Production process and device of formaldehyde

A production device and production process technology, applied in the field of formaldehyde production process and device, can solve the problems of short life of waste heat boiler, increased power consumption, long process flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

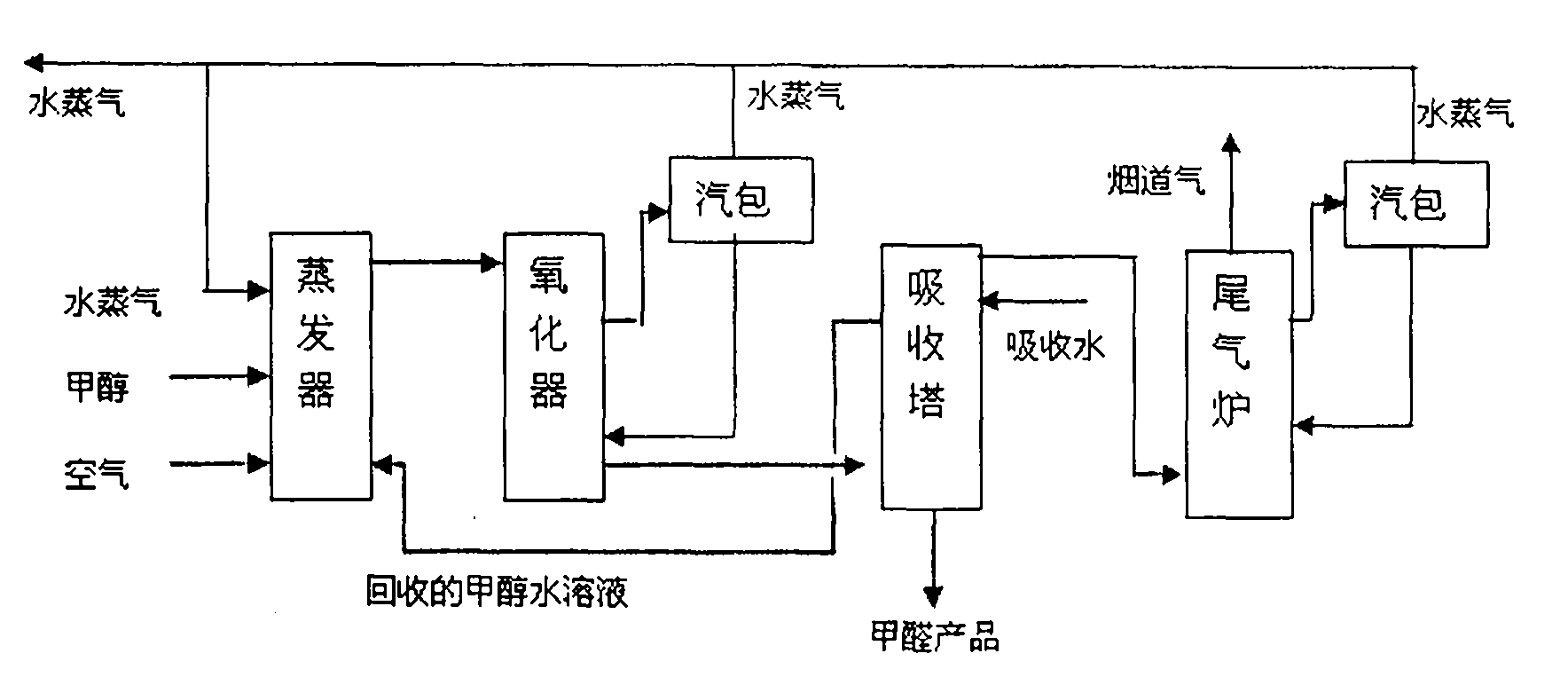

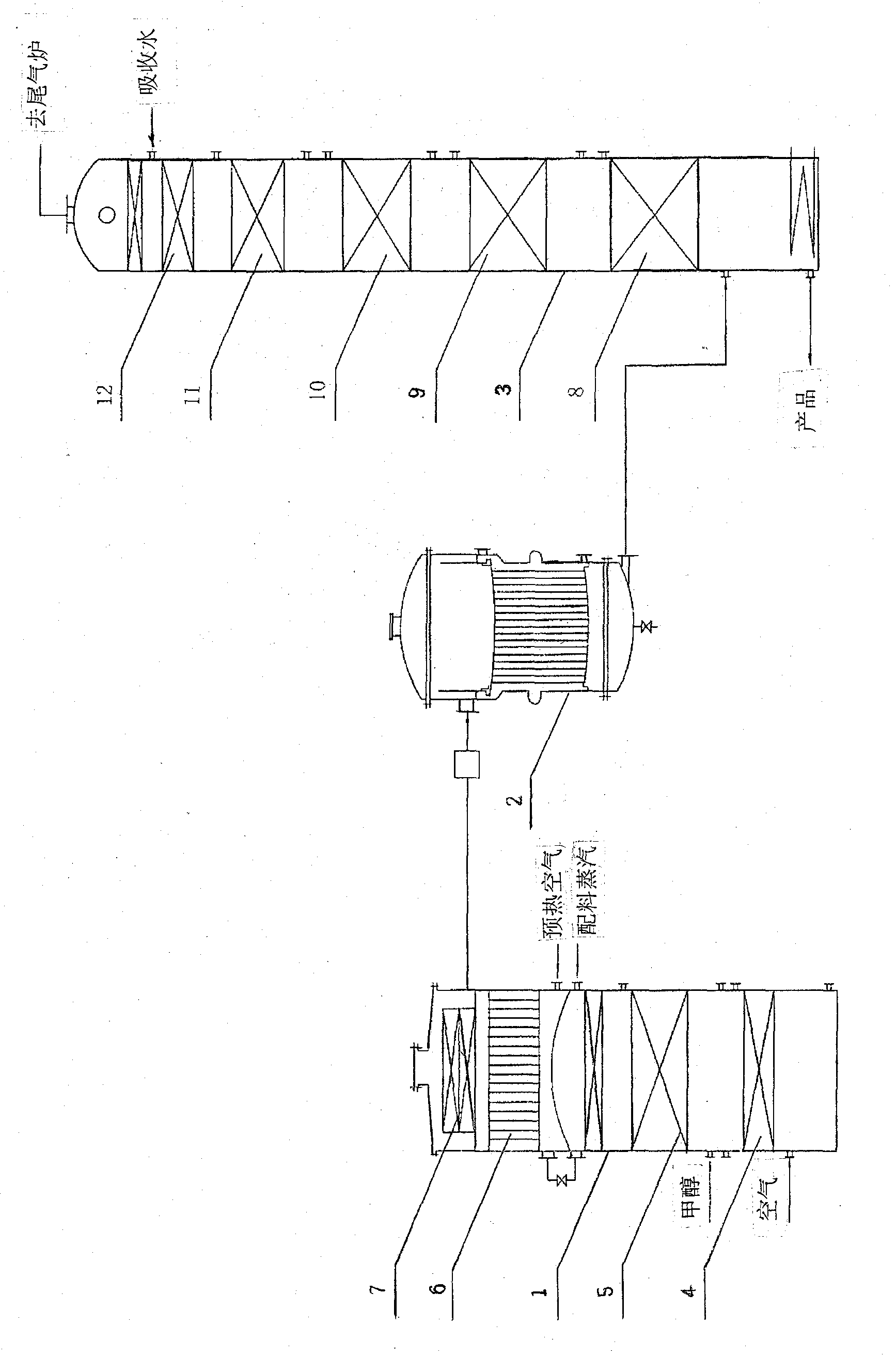

[0067] Embodiment 1, the formaldehyde production technique of the best implementation mode as shown in the figure, its technological process is as follows:

[0068] The air is filtered through the air filter, boosted by the Roots blower, and metered by the flowmeter into the bottom of the evaporator 1, and then reversely contacts the heated raffinate circulating fluid through the filler above, evaporates the methanol and water in the raffinate, and forms an air mixture Gas; the recovered dilute methanol and / or water containing a small amount of formaldehyde is metered into the evaporation section 5 of the evaporator through a flow meter; the methanol is fed from the methanol metering tank to the evaporator 1 evaporation section through a methanol pump, filtered by a filter, and metered by a flow meter 5. Mix with recovered methanol aqueous solution at the bottom of the evaporation section of the evaporator to form methanol mixed liquid; the raffinate circulating liquid is that ...

Embodiment 2

[0085] Same as the method in Example 1, the formed methanol-air-water vapor ternary gas is demisted and flame-retardant, mixed with a small amount of water vapor, the minimum amount of water vapor is zero, superheated to 110°C, and filtered throughout the process. The amount of methanol evaporation is controlled by adjusting the gas phase temperature and the equilibrium concentration of methanol in the evaporation section 5, so that the molar ratio of oxygen to methanol reaches 0.35. The ternary gas is catalyzed by a silver catalyst, and the dehydrogenation and oxidation reaction of methanol is carried out at a high temperature of 620 ° C to generate formaldehyde gas;

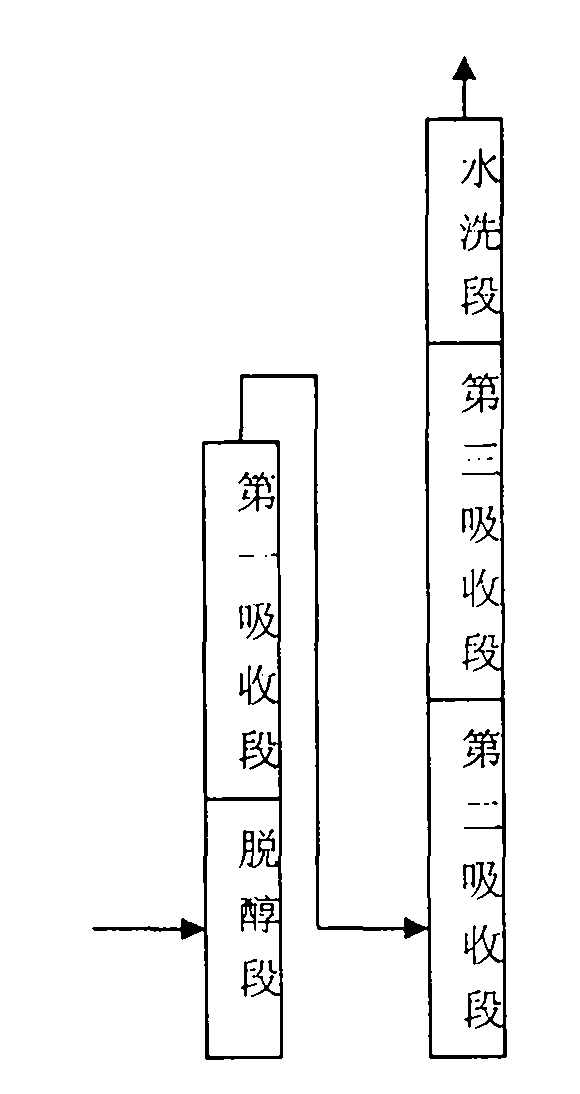

[0086] The higher-temperature generated gas leaving the waste heat boiler enters the absorption tower 3, and passes through the dealcoholization section 8, the first absorption section 9, the second absorption section 10, the third absorption section 11, and the water washing section 12 from bottom to top. Afte...

Embodiment 3

[0094] Same as the method in Example 1, the formed methanol-air-water vapor ternary gas is demisted and mixed with a small amount of water vapor, the minimum water vapor content is zero, superheated to 120°C, flame retardant, and filtered throughout the process. The amount of methanol evaporation is controlled by adjusting the vapor phase temperature and the equilibrium concentration of methanol in evaporation section 5, so that the molar ratio of oxygen to methanol reaches 0.37. The ternary gas is catalyzed by a silver catalyst, and the dehydrogenation and oxidation reaction of methanol is carried out at a high temperature of 630 ° C to generate formaldehyde gas;

[0095] The higher-temperature generated gas leaving the waste heat boiler enters the absorption tower 3, and passes through the dealcoholization section 8, the first absorption section 9, the second absorption section 10, the third absorption section 11, and the water washing section 12 from bottom to top. After le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com