Bullet impact method for testing coating/ thin film basal body interface bond strength

A technology of interfacial bonding strength and impact method, which is applied in the field of coating/film, can solve the problems of inability to evaluate the interface bonding performance of strongly bonded coating/film-substrate, high production requirements, low load level, etc., to achieve clear models and reliable The effect of strong operability and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

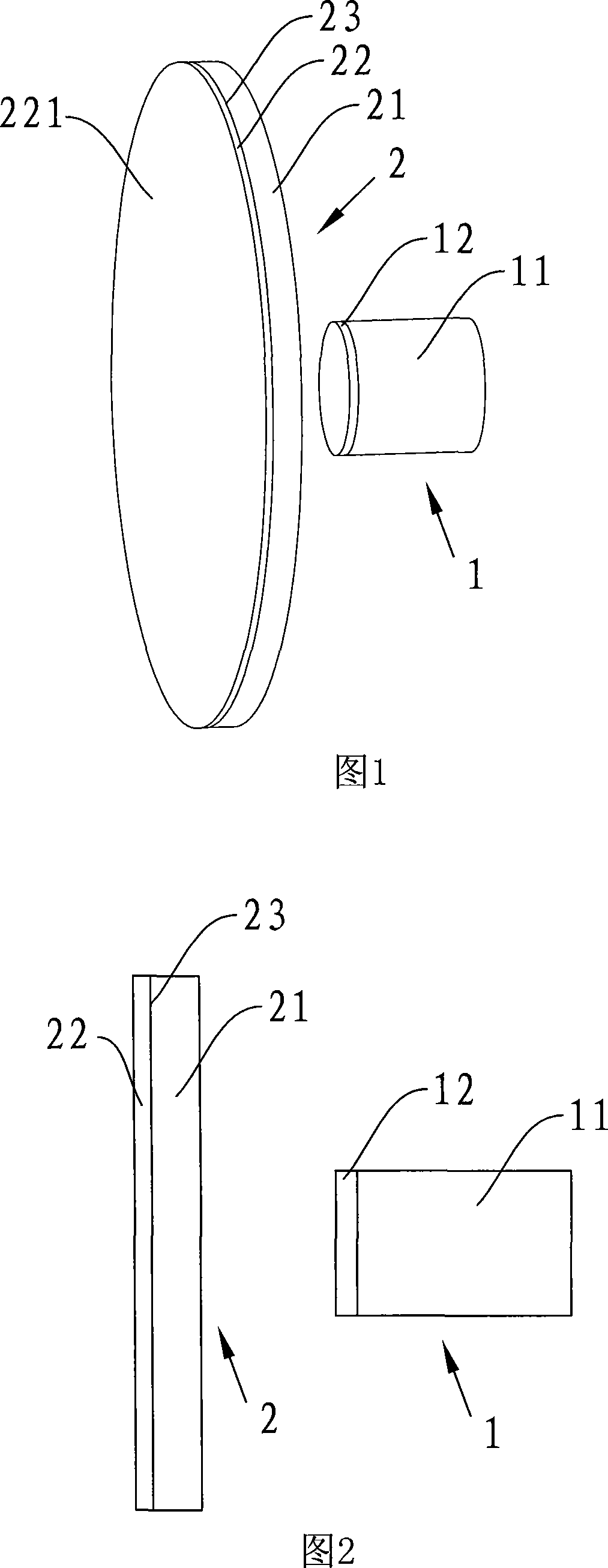

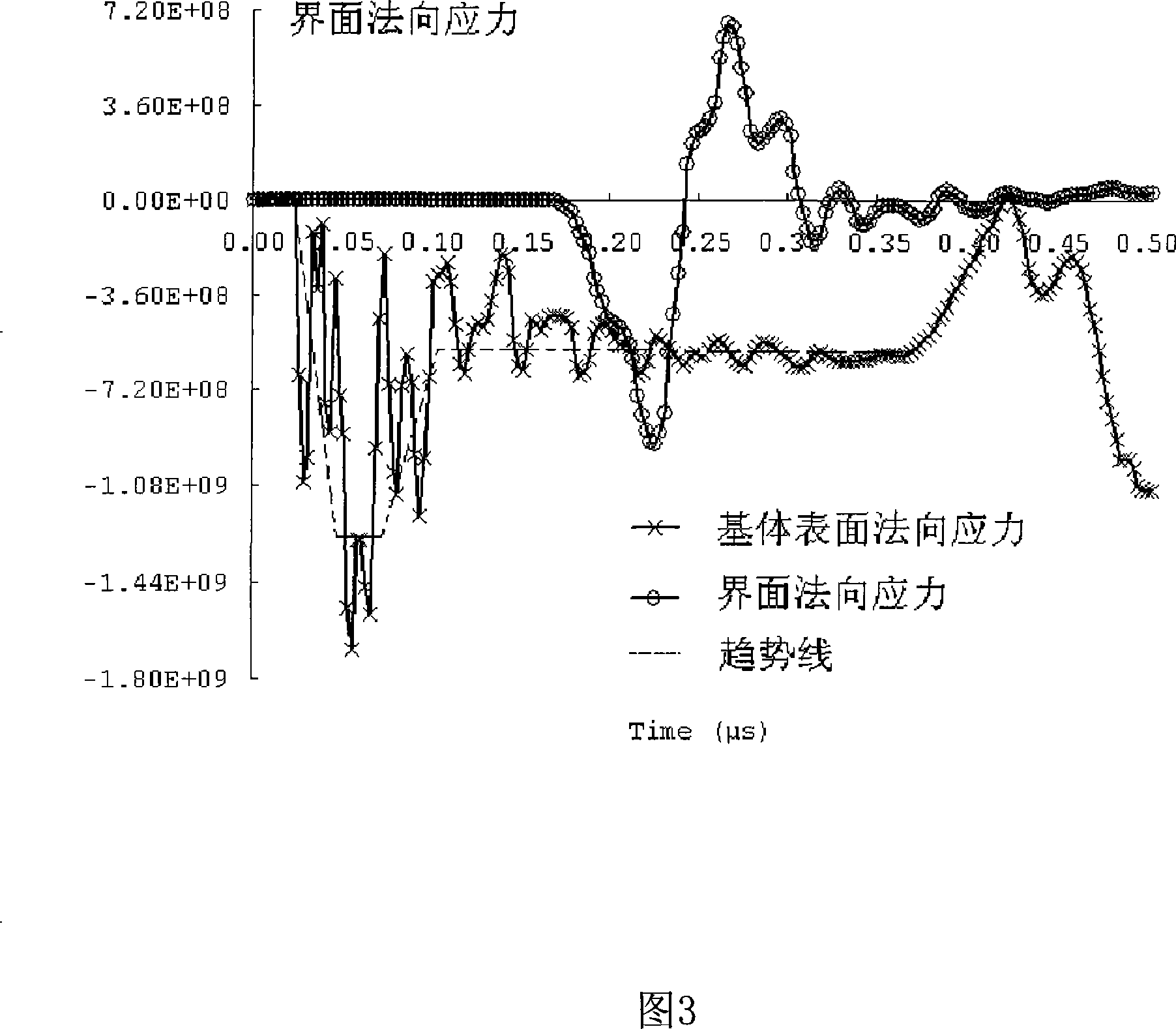

[0023] Referring to Fig. 1 and Fig. 2, the projectile impact method based on spalling effect that the inventor proposes, basic principle is to use the lower material (as plastics) of acoustic impedance as cylindrical projectile 1, by cylindrical projectile matrix 11 and plating The shot coating 12 on the front face of the shot base 11 is composed, and the acoustic impedance of the shot coating 12 is close to that of the sample base 21 .

[0024]

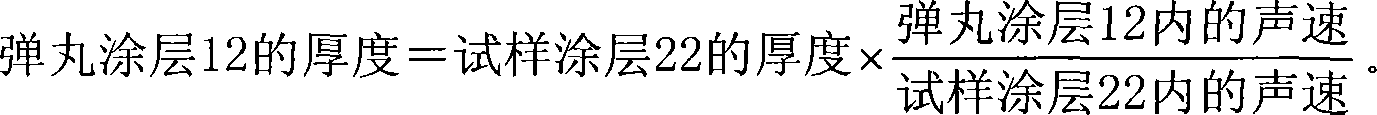

[0025] The sample 2 is fixed on the bracket, and the projectile 1 is launched by a projectile launching device, such as an air gun, a ballistic gun or a gas cannon, so that the projectile 1 moves at a certain speed V along the vertical direction of the sample. 0 The surface of the substrate 21 of the flat sample 2 is impacted, and a compressive stress wave is generated. The stress wave propagates from the impacted part on the substrate to the outer free surface 221 of the coating / film and is reflected, and the reflected wave and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com