Ag catalyst for producing epoxyethane, its preparation method and uses

A technology of silver catalyst and ethylene oxide, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The present invention will be further described below in conjunction with examples, but the scope of the present invention is not limited to these examples.

[0046] Carrier 1 and 2:

[0047] 30~500 mesh trihydrate α-Al 2 o 3 312g, 30-200 mesh fake Al monohydrate 2 o 3 104g, petroleum coke 81g, NH 4 F 7g, Mg(NO 3 ) 2 8.5g and BaSO 4 0g and 1.2g were respectively put into a mixer and mixed evenly, transferred to a kneader, added 0.18 liters of dilute nitric acid (nitric acid: water=1:3, weight ratio), and kneaded into a paste that could be extruded. Extruded into a ring with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 2.0mm, and dried at 80-120°C for more than 2 hours to reduce the free water content to below 10%.

[0048] Put the above two rings into a bell kiln, raise the temperature from room temperature to 1350°C to 1550°C after about 30 hours, and keep the temperature for 2 hours to obtain white α-Al 2 o 3 Carrier Sample 1 and C...

Embodiment 1-9

[0060] The same procedure as Comparative Examples 1-3 was repeated except that the impregnation solution additionally contained cerium sulfate in the amount shown in Table 2 below.

[0061] Example number

carrier number

The amount of cerium sulfate added (g)

Example 1

1

0.09

Example 2

1

0.17

Example 3

1

0.35

Example 4

2

0.09

Example 5

2

0.17

Example 6

2

0.35

Example 7

3

0.09

Example 8

3

0.17

Example 9

3

0.35

[0062] The silver and promoter content of the prepared catalyst were analyzed, and the results are listed in Table 3 below, wherein the content is calculated as metal.

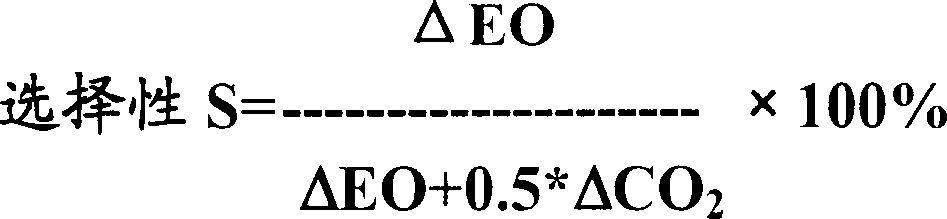

[0063] The activity and selectivity of the catalyst samples were measured under the aforementioned process conditions using a microreactor evaluation device, and the test results are listed in Table 3 below.

[0...

Embodiment 10-12

[0069] The same procedure as Comparative Example 4 was repeated except that the impregnating solution additionally contained cerium acetate or cerium oxalate in the amount shown in Table 4 below.

[0070] Example number

Types of cerium additives

Amount added (g)

Example 10

Cerium acetate

0.19

Example 11

Cerium acetate

0.38

Example 12

0.15

[0071] The silver and additive content of the prepared catalyst were analyzed, and the results are listed in Table 5 below, wherein the content is calculated as metal.

[0072] The activity and selectivity of the catalyst samples were measured under the aforementioned process conditions using a microreactor evaluation device, and the test results are listed in Table 5 below.

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com