Low-cost N35 NdFeB magnet with high cerium content and sintering method thereof

A sintering method and NdFeB technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of high material cost, deterioration of magnetic properties, failure to reduce costs, etc., to ensure comprehensive magnetic properties. , the effect of reducing the grain size and reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

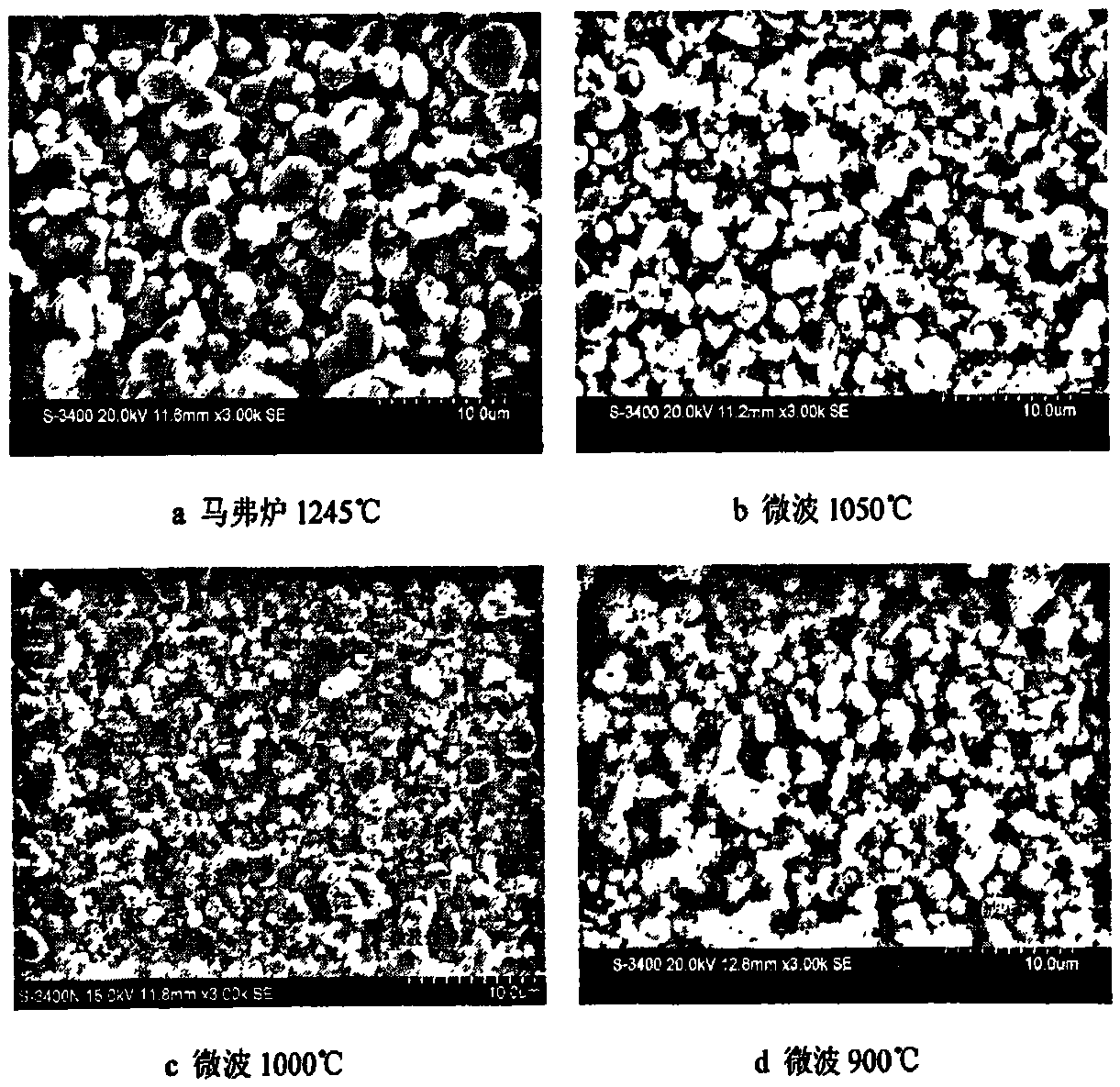

Image

Examples

Embodiment 1

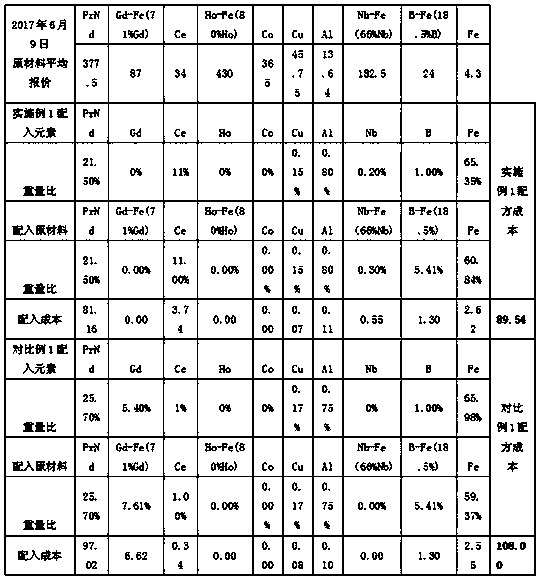

[0030] A low-cost N35 NdFeB magnet with high cerium content, which is prepared by sintering the following components by weight percent: praseodymium neodymium (Pr-Nd): 21.5, cerium (Ce): 11, niobium ﹙Nb﹚: 0.2, aluminum ﹙Al﹚: 0.9, copper ﹙Cu﹚: 0.15, boron ﹙B﹚: 1.0, and the rest is iron ﹙Fe﹚.

[0031] The performance of the prepared N35 NdFeB magnet is as follows when the test temperature is 20°C: remanence Br=11.9kGs, magnetic induction coercive force Hcb=11.5kOe, intrinsic coercive force Hcj=12.8kOe, maximum magnetic energy product (BH) m=33.9MGOe, squareness Hk=98.2%Hcj.

[0032] A method for sintering a low-cost N35 NdFeB magnet with high cerium content, comprising the following steps:

[0033] Step 1. Raw material weighing ratio: Weigh the following raw materials by weight percentage (wt%): praseodymium neodymium (Pr-Nd) 21.5, cerium (Ce) 11, niobium (Nb) 0.2, aluminum (Al) 0.9, copper ( Cu﹚0.15, boron﹙B﹙1.0, the rest is iron﹙Fe﹙;

[0034] Step 2. Smelting cast pieces: P...

Embodiment 2

[0051] A low-cost N35 NdFeB magnet with high cerium content, which is prepared by sintering the following components by weight percent: praseodymium neodymium (Pr-Nd): 12, cerium (Ce): 15, aluminum ﹙Al﹚: 1, boron ﹙B﹚: 1.1, cobalt (Co): 1.2, zirconium (Zr): 0.25, gadolinium (Gd): 1.5, and the rest is iron (Fe).

[0052] The performance of the prepared N35 NdFeB magnet at a test temperature of 20°C is as follows: remanence Br=12.1kGs, magnetic induction coercive force Hcb=12.2kOe, intrinsic coercive force Hcj=12.5kOe, maximum magnetic energy product (BH) m=35.4MGOe, squareness Hk=98.5%Hcj.

[0053] A method for sintering a low-cost N35 NdFeB magnet with high cerium content, comprising the following steps:

[0054] Step 1. Raw material weighing ratio: Weigh the following raw materials by weight percentage (wt%): praseodymium neodymium (Pr-Nd): 12, cerium (Ce): 15, aluminum (Al): 1, boron (B): 1.1, cobalt (Co): 1.2, zirconium (Zr): 0.25, gadolinium (Gd) 1.5, all the other are ir...

Embodiment 3

[0059] A low-cost N35 NdFeB magnet with high cerium content, which is prepared by sintering the following components by weight percent: praseodymium neodymium (Pr-Nd): 27, cerium (Ce): 7, niobium (Nb) 0.5, Copper (Cu): 1, Boron (B): 0.9, Cobalt (Co): 0.6, Zirconium (Zr): 0.5, Gadolinium (Gd): 3, and the rest is Iron (Fe).

[0060] The performance of the prepared N35 NdFeB magnet is as follows when the test temperature is 20°C: remanence Br=13.3kGs, magnetic induction coercive force Hcb=12.9kOe, intrinsic coercive force Hcj=13.3kOe, maximum magnetic energy product (BH) m=37.2MGOe, squareness Hk=98.7%Hcj.

[0061] A method for sintering a low-cost N35 NdFeB magnet with high cerium content, comprising the following steps:

[0062] Step 1. Raw material weighing ratio: Weigh the following raw materials by weight percentage (wt%): praseodymium neodymium (Pr-Nd): 27, cerium (Ce): 7, niobium (Nb) 0.5, copper (Cu): 1 , boron (B): 0.9, cobalt (Co): 0.6, zirconium (Zr): 0.5, gadolinium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

| Magnetic coercive force | aaaaa | aaaaa |

| Intrinsic coercive force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com