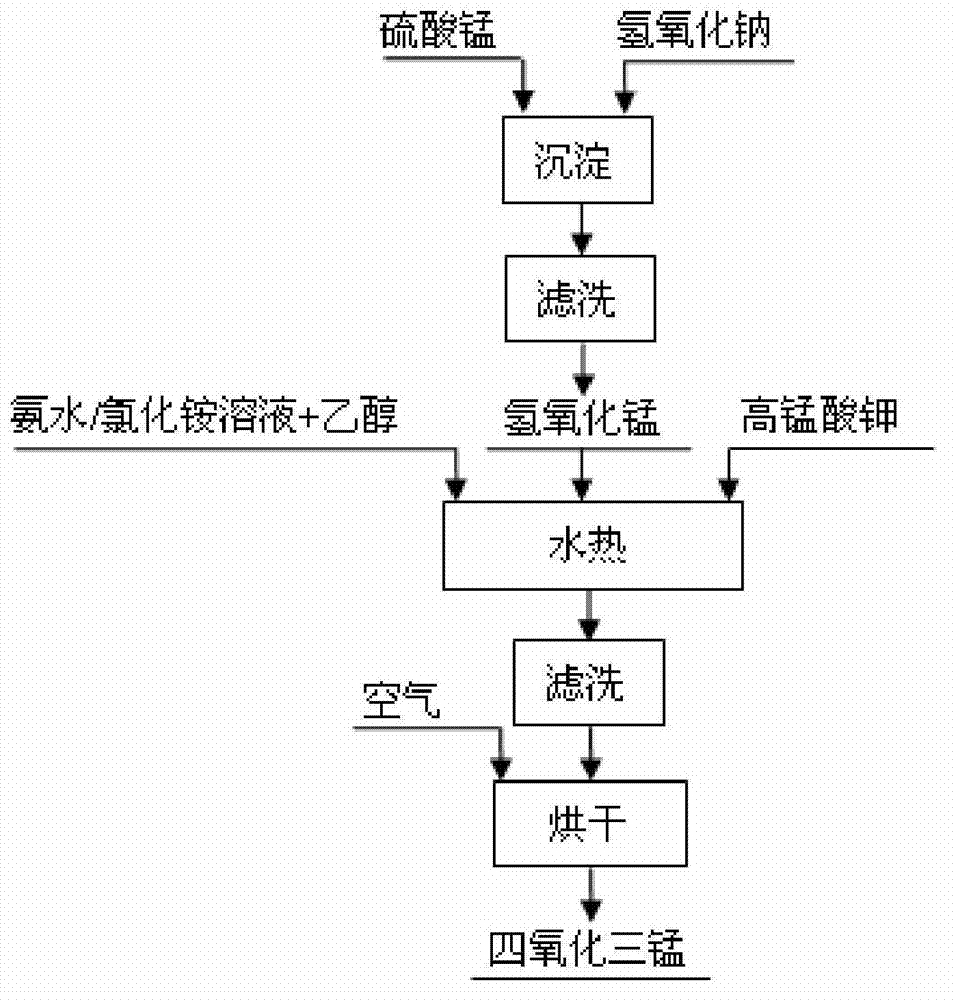

Method for preparing manganous manganic oxide

A technology of manganese tetroxide and manganese hydroxide, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of high energy consumption, general physical properties and large consumption in the preparation process, achieve simple process route, improve operating environment, The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

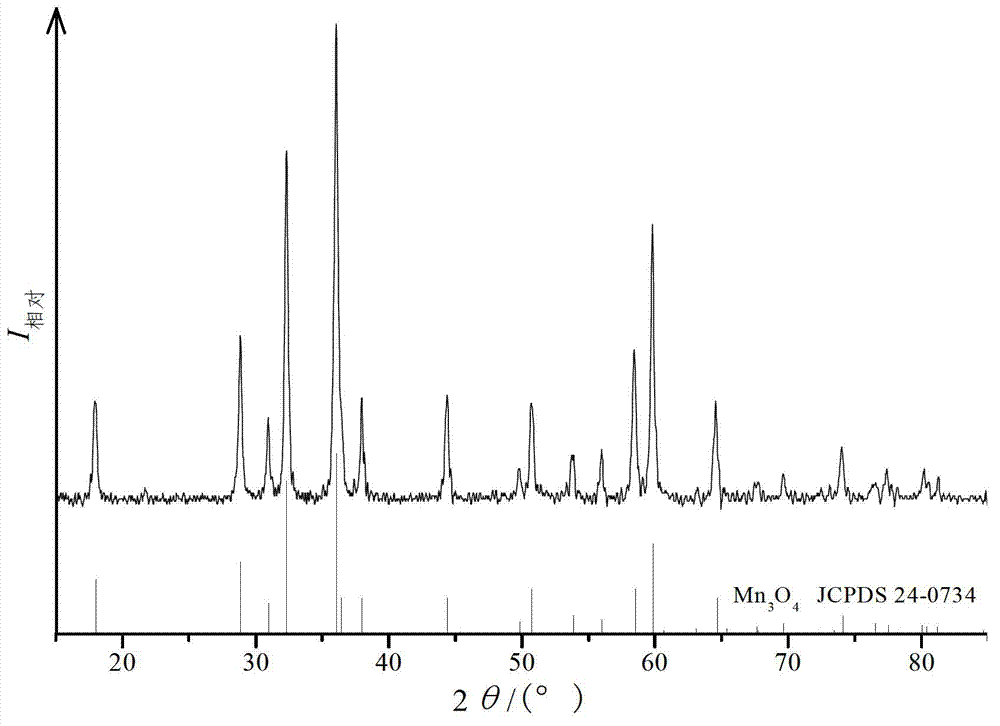

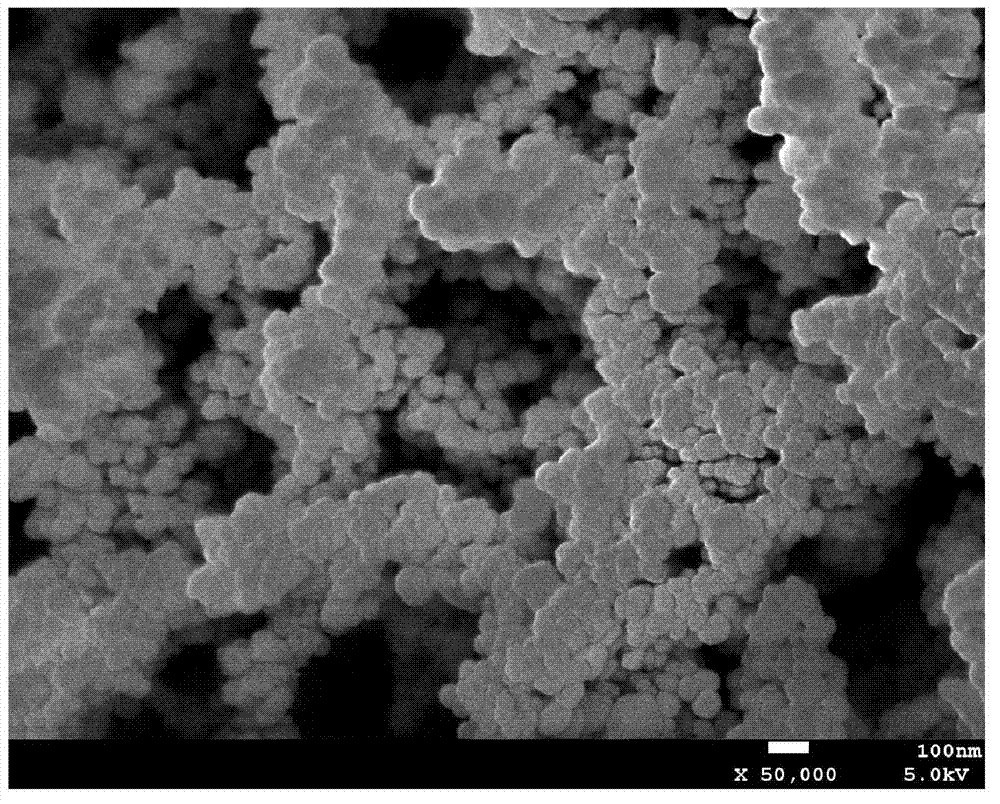

Embodiment 1

[0055] Using analytically pure manganese sulfate as raw material, the manganese sulfate content is greater than 99%, the iron content is 0.0005%, and the nickel content is 0.0200%. Take 20g of manganese sulfate to prepare a 100g / L solution, 9g of sodium hydroxide to prepare a 45g / L solution, at 20°C, under the condition of stirring, add the above two solutions dropwise to 100mL water at the same flow rate at the same time, after the dropwise addition, use pHS-3C laboratory acidity meter test and add sodium hydroxide solution to pH 8.5, let it stand for about half an hour, separate the turbid liquid from solid and analyze the Mn in the filtrate 2+ Concentration, the precipitation rate of manganese sulfate is 97.8%; under 40kHz ultrasonic conditions, filter again after slurrying with deionized water, repeat several times until the filtrate is saturated with BaCl 2 solution not detected Obtain the precursor manganese hydroxide; take 40mL of ammonia water / ammonium chloride solut...

Embodiment 2

[0057] Using analytically pure manganese sulfate as raw material, the manganese sulfate content is greater than 99%, the iron content is 0.0005%, and the nickel content is 0.0200%. Take 20g of manganese sulfate to prepare a 100g / L solution, 9g of sodium hydroxide to prepare a 45g / L solution, add the above two solutions dropwise to 100mL of water at the same flow rate at 30°C under stirring conditions, after the dropwise addition is completed, use pHS-3C laboratory acidity meter test and add sodium hydroxide solution to pH 9.0, let it stand for about half an hour, separate the turbid liquid from solid and analyze the Mn in the filtrate 2+ Concentration, the precipitation rate of manganese sulfate is 99.4%; under 40kHz ultrasonic conditions, filter again after slurrying with deionized water, repeat several times until the filtrate is saturated with BaCl 2 solution not detected Obtain the precursor manganese hydroxide; take 40mL of ammonia water / ammonium chloride solution (the ...

Embodiment 3

[0059] Using industrial manganese sulfate as raw material, the content of manganese sulfate is 98.2%, the content of iron is 0.0010%, the content of calcium is 0.0180%, and the content of magnesium is 0.1800%. Take 20g of manganese sulfate to prepare a 100g / L solution, 9g of sodium hydroxide to prepare a 45g / L solution, add the above two solutions dropwise to 100mL of water at the same flow rate at 30°C under stirring conditions, after the dropwise addition is completed, use pHS-3C laboratory acidity meter test and add sodium hydroxide solution to pH 9.0, let it stand for about half an hour, separate the turbid liquid from solid and analyze the Mn in the filtrate 2+ Concentration, the precipitation rate of manganese sulfate is 99.4%; under 40kHz ultrasonic conditions, filter again after slurrying with deionized water, repeat several times until the filtrate is saturated with BaCl 2 solution not detected Obtain the precursor manganese hydroxide; take 40mL of ammonia water / amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com