Nanometer rare earth permanent magnetic material with high-temperature stability and preparation method thereof

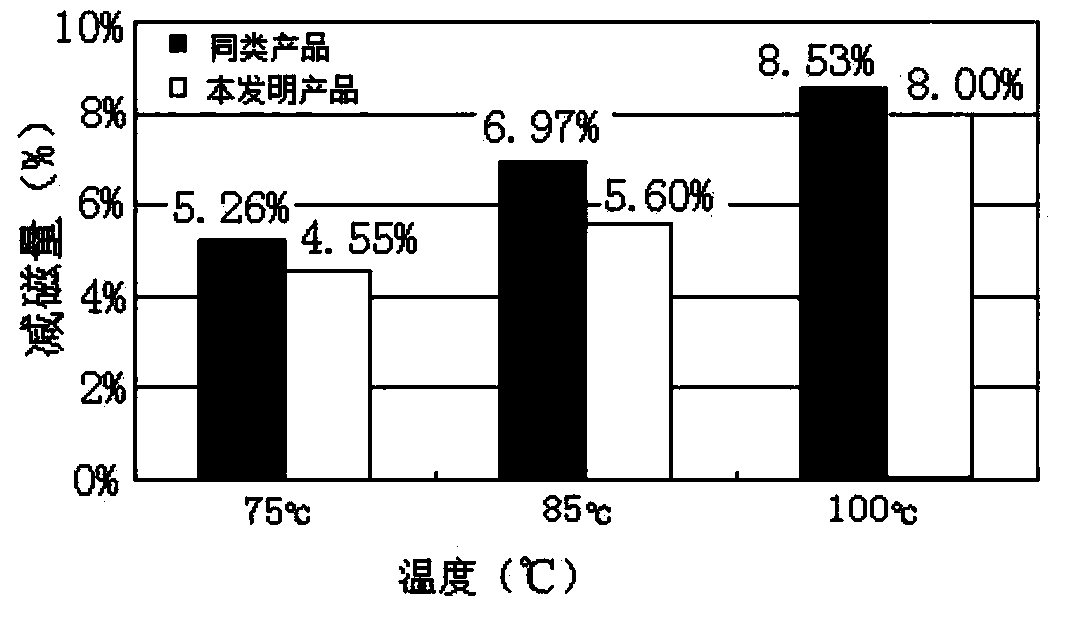

A permanent magnet material and nano-rare earth technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of limiting the scope of use of magnets, unfavorable promotion and application, and low operating temperature, so as to reduce the performance of magnets and inhibit nucleation Grow up, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the following formula, the purity of Nd is 99.9%, the atomic percentage is 29%, the Fe-B alloy (in which B content is 19%), the atomic percentage of B is 2.8%, the atomic percentage of Nb is 4.2%, and the rest is Fe content . Under the protection of the inert gas argon, put it into a vacuum smelting furnace for smelting to obtain 50 kilograms of alloy ingots with uniform composition, and then the obtained alloy ingots are subjected to rapid quenching (see image 3 ), the wheel speed is about 20-39m / s, and after obtaining the thin metal strip, it is crushed through a 40-mesh sieve, crystallized at a temperature of 500°C-700°C for 10 minutes, and the prepared sample is used with a vibrating sample magnetometer (VSM) Measure its magnetic performance, performance as shown in table 1:

[0019] Table 1

[0020]

[0021] It can be seen from the data in Table 1 that rare earth permanent magnet materials can obtain products with high coercive force and a maximu...

Embodiment 2

[0023] According to the following formula, the purity of Nd is 99.9%, the atomic percentage is 24%, the Fe-B alloy (in which B content is 19%), the atomic percentage of B is 3.5%, the atomic percentage of Nb is 4.8, and the rest is Fe content. Repeat the preparation process of sample 1, and measure the magnetic properties of the prepared sample with a vibrating sample magnetometer (VSM), and the performance is as shown in Table 2:

[0024] Table 2

[0025]

[0026] It can be seen from the data in Table 2 that rare earth permanent magnet materials can obtain products with high coercive force and a maximum working temperature of 150-180°C when the magnetic energy product BH(max) maintains good performance.

Embodiment 3

[0028] According to the following formula, the purity of Nd is 99.9%, the atomic percentage is 22.6%, the Fe-B alloy (in which B content is 19%), the atomic percentage of B is 3.8%, the atomic percentage of Nb is 5.2%, and the rest is Fe content . Repeat the preparation process of sample 1, and measure the magnetic properties of the prepared sample with a vibrating sample magnetometer (VSM), and the performance is as shown in Table 3:

[0029] table 3

[0030]

[0031] It can be seen from the data in Table 3 that rare earth permanent magnet materials can obtain products with high coercive force and a maximum working temperature of 150-180°C when the magnetic energy product BH(max) maintains good performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com