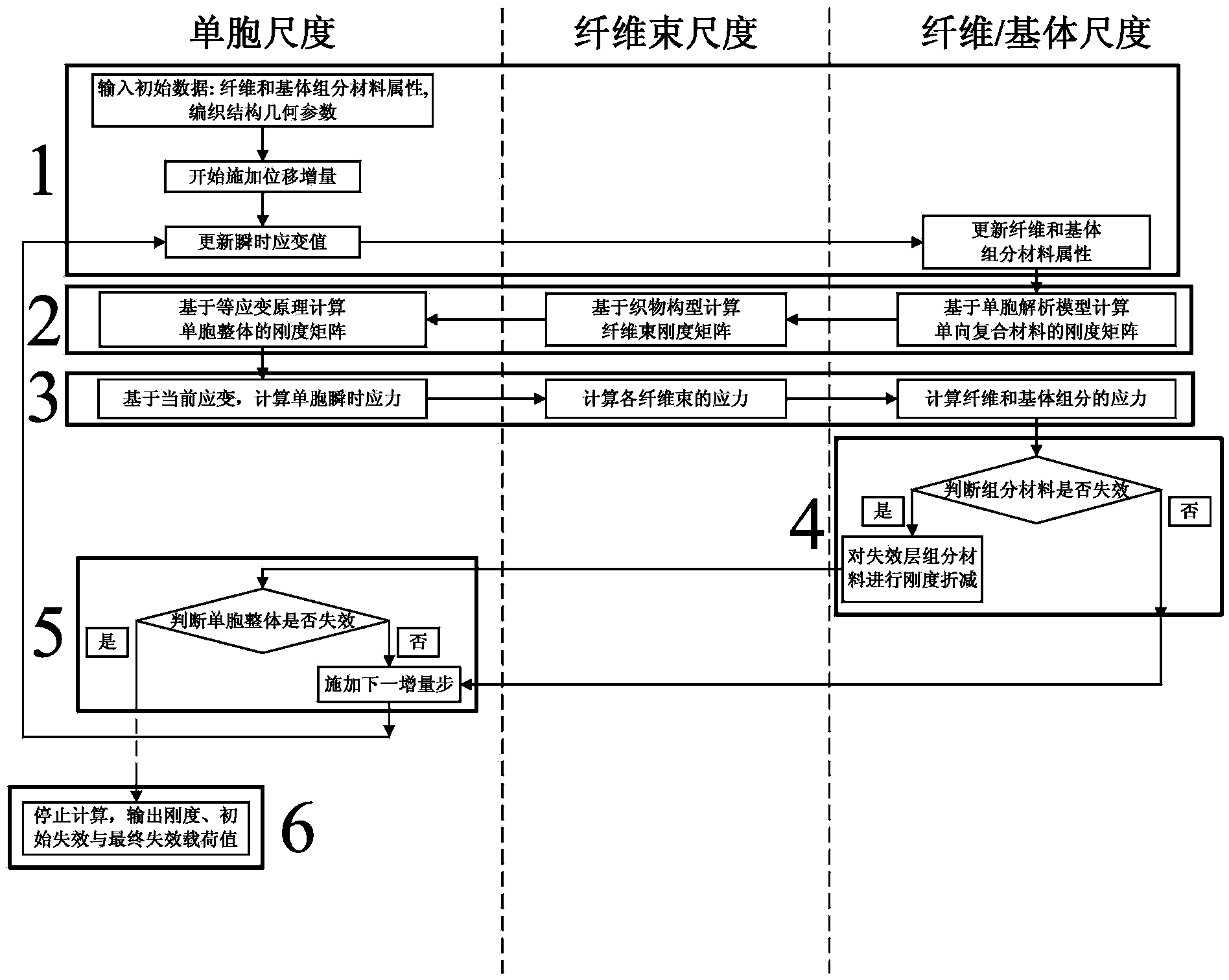

[0035] Such as figure 1 As shown, the method of the present invention mainly considers fiber / matrix scale, fiber bundle scale and unit cell scale. The present invention first obtains the stiffness of the braided composite material according to the bottom-up homogenization method, and then constructs a multi-scale correlation matrix, distributes the macro stress to the local components according to the top-down stress decomposition method, and adopts the fiber / matrix scale The failure analysis is performed on the following meso-strength criterion, and the strength of the braided composite is finally calculated.

[0036] The bottom-up homogenization method considers the fiber / matrix scale, fiber bundle scale, and unit cell scale in turn. The fiber / matrix scale is a unidirectional fiber-reinforced composite material. The sub-cells are divided based on the unit cell analytical model, and then the stiffness matrix of the unidirectional fiber-reinforced composite material is obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com