Catalyst carrier and preparation method as well as catalyst prepared by carrier and application of catalyst

A catalyst carrier and carrier technology, applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited improvement of carrier performance and catalyst activity and selectivity, and achieve performance improvement and selectivity improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

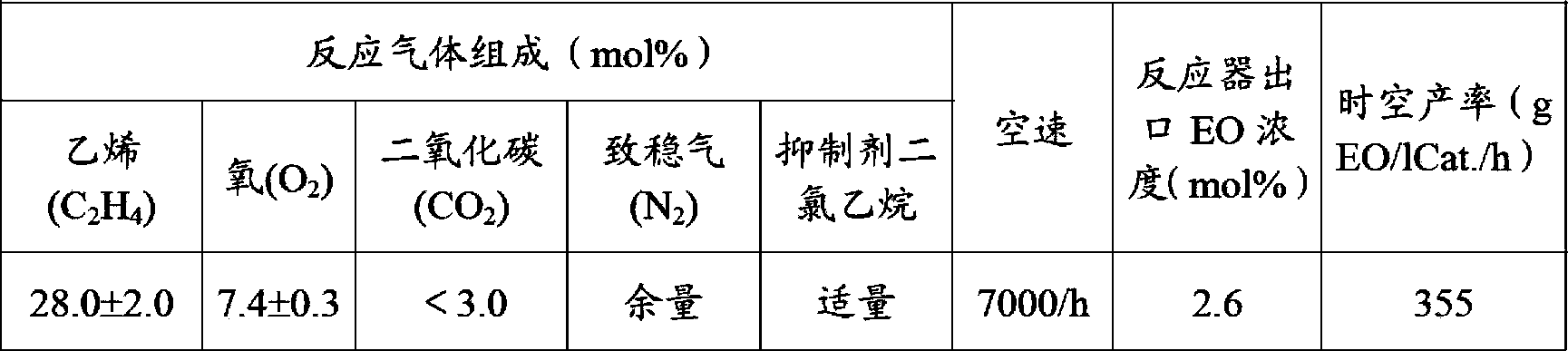

Examples

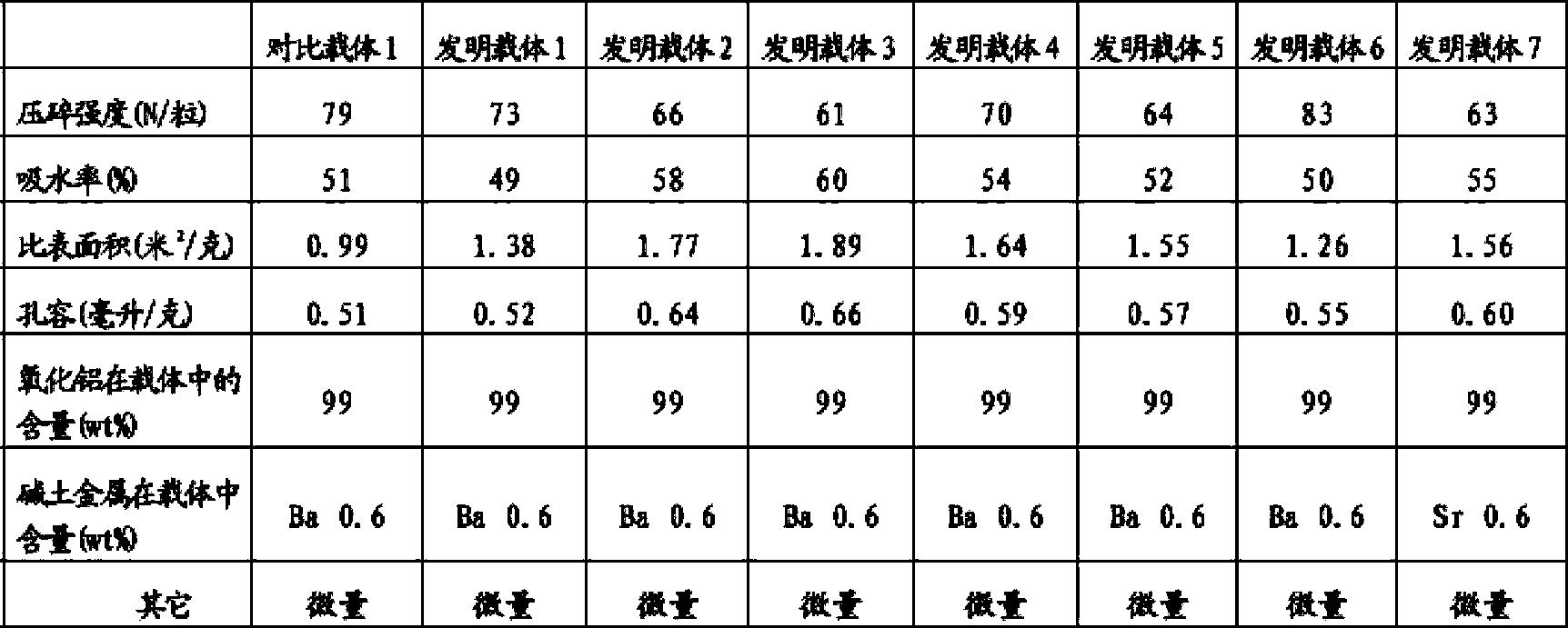

Embodiment 1

[0077] α-A1 2 o 3 Powder 400g, fake monohydrate A1 through 200 mesh sieve 2 o 3 100g, ammonium fluoride 10g, BaSO 4 3g was put into a mixer and mixed evenly, then transferred to a kneader, and 100 milliliters of 20% by weight nitric acid aqueous solution was added, and kneaded into a paste that could be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry at 80-120°C for 2 hours to reduce the free water content to below 10% by weight to obtain a green body. Then put the green body into an electric furnace, raise it from room temperature to 1400°C, and keep the temperature at this high temperature for 2 hours to obtain white α-A1 2 o 3 A carrier sample, referred to as Invention Vector 1.

Embodiment 2

[0079] The preparation of the inventive carrier 2 is similar to the preparation of the inventive carrier 1, only the "α-A1 2 o 3 "Powder 400g" is changed to "γ-A1 2 o 3 Powder 400g".

Embodiment 3

[0081] The preparation of the inventive carrier 3 is similar to the preparation of the inventive carrier 1, only the "α-A1 2 o 3 "Powder 400g" is changed to "ρ-A1 2 o 3 Powder 400g".

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com