Spherical manganic manganous oxide and its preparation method

A technology of trimanganese tetraoxide and spherical shape, which is applied in the direction of manganese oxide/manganese hydroxide, etc. It can solve the problems of small specific gravity, inability to use lithium manganese oxide, high impurity content, etc., to achieve enhanced application, improved cycle performance and high temperature performance , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

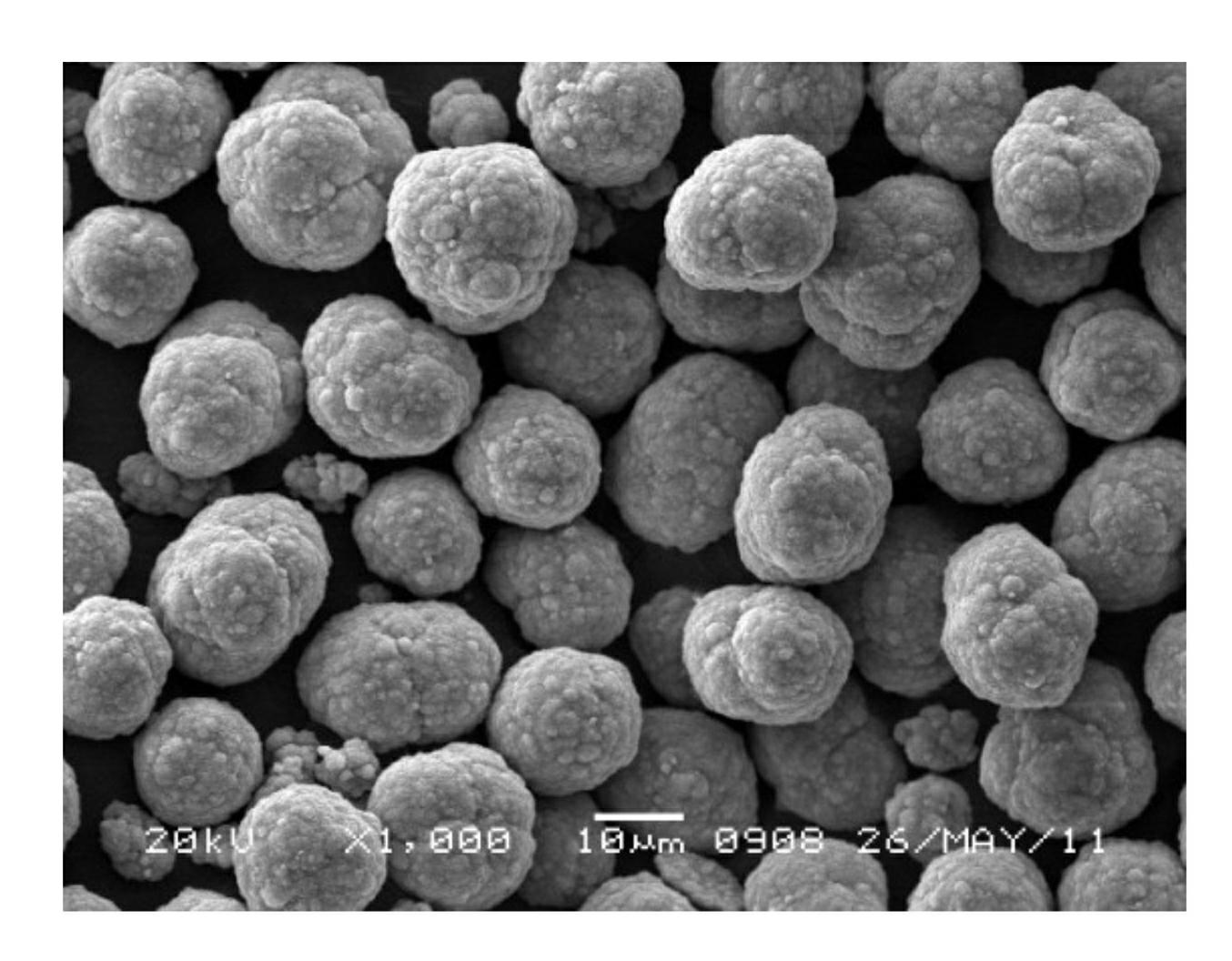

[0034] a kind of like figure 1 The spherical trimanganese tetraoxide of the present invention shown, the D of the spherical trimanganese tetraoxide 50 The particle size is 11.5μm, and the tap density is 2.2g / cm 3 .

[0035] Prepare 10L of manganese sulfate solution with a divalent manganese ion concentration of 60g / L with pure water, then weigh 40g of absolute ethanol and add it to the manganese sulfate solution and stir evenly; prepare a sodium hydroxide solution with a concentration of 120g / L with pure water 10L, weigh 160g of ammonia water with a mass fraction of 25% and add it to the sodium hydroxide solution and stir evenly; according to the flow rate of manganese sulfate 500ml / h and the molar ratio of manganese ions and sodium hydroxide as 1:2, use a metering pump Add manganese sulfate solution and sodium hydroxide solution into a stirred reactor with a volume of 8L, control the reaction temperature to 60°C, and the pH value of the reaction solution to 10, and at the s...

Embodiment 2

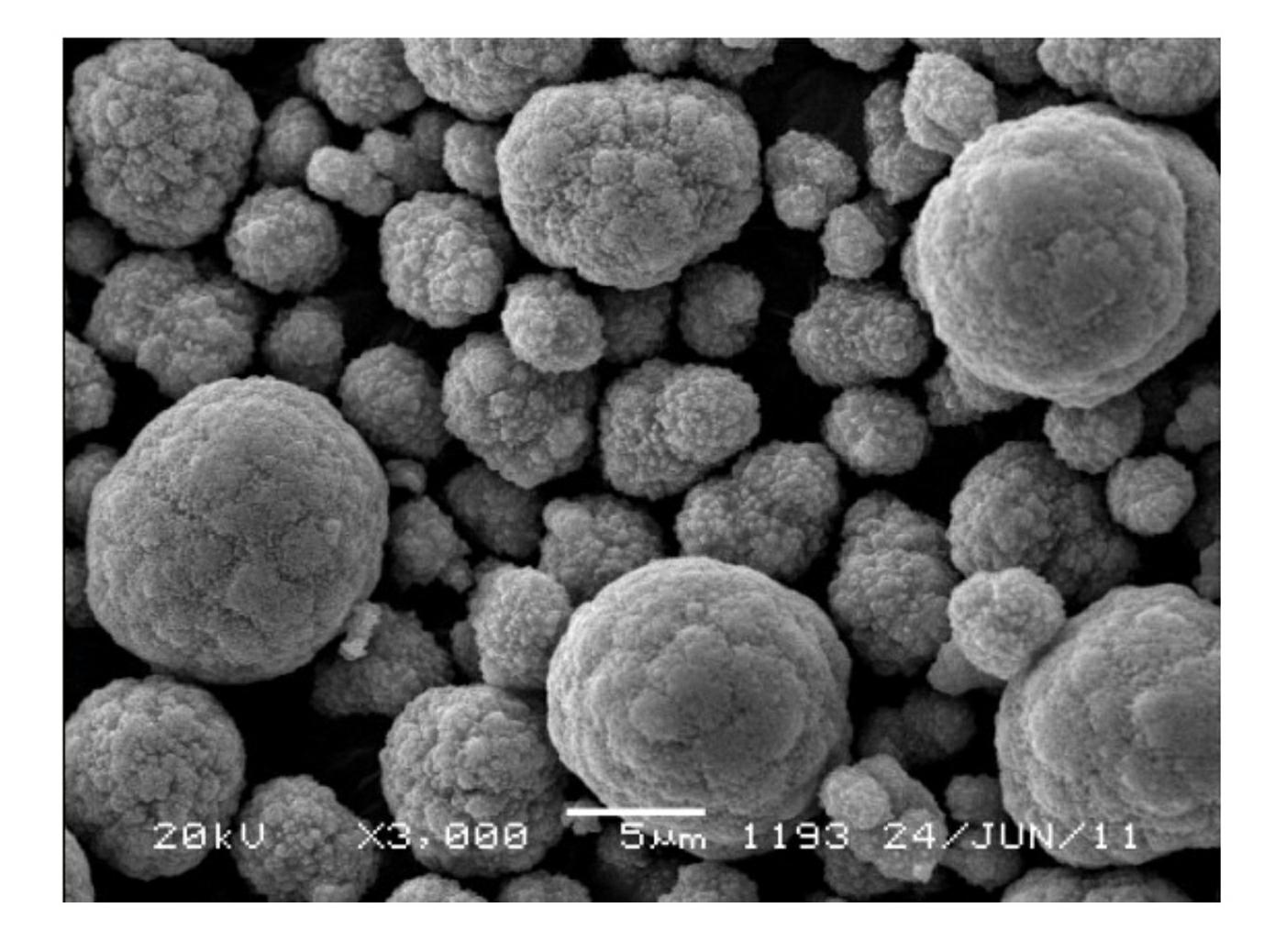

[0038] a kind of like figure 2 The spherical trimanganese tetraoxide of the present invention shown, the D of the spherical trimanganese tetraoxide 50 The particle size is 7.1μm, and the tap density is 2.1g / cm 3 .

[0039] Use pure water to prepare 10L of manganese sulfate solution with a divalent manganese ion concentration of 90g / L, weigh 36g of disodium EDTA and 10.6g of sodium fluoride, add them to the manganese sulfate solution and stir evenly; prepare a concentration of 200g / L with pure water 10L of sodium hydroxide solution, according to the flow rate of manganese sulfate 500ml / h and the molar ratio of manganese ions and sodium hydroxide as 1:2, add manganese sulfate solution and sodium hydroxide solution to the reactor with a volume of 8L by metering pump In the process, the temperature of the reaction is controlled at 70°C, the pH of the reaction solution is 9.5, and at the same time, a sufficient amount of air is passed to oxidize the precipitate, and the product ...

Embodiment 3

[0042] A kind of spherical trimanganese tetraoxide of the present invention, the D of the spherical trimanganese tetraoxide 50 The particle size is 10.1μm, and the tap density is 2.2g / cm 3 .

[0043] Use pure water to prepare 20L of manganese nitrate solution with a divalent manganese ion concentration of 145g / L, weigh 38g disodium EDTA and 20g ethylene glycol and add them to the manganese nitrate solution and stir evenly; then use pure water to prepare a concentration of 200g / L 30L of sodium hydroxide solution, add 60g of ethylenediamine and stir evenly; according to the flow rate of manganese nitrate 500ml / h and the molar ratio of manganese ions and sodium hydroxide as 1:2, the manganese nitrate solution and hydroxide Add the sodium solution into a stirred reactor with a volume of 8 L, control the reaction temperature to 70°C, and control the pH value of the reaction solution to 10, and at the same time pass a sufficient amount of air to oxidize the precipitate, and the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com