Preparation method of silver catalyst carrier, carrier prepared by preparation method, silver catalyst prepared by carrier and application thereof

A technology of silver catalyst and alumina carrier, which is applied in the direction of catalyst carrier, catalyst activation/preparation, molecular sieve catalyst, etc. It can solve the problems of catalyst selectivity and activity decline, easy aggregation of silver particles, and low stability of silver catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1 (comparison)

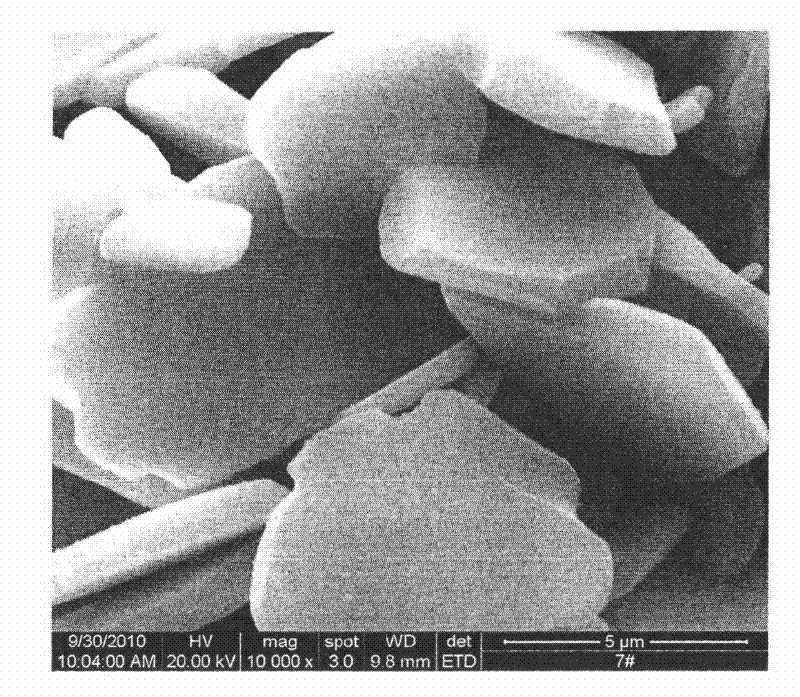

[0082] 200-500 mesh trihydrate α-Al 2 o 3 403g, 200-400 mesh fake Al monohydrate 2 o 3 81g, NH 4 F 7g and BaSO 4 1.0 g was put into a mixer and mixed evenly, then transferred to a kneader, added 90 milliliters of dilute nitric acid (nitric acid: water=1:3, weight ratio), and kneaded into a paste that could be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry at 80-120°C for 10 hours to reduce the free water content below 10% by weight to obtain a green body. Then put the green body into the electric furnace, raise it from room temperature to 1400 ° C over 30 hours, and then keep the temperature for 2 hours to obtain white α-Al 2 o 3 Carrier sample, named Z-1, the scanning electron microscope photo of the carrier is shown in figure 1 . Z-1 is a comparative example of the carrier sample obtained in Example 2-4.

Embodiment 2

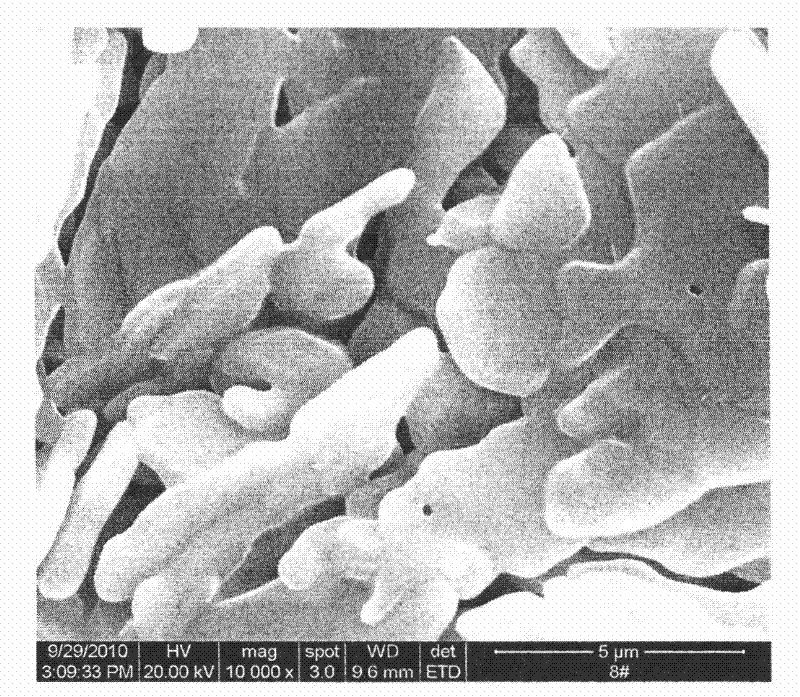

[0084] 200-500 mesh trihydrate α-Al 2 o 3 379g, 200-400 mesh fake Al monohydrate 2 o 3 76g, TS-1 molecular sieve 30g, NH 4 F 7g and BaSO 4 1.0 g was put into a mixer and mixed evenly, then transferred to a kneader, added 84 ml of dilute nitric acid (nitric acid: water=1:3, weight ratio), and kneaded into a paste that could be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry at 80-120°C for 10 hours to reduce the free water content below 10% by weight to obtain a green body. Then put the green body into the electric furnace, raise it from room temperature to 1400 ° C over 30 hours, and then keep the temperature for 2 hours to obtain white α-Al 2 o 3 Carrier sample, named Z-2, the scanning electron microscope photo of the carrier is shown in figure 2 .

[0085] by comparison figure 1 with figure 2 It can be seen that the surface of the Z-2 carrier is smoother than that of the Z-1 car...

Embodiment 3

[0087] 200-500 mesh trihydrate α-Al 2 o 3 367g, 200-400 mesh fake Al monohydrate 2 o 3 74g, TS-1 molecular sieve 44g, NH 4 F 7g and BaSO 4 1.0 g was put into a blender and mixed evenly, then transferred to a kneader, added 83 ml of dilute nitric acid (nitric acid: water=1:3, weight ratio), and kneaded into a paste that could be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry at 80-120°C for 10 hours to reduce the free water content below 10% by weight to obtain a green body. Then put the green body into the electric furnace, raise it from room temperature to 1400 ° C over 30 hours, and then keep the temperature for 2 hours to obtain white α-Al 2 o 3 Carrier sample, named Z-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com