Carrier of silver catalyst for producing ethylene oxide, preparation method thereof, silver catalyst prepared by using same and application thereof in producing ethylene oxide

A technology of silver catalyst and ethylene oxide, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve unmentioned problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

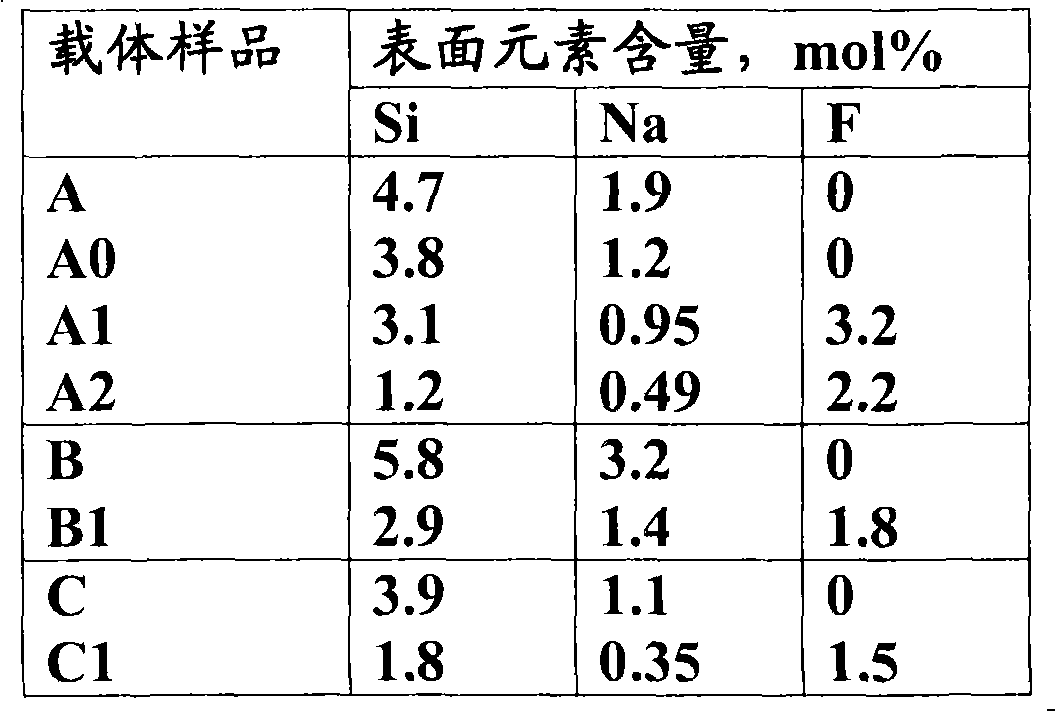

Embodiment 1-1 and 1-2

[0082] Using the same impregnating solution in the above comparative example 1, get each 30g of the carrier A1 and A2 of the present invention, respectively place them in a vacuumable container, vacuumize to more than 10mmHg, put into about 60g of the above silver-containing impregnating solution respectively, and immerse the carrier , kept for 30 minutes, leached to remove excess solution, then heated in 300° C. air flow for 5 minutes, and cooled to prepare silver catalysts 1-1 and 1-2 of the present invention.

[0083] Under the reaction conditions that the concentration of ethylene oxide at the outlet of the reactor as described above is 2.5% (molar concentration), catalysts 1-1, 1-2 of the present invention and comparative catalyst 1 are compared and evaluated simultaneously, and the obtained results are shown in the following table 2 .

[0084] Table 2

[0085] sample

[0086] sample

[0087] The above Table 2 shows that the catalysts 1-1 and 1-2 of t...

Embodiment 2

[0092] Get 30g of the carrier B1 of the present invention, place it in a vacuumable container, vacuumize it to more than 10mmHg, put about 60g of the impregnating solution in Comparative Example 2, immerse the carrier, keep it for 30 minutes, remove excess solution by leaching, and then The silver catalyst 2 of the present invention was prepared by heating in an air stream at 300° C. for 5 minutes and cooling.

[0093] The above comparison silver catalyst 2 and the silver catalyst 2 of the present invention were compared and evaluated under the reaction conditions that the concentration of ethylene oxide at the outlet of the reactor was 2.5% (molar concentration) as described above, and the results are shown in Table 3 below.

[0094] table 3

[0095] sample

[0096] sample

Embodiment 3

[0101] Using the same impregnating solution in the above comparative example 3, get the carrier C1 30g of the present invention, place it in a container that can be vacuumed, and evacuate it to more than 10mmHg, put into about 60g of the silver-containing solution described in the comparative example 3, and immerse the carrier , kept for 30 minutes, leached to remove excess solution, then heated in air flow at 300° C. for 5 minutes, and cooled to prepare the silver catalyst 3 of the present invention.

[0102] The above comparison silver catalyst 3 and the silver catalyst 3 of the present invention were compared and evaluated under the reaction conditions that the concentration of ethylene oxide at the outlet of the reactor was 2.5% (molar concentration) as described above, and the results are shown in Table 4 below.

[0103] Table 4

[0104] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com