Alumina supporter for silver catalyst and silver catalyst

A technology of alumina carrier and silver catalyst, applied in catalyst carrier, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of long gas catalyst path, high energy consumption for device operation, bed To solve problems such as layer pressure drop, achieve good mass transfer and heat transfer effect, optimize flow state, and reduce mass transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

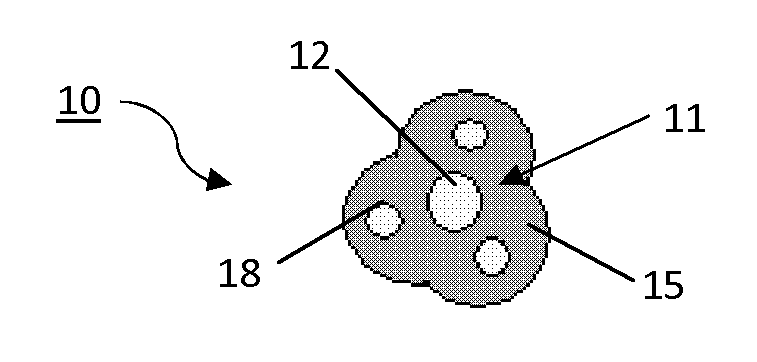

[0050] 60 ~ 400 mesh α-trihydrate Al 2 o 3 2280g and greater than 180 mesh false monohydrate Al 2 o 3 680g is put into the mixer, after mixing evenly, transfer to the kneader, add 550 milliliters of dilute nitric acid, knead into a paste that can be extruded, and then put it into the molding machine. The mold is replaced with a three-hole carrier 10 mold with three leaflets on the outer periphery, extruded into a three-hole column with an outer diameter of 8.0mm, a length of 7.0mm, and an inner diameter of 2.0mm, and dried at 90-110°C for 1 For more than an hour, the free water content is reduced to below 10%. Then put the green body into the electric furnace, raise it from room temperature to 1250 ℃ ~ 1350 ℃ after about 25 hours, and keep the temperature for 1.5 hours to obtain white α-Al 2 o 3 Carrier samples. See Table 3 for the data.

Embodiment 2

[0052] Same as Example 1, the difference is that the mold is replaced with a four-hole carrier 20 mold with four leaflets on the outer periphery, and extruded into a single-hole column with an outer diameter of 8.0 mm, a length of 7.0 mm, and an inner diameter of 1.6 mm. Carrier data are shown in Table 3.

Embodiment 3

[0054] Same as Example 1, the difference is that the mold is replaced with a five-hole carrier 30 mold with five leaflets on the outer periphery, and extruded into a five-hole column with an outer diameter of 8.0 mm, a length of 7.0 mm, and an inner diameter of 1.2 mm. Carrier data are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com