Graphene and manganous-manganic oxide composite material and preparation method thereof

A trimanganese tetraoxide composite material and graphene technology, which is applied in the manufacture of manganese oxide/manganese hydroxide, hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as unretrieved patents, and achieve convenient operation, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

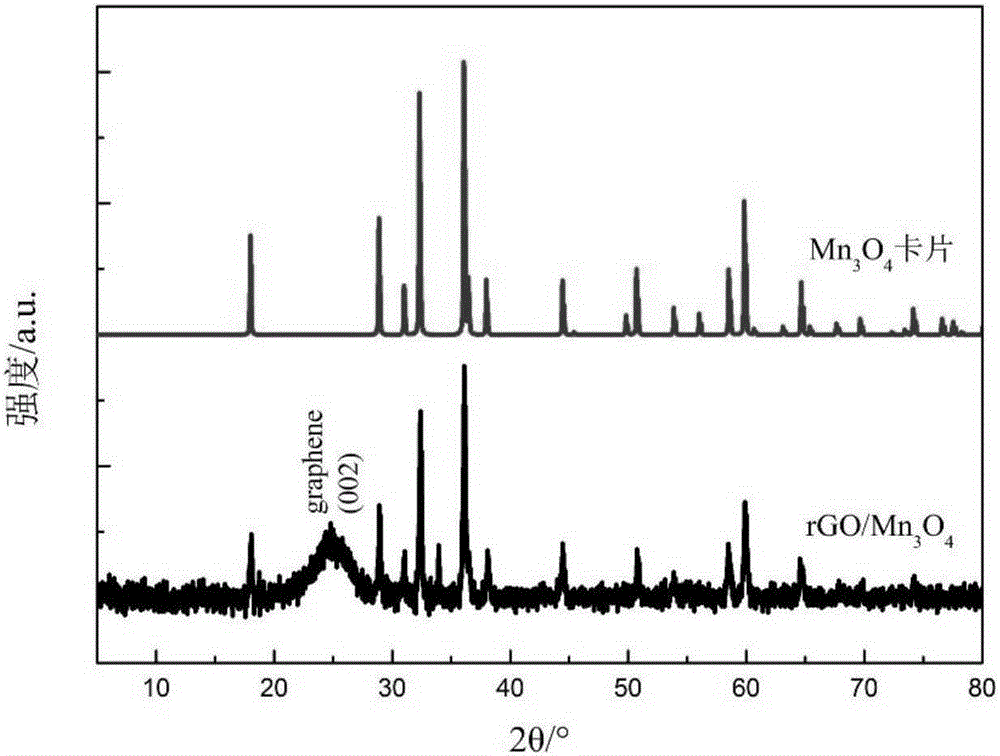

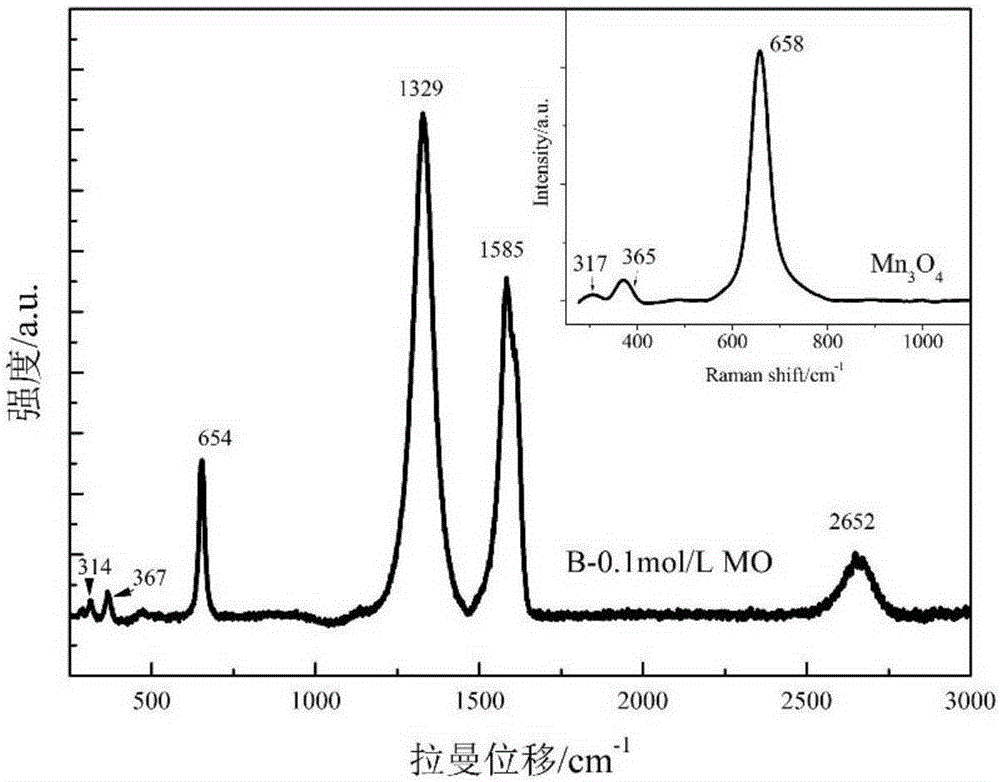

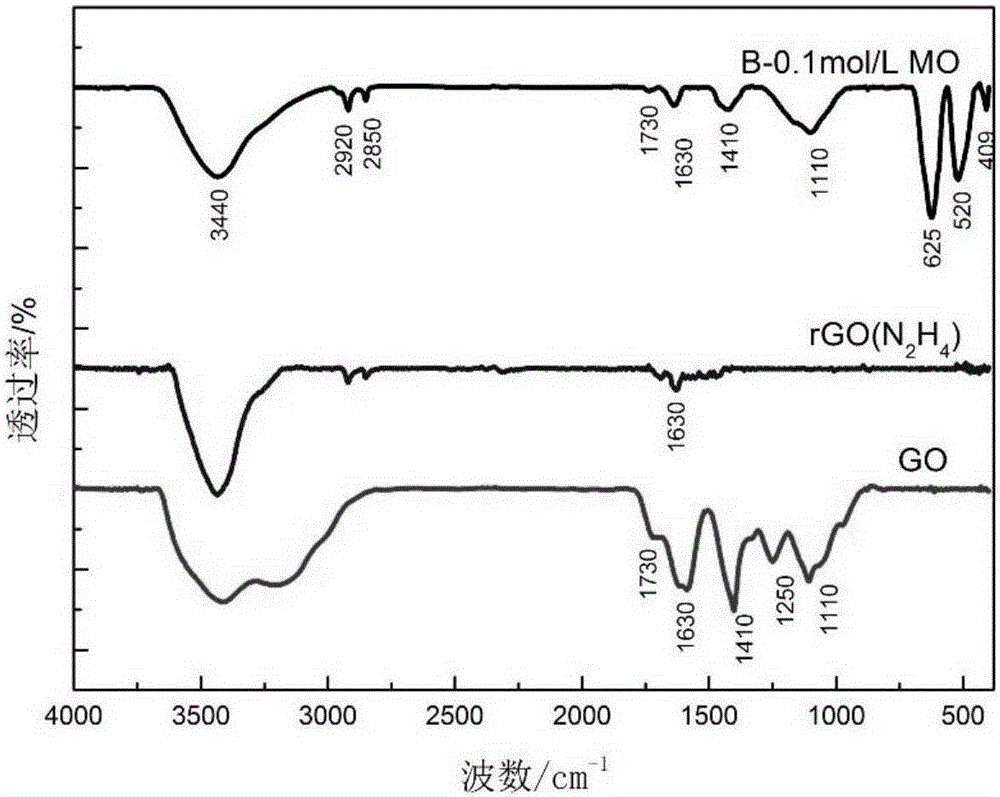

[0034] A preparation method of graphene / trimanganese tetraoxide composite material, comprising the following steps:

[0035] 1) Mix 1g graphite powder with 23mL concentrated H 2 SO 4 (mass concentration is 98wt%, the same below) mixed, stirred at room temperature for 24 hours;

[0036]2) Add 100mg of sodium nitrate in a water bath at 40°C and stir for 5 minutes, then slowly add 1.5g of potassium permanganate in a water bath at less than 5°C and stir for 30 minutes;

[0037] 3) Slowly add 3 mL of distilled water twice, wait for 5 minutes, then add 40 mL of distilled water, raise the temperature to 90°C and stir for 15 minutes;

[0038] 4) Stop the water bath, add 140mL distilled water and 10mL hydrogen peroxide, and stir for 5 minutes to terminate the reaction;

[0039] 5) Use a centrifuge at 7500r / min for 3min, wash with a dilute HCl solution with a mass fraction of 5%, repeat twice, then use a centrifuge at 8000r / min for 3min, wash with distilled water three times until ne...

Embodiment 2

[0052] A preparation method of graphene / trimanganese tetraoxide composite material, comprising the following steps:

[0053] 1) Mix 1g graphite powder with 23mL concentrated H 2 SO 4 Mix and stir at room temperature for 24 hours;

[0054] 2) Add 100mg of sodium nitrate in a water bath at 40°C and stir for 5 minutes, then slowly add 1.5g of potassium permanganate in a water bath at less than 5°C and stir for 30 minutes;

[0055] 3) Slowly add 3 mL of distilled water twice, wait for 5 minutes, then add 40 mL of distilled water, raise the temperature to 90°C and stir for 15 minutes;

[0056] 4) Stop the water bath, add 140mL distilled water and 10mL hydrogen peroxide, and stir for 5 minutes to terminate the reaction;

[0057] 5) Use a centrifuge at 7500r / min for 3min, wash with a dilute HCl solution with a mass fraction of 5%, repeat twice, then use a centrifuge at 8000r / min for 3min, wash with distilled water three times until neutral;

[0058] 6) Disperse the precipitate in...

Embodiment 3

[0067] A preparation method of graphene / trimanganese tetraoxide composite material, comprising the following steps:

[0068] 1) Mix 1g graphite powder with 23mL concentrated H 2 SO 4 Mix and stir at room temperature for 24 hours;

[0069] 2) Add 100mg of sodium nitrate in a water bath at 40°C and stir for 5 minutes, then slowly add 1.5g of potassium permanganate in a water bath at less than 5°C and stir for 30 minutes;

[0070] 3) Slowly add 3 mL of distilled water twice, wait for 5 minutes, then add 40 mL of distilled water, raise the temperature to 90°C and stir for 15 minutes;

[0071] 4) Stop the water bath, add 140mL distilled water and 10mL hydrogen peroxide, and stir for 5 minutes to terminate the reaction;

[0072] 5) Use a centrifuge at 7500r / min for 3min, wash with a dilute HCl solution with a mass fraction of 5%, repeat twice, then use a centrifuge at 8000r / min for 3min, wash with distilled water three times until neutral;

[0073] 6) Disperse the precipitate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com