Heterogeneous layered mineralized coating on surface of medical implant and preparation method thereof

An implant and heterogeneous technology, applied in coatings, prostheses, medical science, etc., can solve problems such as less research on the distribution of coating components, and achieve the effect of easy promotion and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

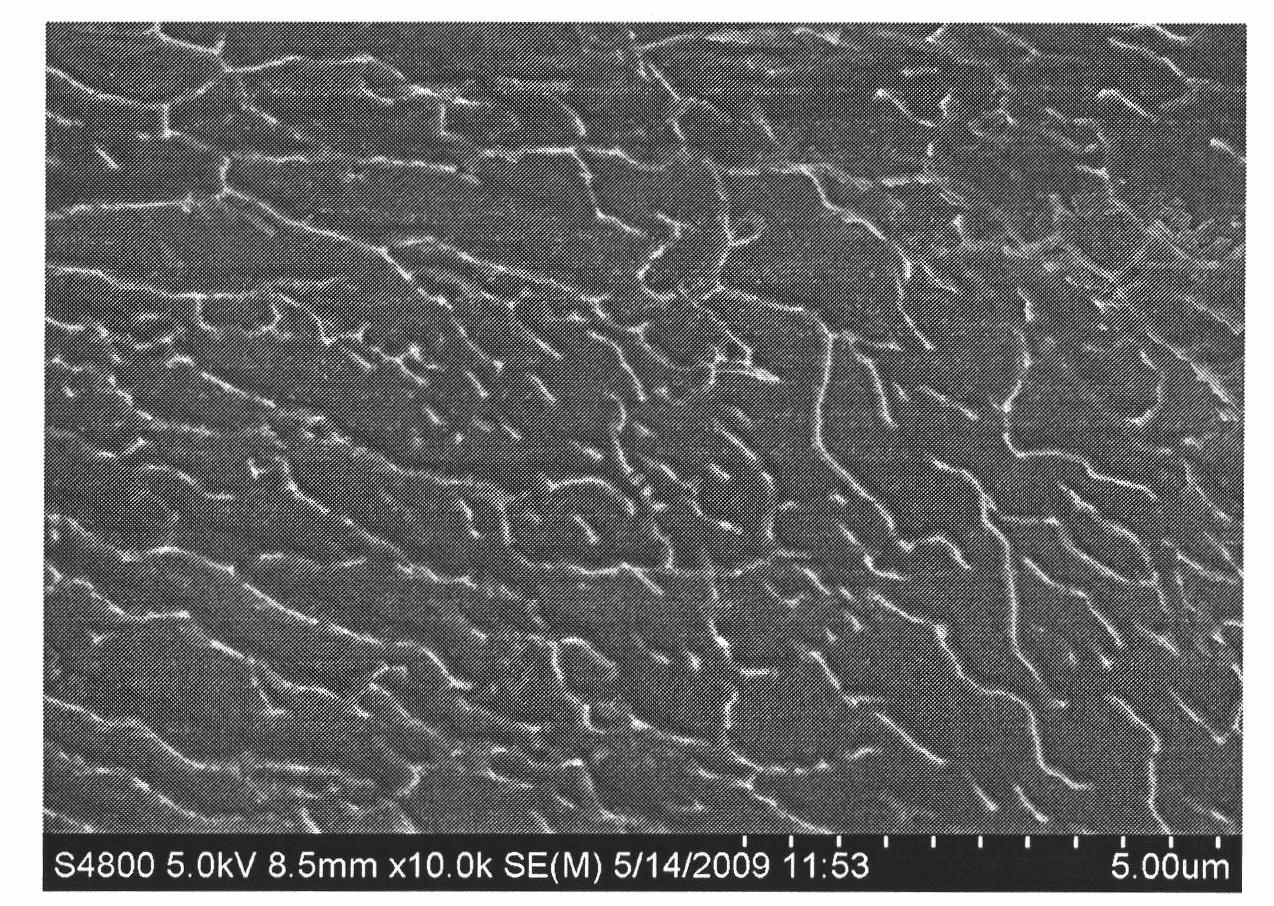

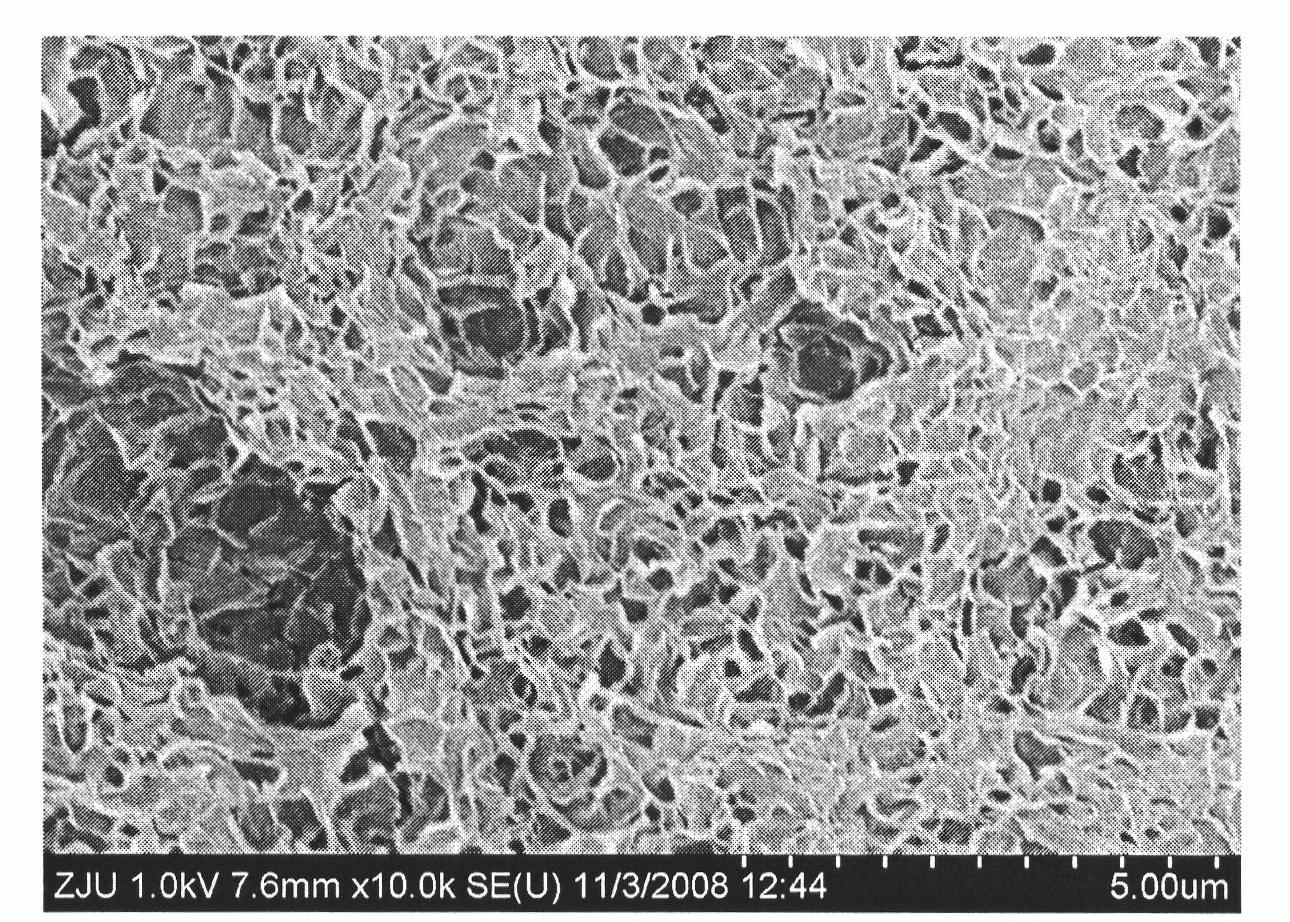

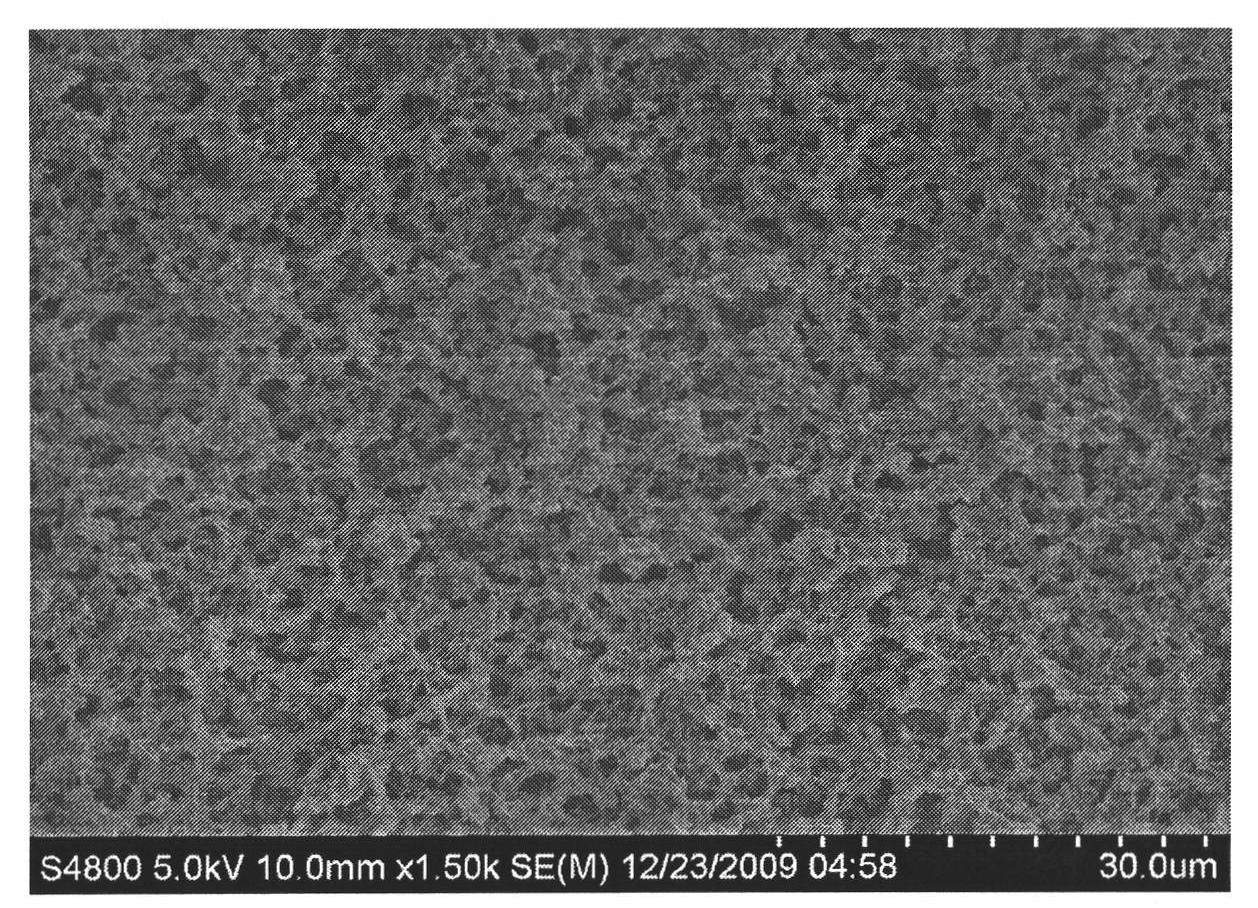

[0031] Chitosan was dissolved in dilute hydrochloric acid to form a chitosan acid solution with a concentration of 1.25 g / L. Dissolve collagen in dilute hydrochloric acid to form a collagen acid solution with a concentration of 1.25 g / L. Ca(NO 3 ) 2 ·6H 2 O was dissolved in distilled water to form a calcium salt solution with a calcium concentration of 0.2M. Put (NH 4 ) 2 HPO 4 Dissolve in distilled water and stir to dissolve to form a phosphate solution with a phosphorus concentration of 0.2M. Chitosan acid solution and collagen acid solution are mixed according to the mass ratio of chitosan and collagen of 1:1, polyethylene glycol is added as a cross-linking agent, and the pH value of the solution is adjusted to 5.8 by dilute ammonia water to obtain A solution . The calcium salt solution and the phosphate salt solution are mixed according to the Ca / P molar ratio of 3:1 to obtain a B solution. Solution A and solution B were mixed according to a volume ratio of 10:1 t...

Embodiment 2

[0034] Chitosan was dissolved in dilute acetic acid to form a chitosan acid solution with a concentration of 2.5 g / L. Dissolve collagen in dilute acetic acid to form a collagen acid solution with a concentration of 2.5 g / L. CaCl 2 Dissolve in distilled water to form a calcium salt solution with a calcium concentration of 0.2M. Na 2 HPO 4 Dissolve in distilled water and stir to dissolve to form a phosphate solution with a phosphorus concentration of 0.2M. Chitosan acid solution and collagen acid solution were mixed according to the designed mass ratio of 1:1, the pH value of the solution was adjusted to 5.2 by dilute ammonia water, and glycerol was added as a cross-linking agent to obtain A solution. The calcium salt solution and the phosphate salt solution are mixed according to the molar ratio Ca:P=3:1 to obtain the B solution. Solution A and solution B were mixed according to 10:1 to obtain solution B. Mix solution B and chitosan acid solution at a ratio of 10:1 to obt...

Embodiment 3

[0036] Chitosan was dissolved in dilute nitric acid to form a chitosan acid solution with a concentration of 0.2 g / L. Dissolve collagen in dilute nitric acid to form a collagen acid solution with a concentration of 0.1 g / L. CaCl 2 ·6H 2 O was dissolved in distilled water to form a calcium salt solution with a calcium concentration of 1M. Dissolve phosphoric acid in distilled water and stir to dissolve to form a phosphate solution with a phosphorus concentration of 1M. Chitosan acid solution and collagen acid solution were mixed according to the designed mass ratio of 1:1, the pH value of the solution was adjusted to 4.8 by dilute ammonia water, and diisocyanate was added as a cross-linking agent to obtain A solution. The calcium salt solution and the phosphate salt solution are mixed according to the molar ratio Ca:P=3:1 to obtain the B solution. Solution A and solution B were mixed according to 10:1 to obtain solution B. Mix solution B and chitosan acid solution at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com