Method, sintering aid and materials for preparation of low-temperature cofired medium ceramic and application

A dielectric ceramic and low-temperature co-firing technology, applied in the field of dielectric ceramic materials, can solve the problems of low dielectric properties and low mechanical strength of substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

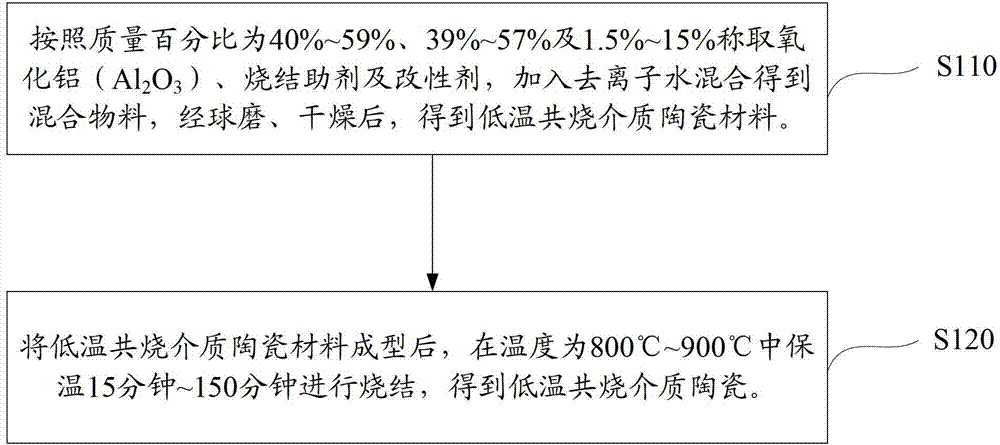

[0026] Such as figure 1 Shown, the preparation method of the low-temperature co-fired dielectric ceramic of one embodiment, comprises the following steps:

[0027] Step S110: Weighing alumina (Al 2 o 3 ), sintering aids and modifiers, adding deionized water and mixing to obtain a mixed material, after ball milling and drying, a low temperature co-fired dielectric ceramic material is obtained. Among them, the modifier is titanium dioxide (TiO 2 ), manganese dioxide (MnO 2 ), cobalt tetroxide (Co 3 o 4 ), Yttrium trioxide (Y 2 o 3 ), zirconium dioxide (ZrO 2 ) and bismuth trioxide (Bi 2 o 3 ) at least one of the

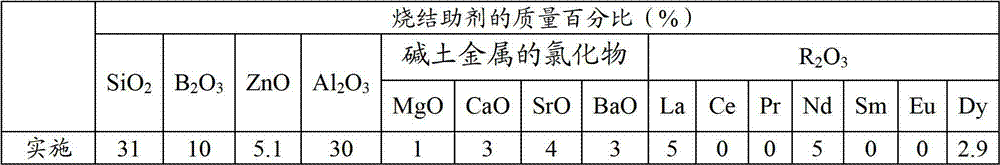

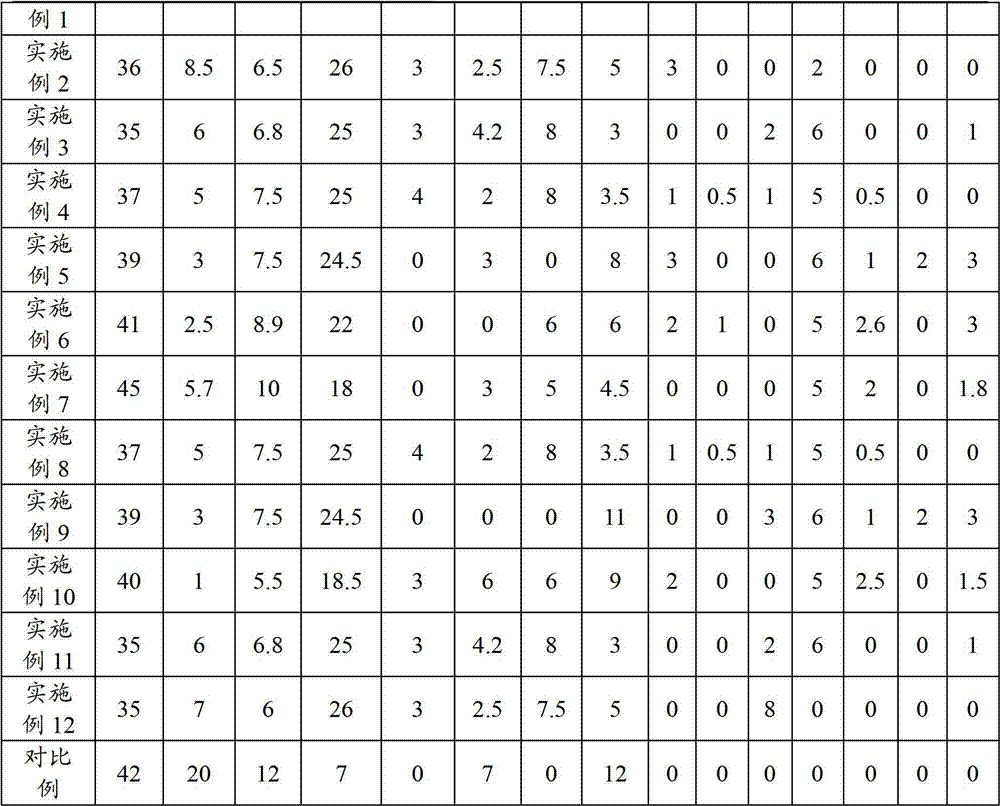

[0028] Among them, by mass percentage, the sintering aid includes 31%~45% of silicon dioxide (SiO 2 ), 1%~10% boron oxide (B 2 o 3 ), 5.1%~10% zinc oxide (ZnO), 18%~30% aluminum oxide (Al 2 o 3 ), 11%~24% of alkaline earth metal oxides and 5%~15% of the general formula R 2 o 3 of oxides. Wherein, R is at least one of lanthanum (La), cerium (Ce), pras...

Embodiment 1

[0038] The composition of the low temperature co-fired dielectric ceramic material in this embodiment is shown in Table 1 and Table 2.

[0039] The preparation of low temperature co-fired dielectric ceramics in this embodiment is as follows:

[0040] (1) Preparation of sintering aid: aluminum chloride (AlCl 3 ), magnesium chloride (MgCl 2 ), calcium chloride (CaCl 2 ), strontium chloride (SrCl 2 ), barium chloride (BaCl 2 ), lanthanum chloride (LaCl 3 ), neodymium chloride (NdCl 3 ), dysprosium chloride (DyCl 3 ) as a raw material, each raw material is prepared into an aqueous solution, and mixed according to the mass percentage of each component in the sintering aid, and then ammonium bicarbonate (NH 4 HCO 3 ), using the chemical co-precipitation method to generate the precursor precipitates of each component, after filtration and washing, the silica (SiO 2 ), zinc oxide (ZnO), boric acid (H 3 BO 3 ) as the raw material, according to the silicon dioxide (SiO 2 ), ...

Embodiment 2

[0045] The composition of the low temperature co-fired dielectric ceramic material in this embodiment is shown in Table 1 and Table 2.

[0046] The preparation of low temperature co-fired dielectric ceramics in this embodiment is as follows:

[0047] (1) Preparation of sintering aid: aluminum chloride (AlCl 3 ), magnesium chloride (MgCl 2 ), calcium chloride (CaCl 2 ), strontium chloride (SrCl 2 ), barium chloride (BaCl 2 ), lanthanum chloride (LaCl 3 ), neodymium chloride (NdCl 3 ) as a raw material, each raw material is prepared into an aqueous solution respectively, and is mixed according to the mass percentage of each component in the sintering aid, and then potassium carbonate (K 2 CO 3 ), using the chemical co-precipitation method to generate the precursor precipitates of each component, after filtration and washing, the silica (SiO 2 ), zinc oxide (ZnO), boric acid (H 3 BO 3 ) as the raw material, according to the silicon dioxide (SiO 2 ), zinc oxide (ZnO), b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com