Silicon dioxide supported nano-silver catalyst, preparation and use thereof

A silicon dioxide and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, preparation of amino compounds, etc., can solve the problems of high cost, poor selectivity, inconvenient transportation, etc. The effect of reducing catalyst cost, mild reaction conditions and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

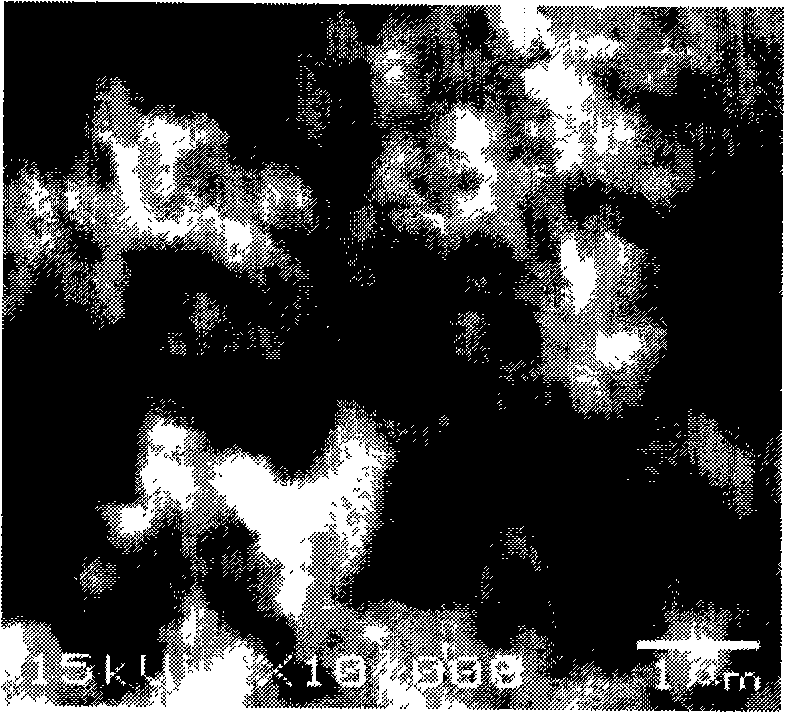

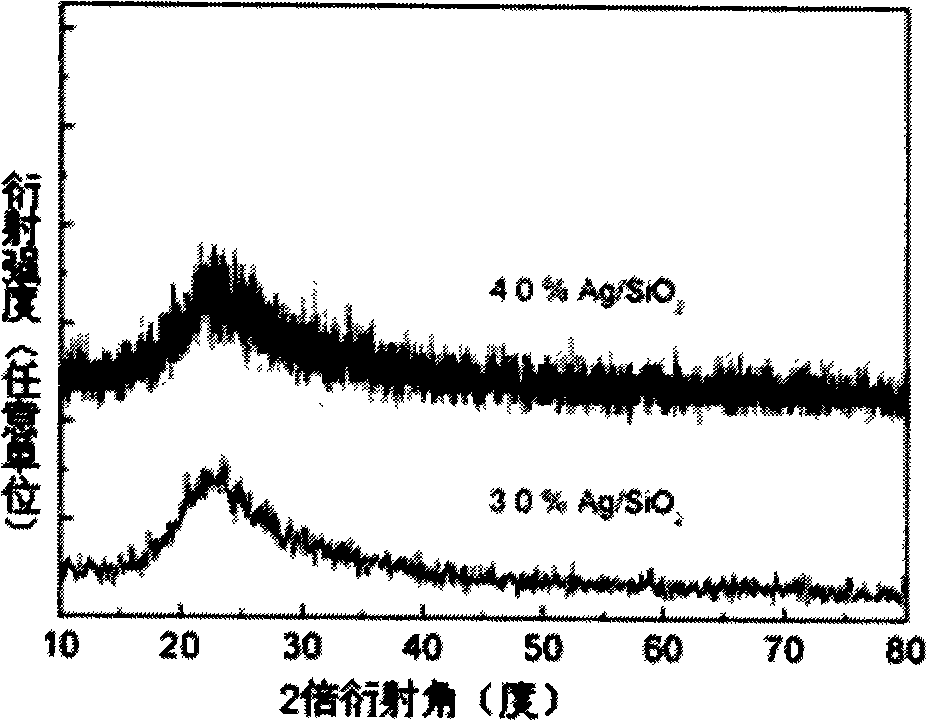

Image

Examples

Embodiment 1

[0031] In the stainless steel reactor of 100ml, add 0.5 nitropyrene, 30ml ethanol and 0.10g catalyst 1# (Ag load capacity 1.0%), seal autoclave, fill H 2 Inflate to a pressure of 2.0MPa, then vent. Repeat the operation three times to remove the air in the kettle. Finally H 2 Charge to 2.0MPa, heat to 140°C, and react for 3.0 hours. During the reaction process, mechanical stirring was carried out at a speed of 900 revolutions per minute (900 r.p.m.). After the reaction was over, the reactor was naturally cooled to room temperature, and N 2 The gas is purged twice to remove the H in the kettle 2 . The catalyst is recovered from the reaction solution by centrifugation at a speed of 12000 r.p.m. The catalyst was washed three times with ethanol (3*5ml), and dried under vacuum at 60°C for recycling. The organic clear liquid was diluted with methanol and then analyzed and identified by GCMS-QP2010 (SHIMADZU) gas spectrometer. The results showed that the conversion rate of nitr...

Embodiment 2

[0033] In the stainless steel reactor of 100ml, add 0.5g nitropyrene, 30ml ethanol and 0.10g catalyst (Ag loading capacity 2.0%), seal autoclave, fill H 2 Inflate to a pressure of 2.0MPa, then vent. Repeat the operation three times to remove the air in the kettle. Finally H 2 Charge to 3.0MPa, heat to 140°C, and react for 3.0 hours. During the reaction process, mechanical stirring was carried out at a speed of 900 revolutions per minute (900 r.p.m.). After the reaction was over, the reactor was naturally cooled to room temperature, and N 2 The gas is purged twice to remove the H in the kettle 2 . The catalyst is recovered from the reaction solution by centrifugation at a speed of 12000 r.p.m. The catalyst was washed three times with ethanol (3*5ml), and dried under vacuum at 60°C for recycling. The organic clear liquid was diluted with methanol and then analyzed and identified by GCMS-QP2010 (SHIMADZU) gas spectrometer. The results showed that the conversion rate of nit...

Embodiment 3

[0035] In the stainless steel reactor of 100ml, add 0.5g nitropyrene, 30ml ethanol and 0.10g catalyst (Ag loading capacity 3.0%), seal autoclave, fill H 2 Inflate to a pressure of 2.0MPa, then vent. Repeat the operation three times to remove the air in the kettle. Finally H 2 Charge to 2.0MPa, heat to 140°C, and react for 3.0 hours. During the reaction process, mechanical stirring was carried out at a speed of 900 revolutions per minute (900 r.p.m.). After the reaction was over, the reactor was naturally cooled to room temperature, and N 2 The gas is purged twice to remove the H in the kettle 2 . The catalyst is recovered from the reaction solution by centrifugation at a speed of 12000 r.p.m. The catalyst was washed three times with ethanol (3*5ml), and dried under vacuum at 60°C for recycling. The organic clear liquid was diluted with methanol and then analyzed and identified by GCMS-QP2010 (SHIMADZU) gas spectrometer. The results showed that the conversion rate of nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com