Alumina carrier, preparation method, silver catalyst prepared by alumina carrier, and application thereof

A technology of alumina carrier and silver catalyst, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

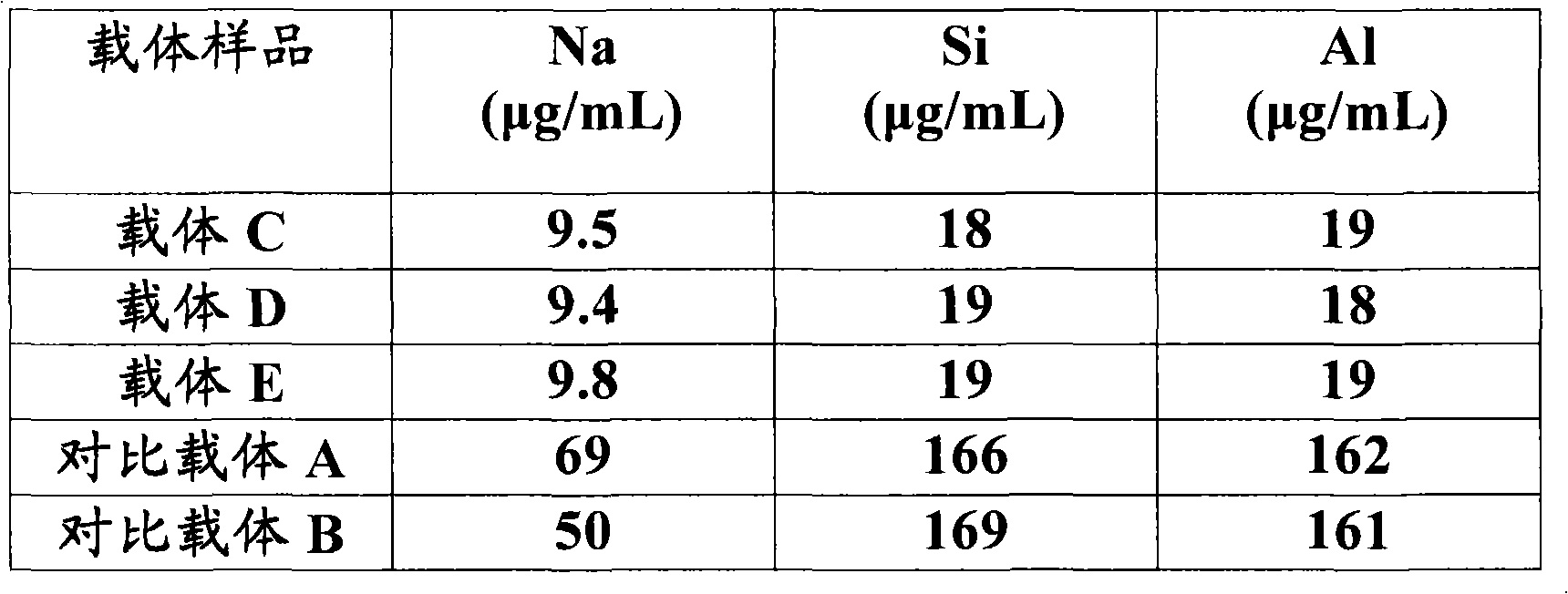

[0091] Example Vectors C, D and E

[0092] Take 120 g of the carrier A obtained above and place it in an acid-resistant plastic cup, inject 240 g of an oxalic acid aqueous solution with a pH value of 0.75 at 25°C into it, soak it at room temperature for 40 minutes, then remove the solution by leaching, soak and wash the sample with 150 g of distilled water for 20 minutes, and drain Water was removed by filtration, washed four times until the pH value of the leachate was greater than 5, and then dried in a flowing air stream at 260° C. for 10 minutes to obtain carrier C. The specific surface area of carrier C is 0.98m 2 / g, water absorption rate 50.8%, total pore volume 0.62ml / g, lateral pressure strength 72 Newton / grain, alkaline earth metal magnesium content 0.48wt%.

[0093] The same as the preparation process of carrier C, the difference is: after washing, it is dried in a flowing air stream at 400° C. for 5 minutes to prepare carrier D. The specific surface area of ...

Embodiment 1、2 and 3

[0128] Take each 10g of carriers C, D and E, place them in a vacuumable container respectively, evacuate to less than 10mmHg, and put them into the silver-containing impregnated solution described in Comparative Examples 1 and 2 of the above "Catalyst Preparation" section respectively. Liquid X 20g, immerse the carrier, keep it for 30 minutes, then leach to remove the excess solution, then heat it in the air stream of 250°C for 5 minutes, cool down, and prepare the inventive catalysts 1, 2 and 3 respectively, and measure their silver content 18.3%wt, 18.1%wt and 18.3wt%, respectively.

[0129] See Table 5 for the additive contents of comparative catalysts 1 and 2 and inventive catalysts 1, 2 and 3.

[0130] table 5

[0131]

[0132]

[0133] Under the conditions given in the above "Measurement of Catalyst Performance" section, Invention Catalysts 1, 2 and 3 and Comparative Catalysts 1 and 2 were compared and evaluated respectively, wherein the space velocity was 5000h ...

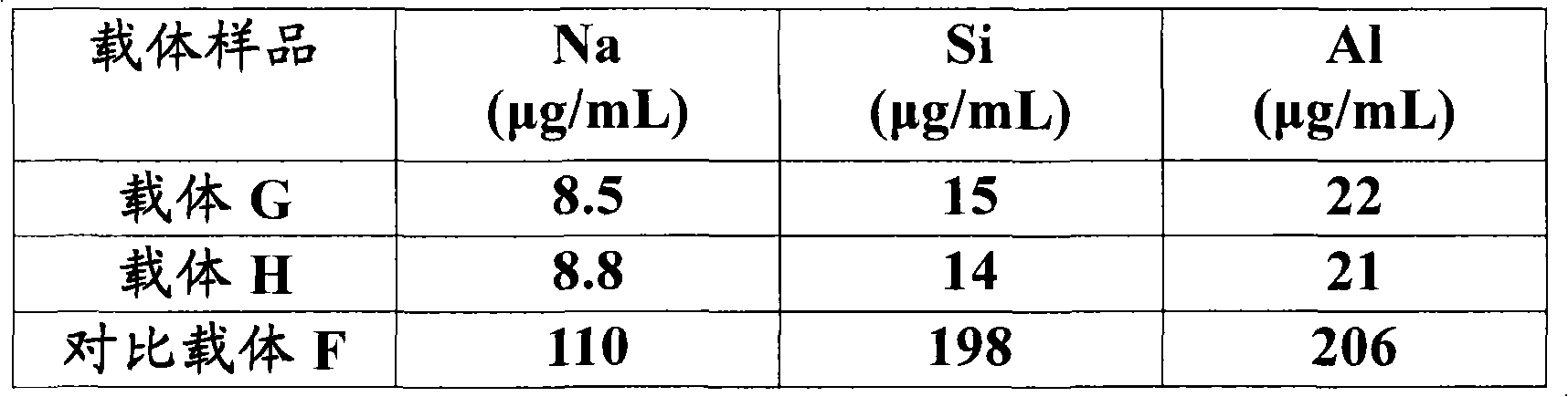

Embodiment 4、5 and 6

[0141] Get each 20g of carrier G, H and I, place in the container that can be vacuumized separately, evacuate to be lower than 10mmHg, add respectively the silver-containing impregnating liquid Y 40g described in the comparative example 3 of the above "catalyst preparation" part , immerse the carrier and keep it for 30 minutes, then leach to remove the excess solution, then heat it in the air flow at 250°C for 5 minutes, and cool it down to prepare the inventive catalysts 4, 5 and 6, whose silver content is respectively 19.1wt after measuring %, 19.0 wt% and 19.2%.

[0142] See Table 7 for the additive contents of comparative catalysts 3 and 4 and inventive catalysts 4, 5 and 6.

[0143] Table 7

[0144]

[0145]Under the conditions given in the "Measurement of Catalyst Performance" section above, Invention Catalysts 4, 5 and 6 and Comparative Catalysts 3 and 4 were simultaneously compared and evaluated respectively, wherein the space velocity was 5000h -1 , the concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com