NdFeB magnet formed by sintering NdFeB recycling waste and preparation method of NdFeB magnet

A technology for recycling waste and NdFeB, applied in the direction of magnetic objects, inorganic materials, magnetic materials, etc., can solve the problem of low utilization rate of NdFeB waste, difficult to meet high requirements, and poor performance of NdFeB magnets and other problems, to achieve the effect of improving the milling effect, good particle size concentration, and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

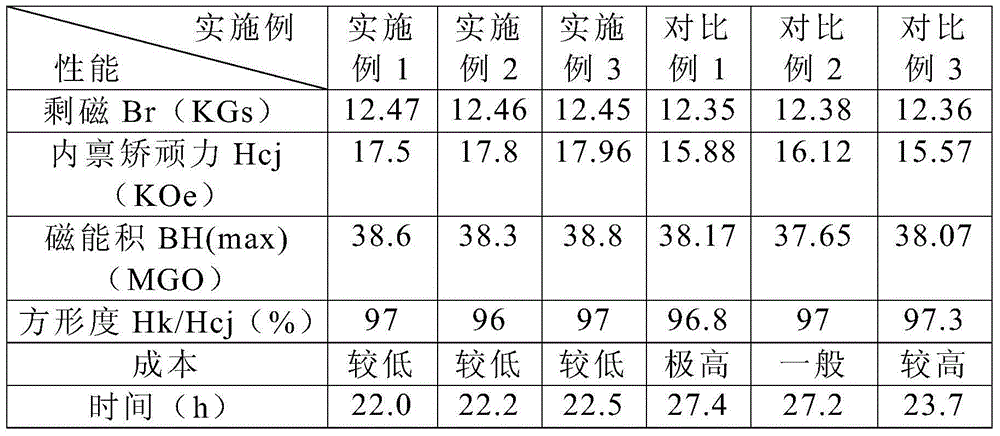

Examples

Embodiment 1

[0027] A neodymium iron boron magnet sintered from neodymium iron boron recycling waste, said neodymium iron boron magnet is prepared by a sintering process through a mixture of neodymium iron boron recycling waste and neodymium iron boron compounding material, wherein The mass percentages of the NdFeB recycling waste and the NdFeB preparation are 20% and 80% respectively; the components and their mass percentages in the NdFeB recycling waste are: (PrNd) 26 Gd 3 Dy 0.1 Co 0.5 Al 0.8 Cu 0.1 B 0.98 Fe bal ; The components and their mass percentages in the NdFeB compound are: (PrNd) 29 Gd 4 Co 0.5 Al 0.8 Cu 0.1 B 0.98 Fe bal ;

[0028] The method for preparing the NdFeB magnet sintered from the NdFeB recycling waste in this embodiment includes the following steps:

[0029] Weigh the raw materials according to the ingredients and their mass percentages in the above-mentioned NdFeB formulations, and then smelt them in a vacuum quick-setting furnace with a vacuum of 0.5Pa at a smeltin...

Embodiment 2

[0035] A neodymium iron boron magnet sintered from neodymium iron boron recycling waste, said neodymium iron boron magnet is prepared by a sintering process through a mixture of neodymium iron boron recycling waste and neodymium iron boron compounding material, wherein The mass percentages of the NdFeB recycling waste and the NdFeB preparation are 30% and 70% respectively; the components and their mass percentages in the NdFeB recycling waste are: (PrNd) 26 Gd 3 Dy 0.1 Co 0.5 Al 0.8 Cu 0.1 B 0.98 Fe bal ; The components and their mass percentages in the NdFeB compound are: (PrNd) 29 Gd 3.5 Co 0.5 Al 0.8 Cu 0.1 B 0.98 Fe bal ;

[0036] The method for preparing the NdFeB magnet sintered from the NdFeB recycling waste in this embodiment includes the following steps:

[0037] Weigh the raw materials according to the ingredients and their mass percentages in the above-mentioned NdFeB compound, and then smelt them in a vacuum quick-setting furnace with a vacuum of 0.3Pa. The smelting ...

Embodiment 3

[0043] A neodymium iron boron magnet sintered from neodymium iron boron recycling waste, said neodymium iron boron magnet is prepared by a sintering process through a mixture of neodymium iron boron recycling waste and neodymium iron boron compounding material, wherein The mass percentages of the NdFeB recycling waste and the NdFeB preparation are 40% and 60% respectively; the components and their mass percentages in the NdFeB recycling waste are: (PrNd) 26 Gd 3 D y0.1 Co 0.5 Al 0.8 Cu 0.1 B 0.98 Fe bal ; The components and their mass percentages in the NdFeB compound are: (PrNd) 30 Gd 3 Co 0.5 Al 0.8 Cu 0.1 B 0.98 Fe bal ;

[0044] The method for preparing the NdFeB magnet sintered from the NdFeB recycling waste in this embodiment includes the following steps:

[0045] Weigh the raw materials according to the ingredients and their mass percentages in the above-mentioned NdFeB compound, and then smelt them in a vacuum quick-setting furnace with a vacuum of 0.8Pa, and the melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com