High thermal conductivity glass reinforced plastic ground heating floor

A glass fiber reinforced plastic, high thermal conductivity technology, used in buildings, building structures, floors, etc., can solve the problems of FRP heat dissipation effect staying, low thermal conductivity of FRP, etc., to reduce heat transfer medium resistance, good thermal conductivity, and smooth appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is further described:

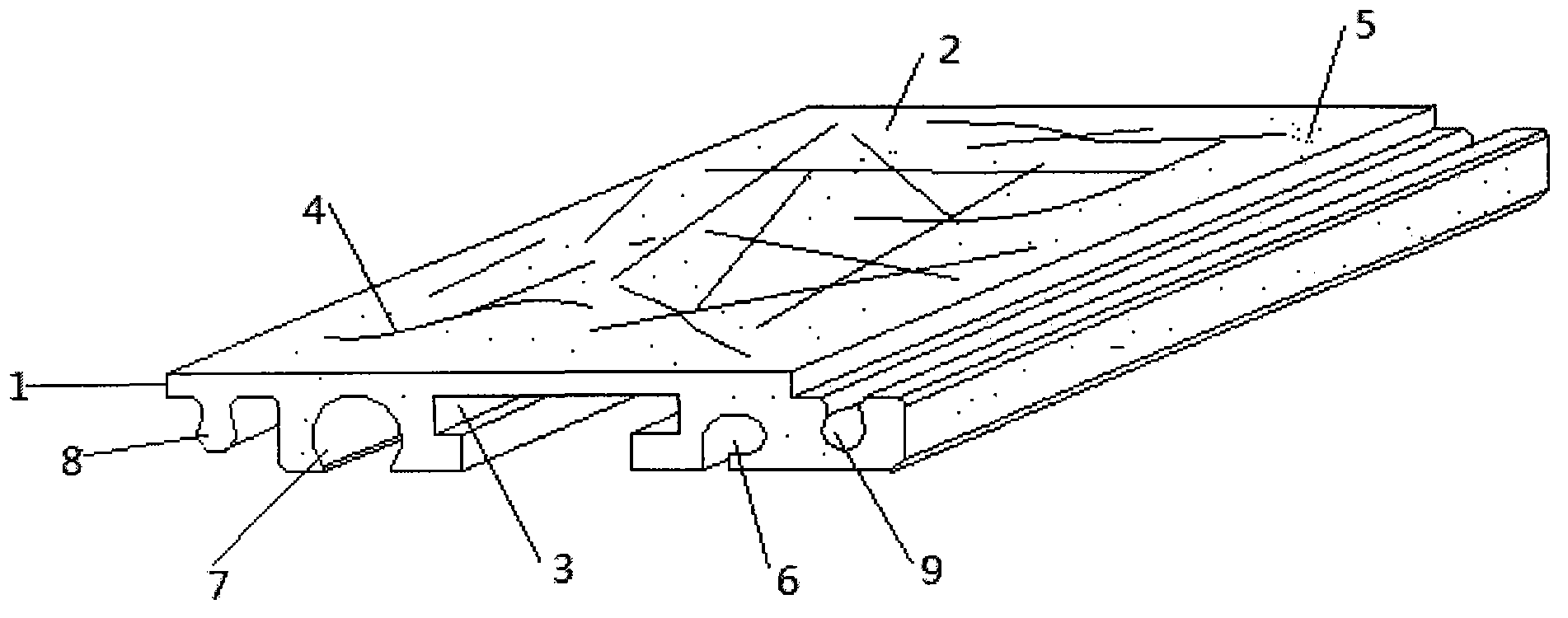

[0013] like figure 1 As shown, the floor 1 includes a floor base 2, the floor base 2 is made of high thermal conductivity FRP, and there are concave patterns on the floor base 2, and the concave patterns can be circular grooves 6, 7 or rectangular grooves 3 The circular grooves 6 and 7 are used for laying pipelines, and the rectangular groove 3 can accommodate the floor heating heating pipes that communicate with each other. The interior of the floor matrix 2 is thermally conductive carbon fiber 4 and thermally conductive metal powder 5, which are cured and connected with resin. Glass fiber can also be added to increase the mechanical strength, but adding glass fiber will reduce the thermal conductivity. Fillers can also be added to reduce the application of resin. In actual production, the ratio of each component is flexibly adjusted according to the required mechanical prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com