Competitive failure analysis method for wear degradation and functional degradation of aircraft lock mechanism components

A technology of competition failure and analysis method, which is applied in the field of reliability analysis of aircraft lock mechanism components, and can solve the problems of low reliability of analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

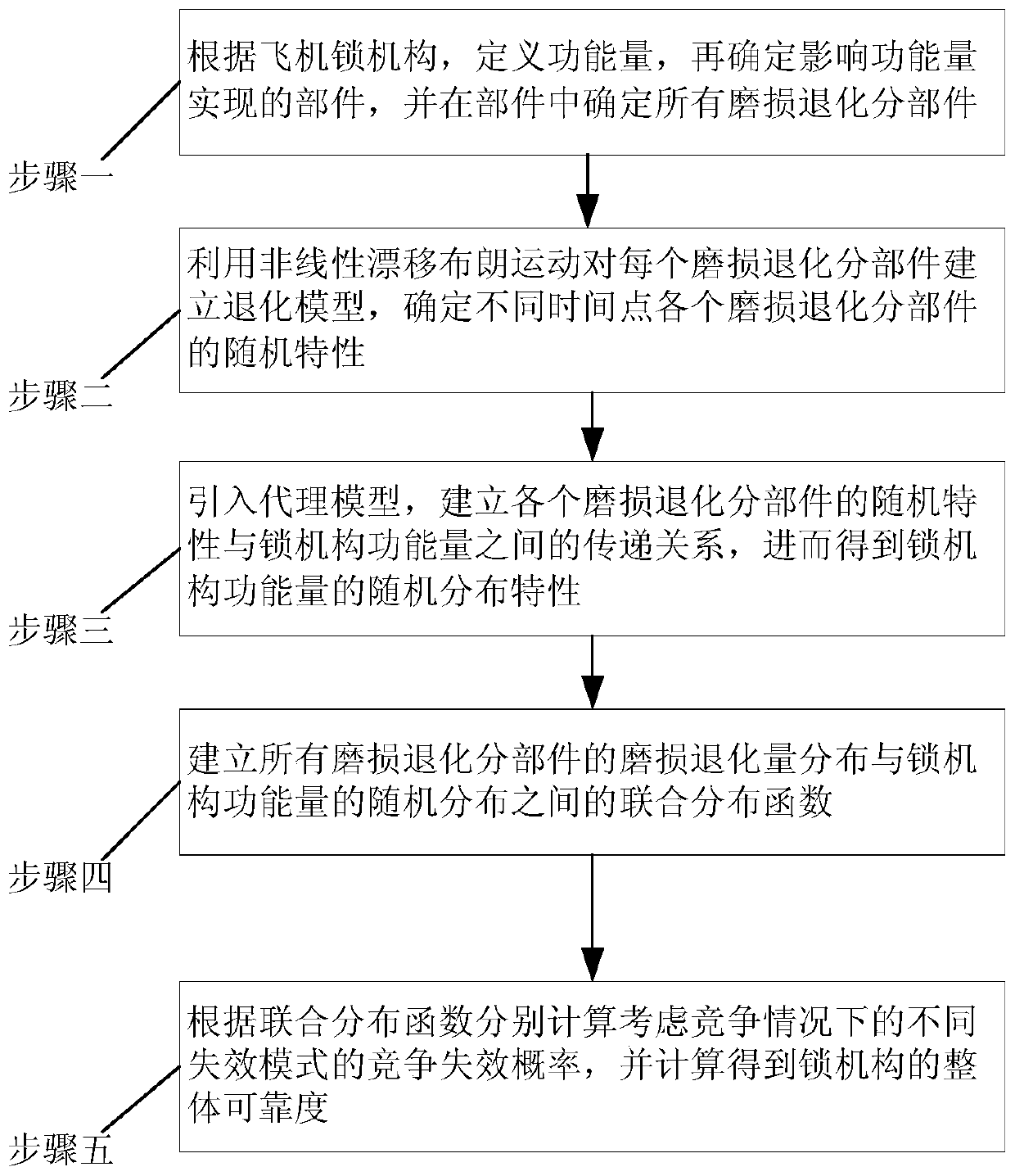

[0022] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the aircraft lock mechanism component wear degradation and functional degradation competition failure analysis method described in this embodiment, it comprises the following steps:

[0023] Step 1: According to the aircraft lock mechanism, define the functional energy, then determine the components that affect the realization of the functional energy, and determine all the wear and degradation sub-components in the components;

[0024] Step 2: use nonlinear drift Brownian motion to establish a degradation model for each wear degradation sub-component, and determine the random characteristics of each wear degradation sub-component at different time points;

[0025] Step 3: Introduce a proxy model to establish the transfer relationship between the random characteristics of each wear and degradation component and the functional energy of the lock mechanism, and then obtain the r...

specific Embodiment approach 2

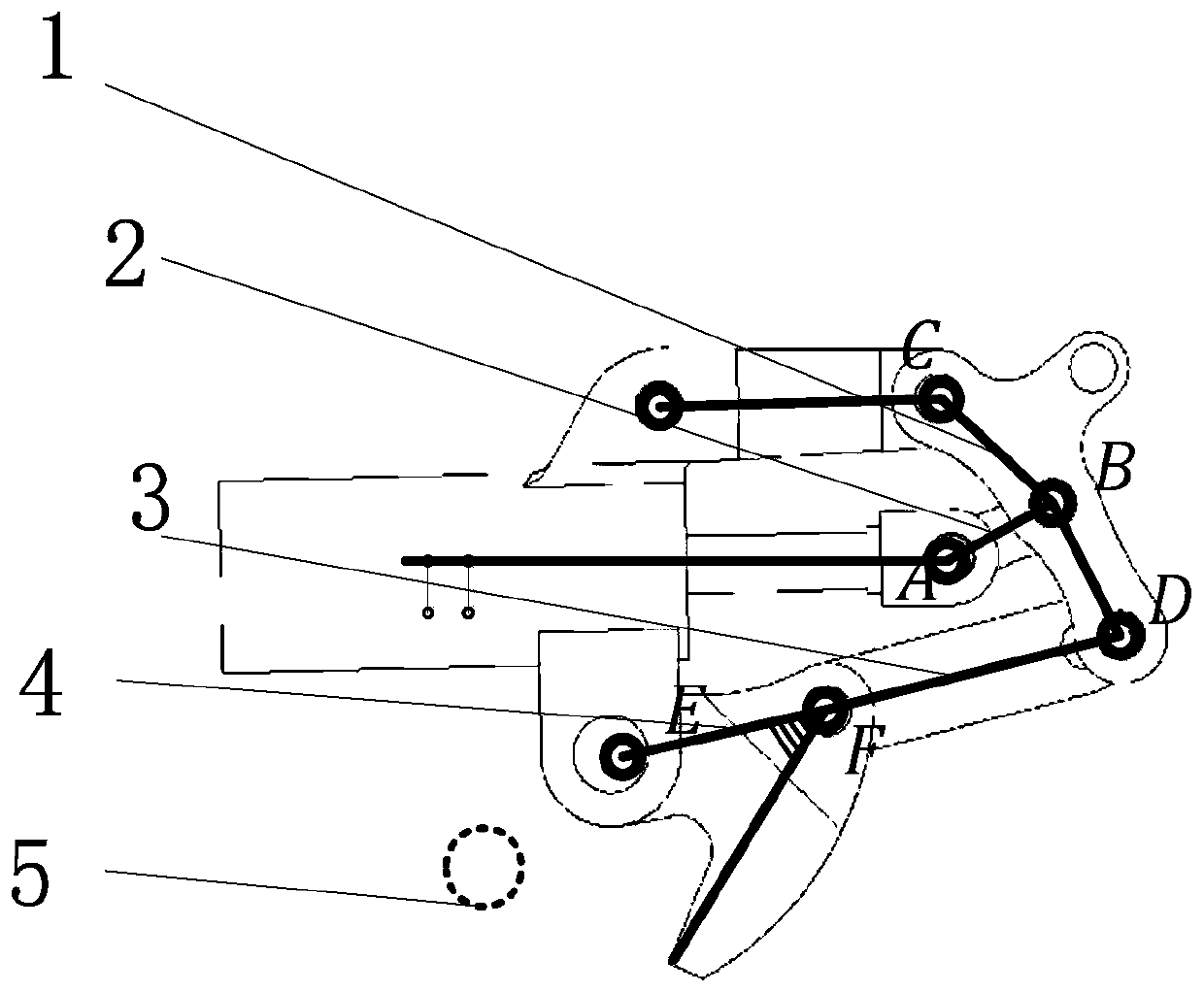

[0028] Specific implementation mode two: the following combination Figure 1 to Figure 7 Illustrate this embodiment, and this embodiment will further explain Embodiment 1. In step 1, the aircraft lock mechanism is an aircraft door upper lock mechanism, and the aircraft door upper lock mechanism consists of rocker arm 1, rocker middle link 2, The lower link 3 of the rocker arm, the lock hook 4 and the lock ring 5 are composed, and the distance from the top end of the hook end of the lock hook 4 to the center of the lock ring 5 is defined as the kinetic energy, and one end of the link 2 in the rocker arm is connected with the center of the rocker arm 1 Point connection, determine that the hinge A through which the other end of the connecting rod 2 in the rocker arm is connected to the fixed part is a wear and degradation sub-component;

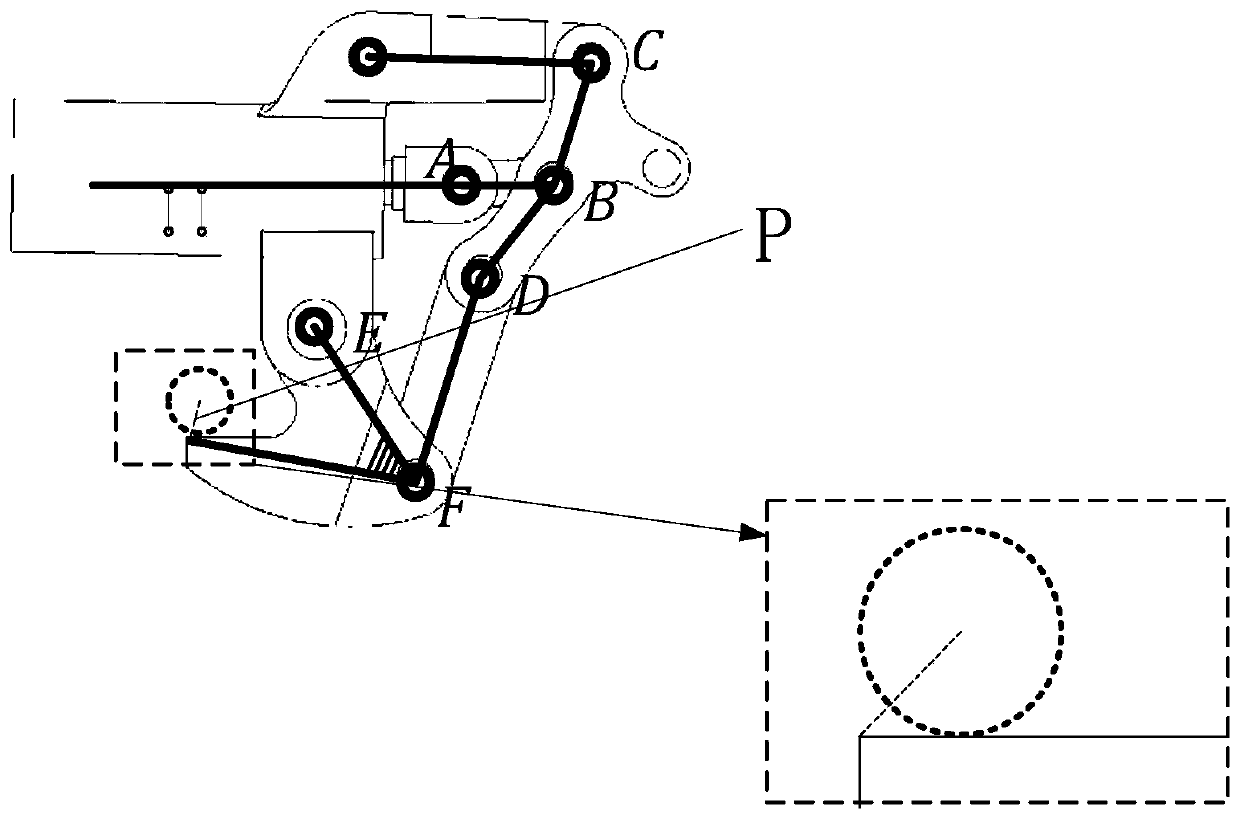

[0029] figure 2 and image 3 The working process of the lock mechanism is briefly indicated in the figure. The function of the upper lock me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com